Processing device for polishing special material

A processing device and special material technology, applied in the field of machinery, can solve the problems of high work intensity, time-consuming, low efficiency, etc., and achieve the effect of improving processing efficiency and high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

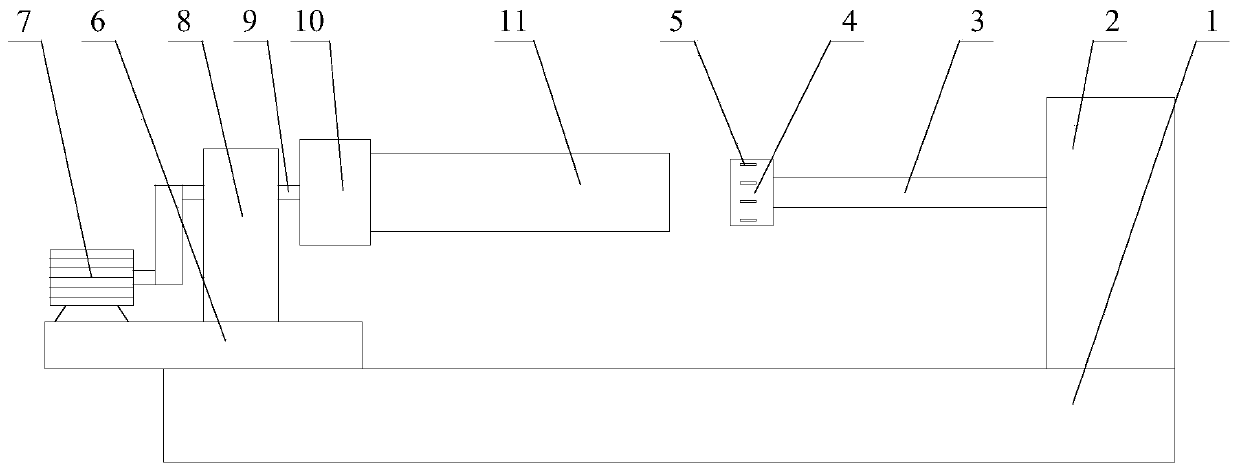

[0025] Such as figure 1 As shown, a processing device for polishing special materials designed by the present invention includes a base 1 and a grinding wheel 4, and the diameter of the grinding wheel 4 is determined according to the inner diameter of the workpiece to be processed, and is adapted to it. A fixed platform 2 is fixedly installed on one side of the base 1 , a fixed rod 3 is fixedly mounted on the fixed platform 2 , and the grinding wheel 4 is installed at the end of the fixed rod 3 . The device grinding wheel 4 of the present invention is in a fixed state during processing. The other side of the base 1 is installed with a stepping table 6 capable of reciprocating axially along the fixed rod 3, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com