Stirring Process Based on Solder Paste Production

A stirring process and solder paste technology, which is applied to mixer accessories, mixers with rotating stirring devices, dissolving, etc., can solve problems such as uneven mixing of solder paste and flux, reduce the amount of flux, reduce air, The effect of reducing air bubbles

Active Publication Date: 2019-08-02

GUANGDONG TIANGAO TECH CO LTD

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The purpose of the present invention is to provide a stirring process based on solder paste production to solve the problem of uneven mixing of solder paste and flux during the solder paste stirring process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

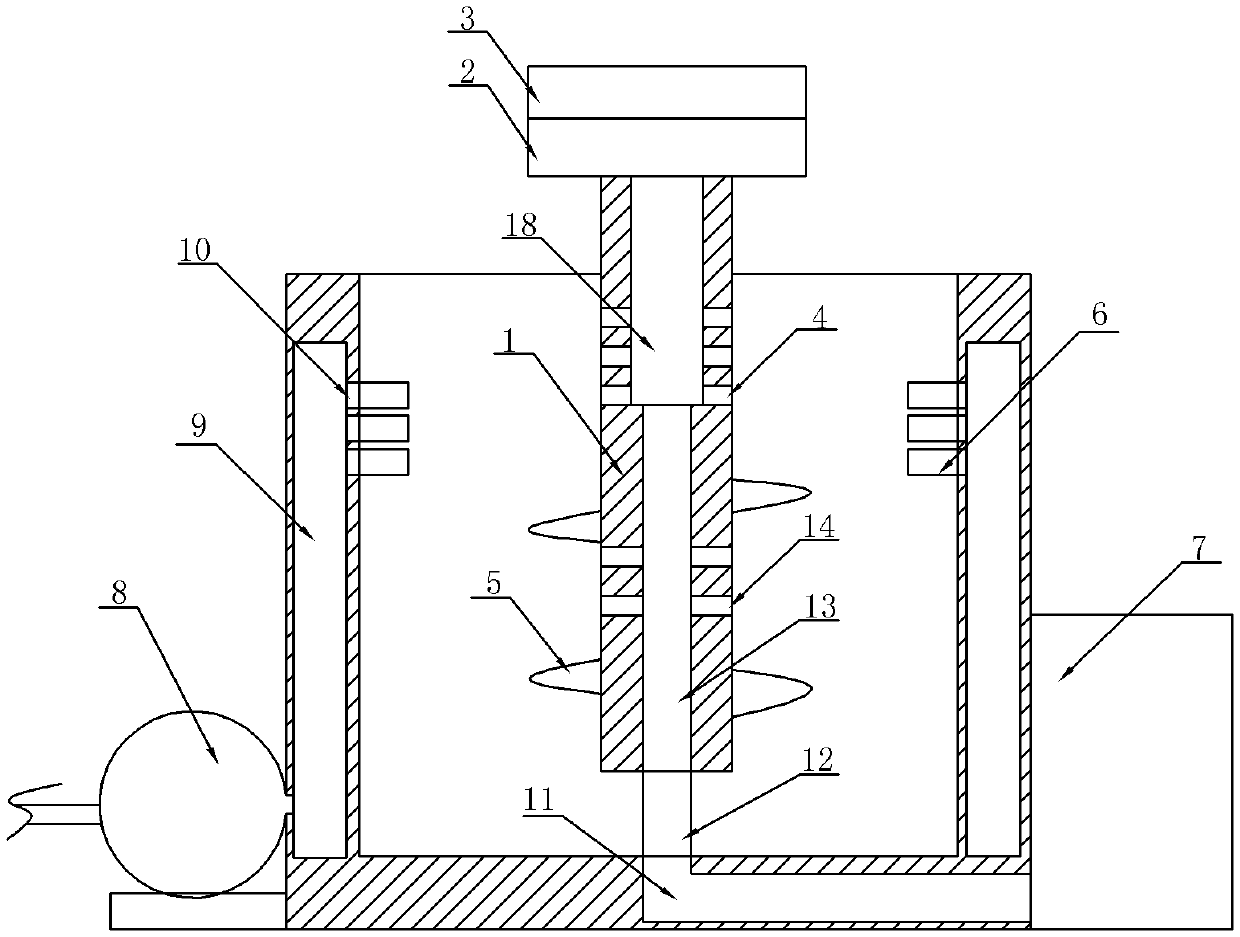

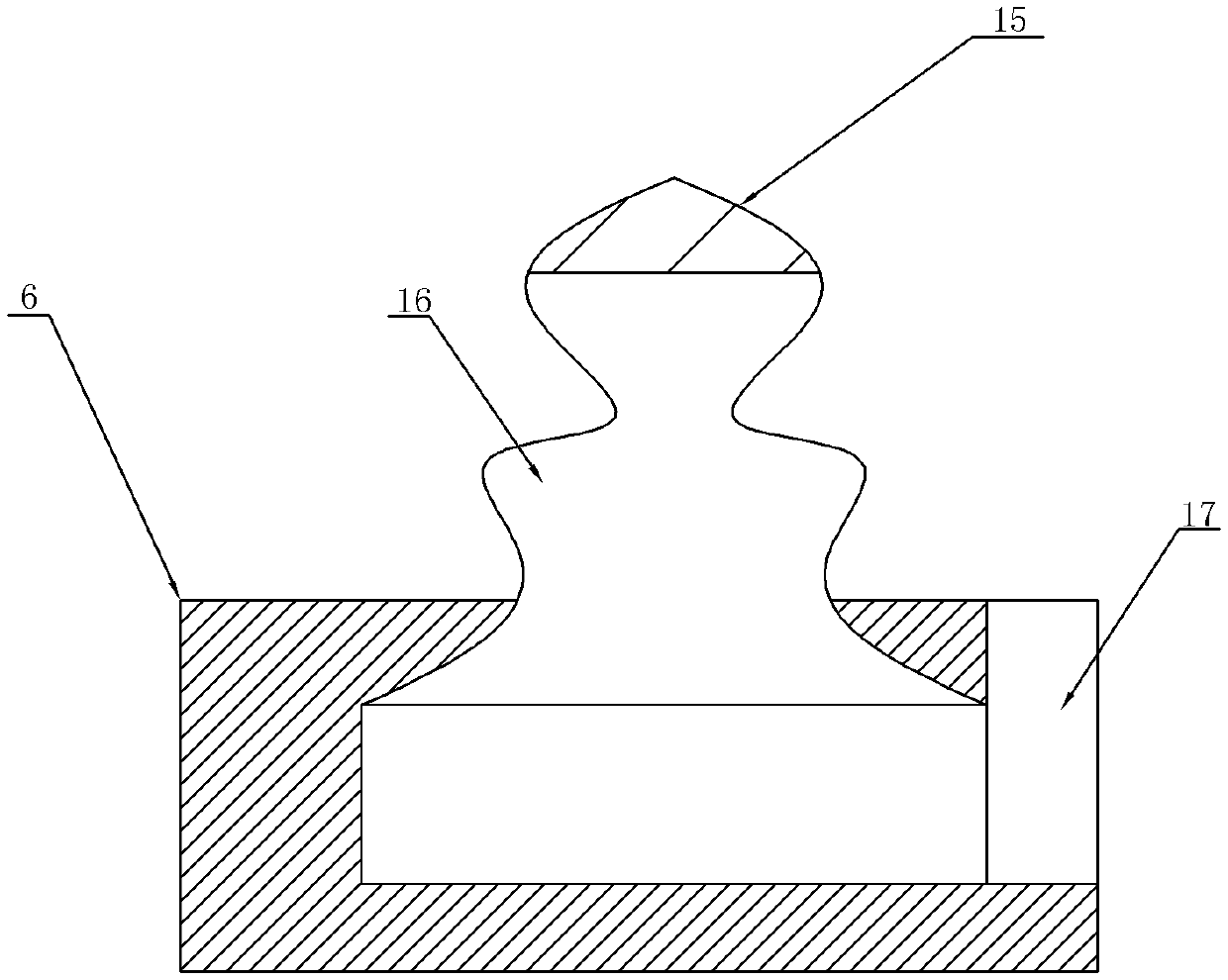

The invention relates to the technical field of solder paste production and processing, and discloses a stirring process based on solder paste production, which is carried out using a solder paste stirring device. The solder paste stirring device includes a stirring barrel, a stirring shaft, a discharge box, a frame and a motor, and the stirring barrel It is fixedly installed on the frame, the stirring shaft is installed in the mixing barrel, the discharge box is located above the mixing barrel and is fixedly connected with the lower part of the motor, and the motor is fixed on the frame; there is an air bag on one side of the mixing barrel, The bucket is provided with an air cavity connected with the air bag, and the side wall of the mixing tank is provided with a dispersing mechanism. The dispersing mechanism includes a fixing seat, a rubber bag and an extruded part. The air outlet is facing the air outlet one-way valve of the stirring shaft. The extruded part is fixedly installed on the rubber bag, and the rubber bag is connected with the inner cavity. The upper part of the stirring shaft is provided with a material chamber connected with the discharge box. hole. The invention has good stirring effect and reduces the generation of solder paste bubbles.

Description

technical field [0001] The invention relates to the technical field of solder paste production and processing, in particular to a stirring process based on solder paste production. Background technique [0002] Solder paste is a paste mixture formed by mixing tin powder, flux and other surfactants, thixotropic agents, etc. Solder paste is mainly used in the soldering of electronic components such as surface resistors, capacitors, and ICs of PCB boards in the SMT industry, and has certain economic value. [0003] In the solder paste production process, it is necessary to mix tin powder and flux by stirring, and add a large amount of tin powder directly into the flux. Failure to stir evenly will cause some tin powder to fail to contact the flux in time. At the same time, during the storage of tin powder, the combination of water and tin powder will produce some hardened tin powder, hardened tin powder and flux are not easy to mix evenly, there is a certain gap between solder ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B01F7/24B01F3/20B01F15/02B01F15/06B22F9/04B01F23/70

Inventor 张锦镜

Owner GUANGDONG TIANGAO TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com