Soil screening equipment for soil remediation

A technology for soil screening and soil remediation, applied in the field of soil remediation, can solve the problems of high screening pressure and unsatisfactory screening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

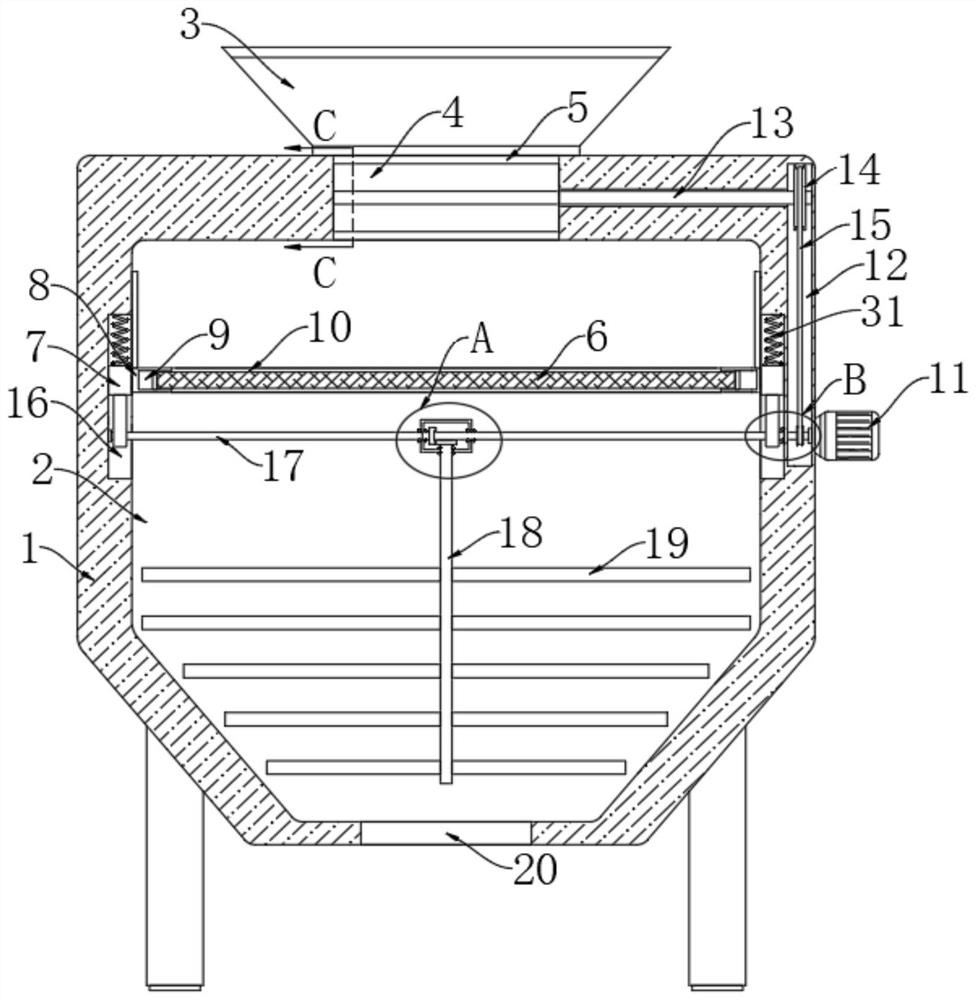

[0025] refer to Figure 1-4 , a soil screening equipment for soil remediation, comprising a shell 1, a treatment chamber 2 is arranged in the shell 1, a discharge port 20 is arranged at the inner bottom of the treatment chamber 2, and a feed port is arranged at the inner top of the treatment chamber 2 , a feeding hopper 3 is installed on the upper end of the shell 1, and the feeding hopper 3 is communicated with the upper end of the feeding port, and a cylindrical cavity 5 is arranged in the shell 1, and the cylindrical cavity 5 is located above the processing chamber 2;

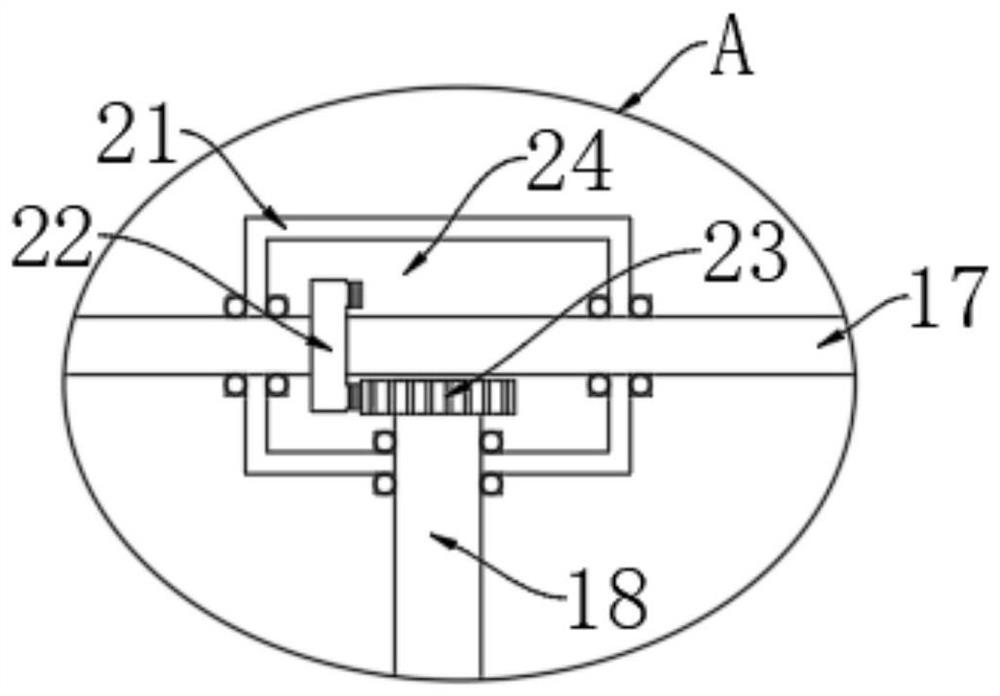

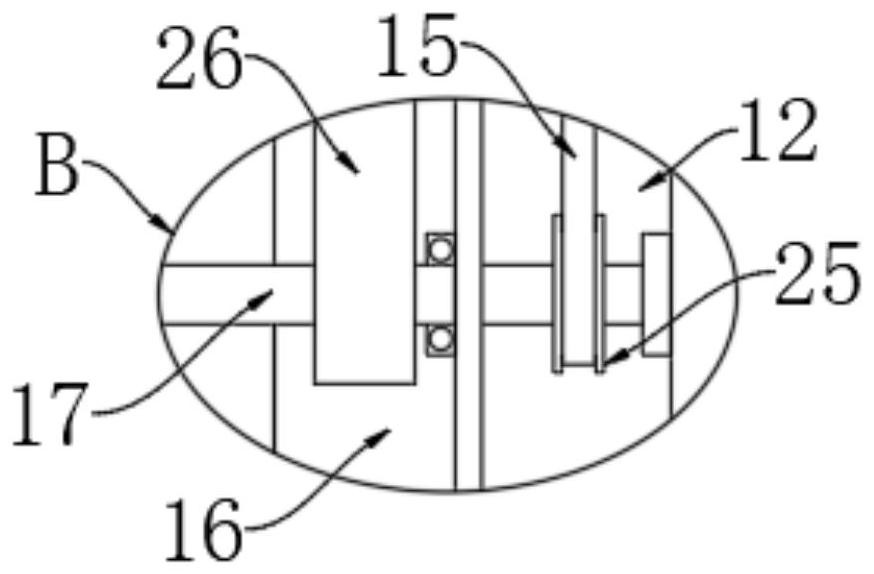

[0026] Vibration screening mechanism. The vibration screening mechanism includes a drive motor 11 installed on the right side of the housing 1. The end of the output shaft of the drive motor 11 extends into the processing chamber 2, and is fixedly connected with a first rotating rod 17. Both sides of the processing chamber 2 The inner wall is provided with a chute 16, and the two chute 16 are provided with a...

Embodiment 2

[0034] refer to Figure 5-7 , the difference between this embodiment and Embodiment 1 is that the two sides of the screen plate 6 are fixedly connected with sliding plates 27, the two sliding plates 27 are respectively located in the two installation slots 9, and the sliding plate 27 located on the left The left side of the processing chamber 2 is elastically connected to the left inner wall of the corresponding installation slot 9 through the second connecting spring 30. A sliding rod 28 is vertically arranged in the processing chamber 2. A plurality of magnetic blocks 29 are embedded in sequence, the sliding plate 27 located on the right side has magnetism, and the adjacent surfaces of the sliding plate 27 and the plurality of magnetic blocks 29 are identical and repel.

[0035] In this embodiment, when the connecting bar 8 moves up and down, the magnetic sliding plate 27 on the right side is intermittently close to the plurality of magnetic blocks 29 . The right sliding pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com