Multistage integrated hydrodynamic cyclone separator

A cyclone separator and fluid power technology, which is applied in the direction of separating sediments by centrifugal force, can solve the problems of poor separation effect, and achieve the effects of centralized dredging, improved stability, and improved removal efficiency

Inactive Publication Date: 2012-06-27

BEIJING UNIVERSITY OF CIVIL ENGINEERING AND ARCHITECTURE

View PDF7 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The purpose of the present invention is to provide a practical multi-stage integrated hydrodynamic cyclone separator with optimized treat

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

| Slope | aaaaa | aaaaa |

| Cone angle | aaaaa | aaaaa |

Login to View More

Abstract

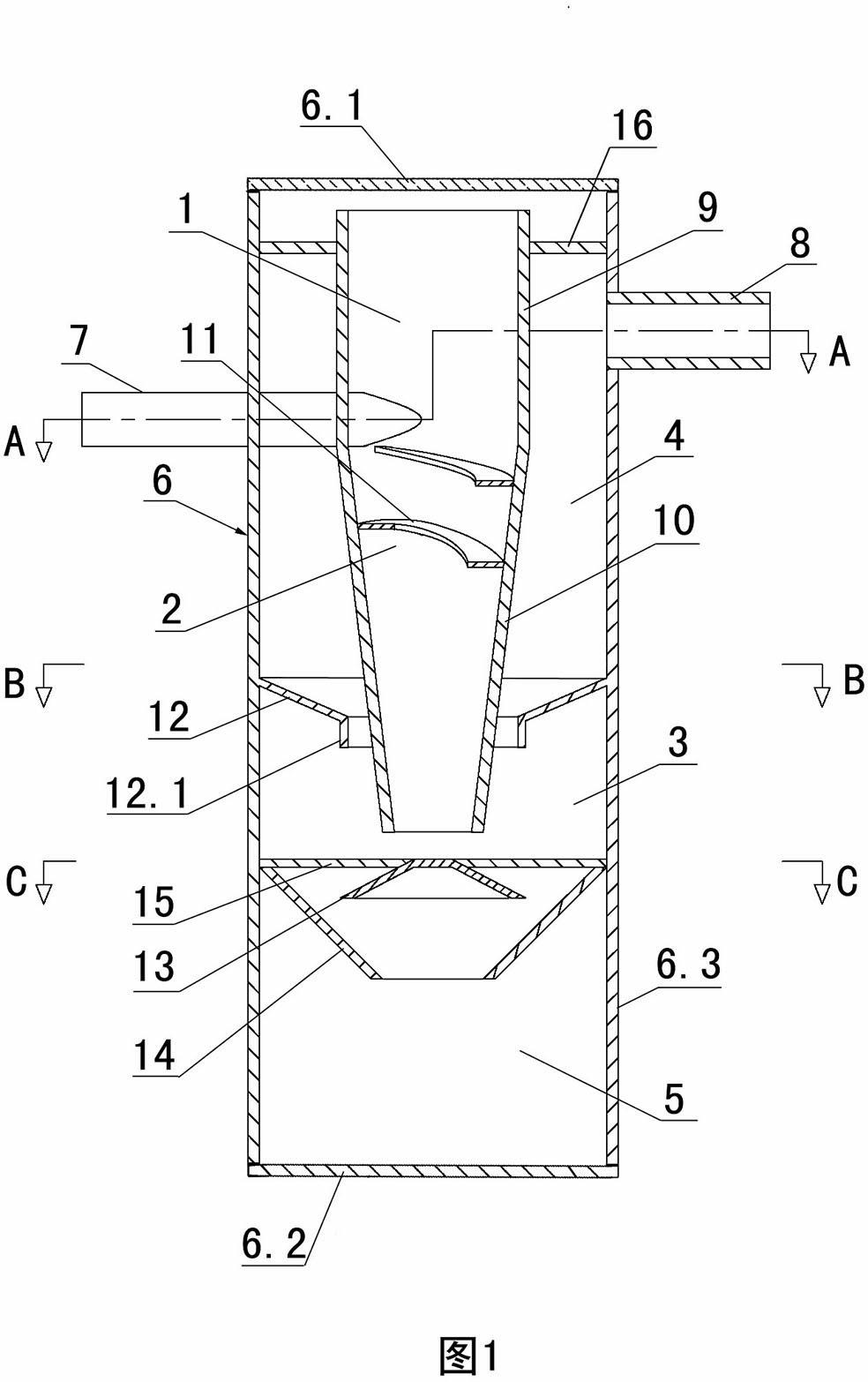

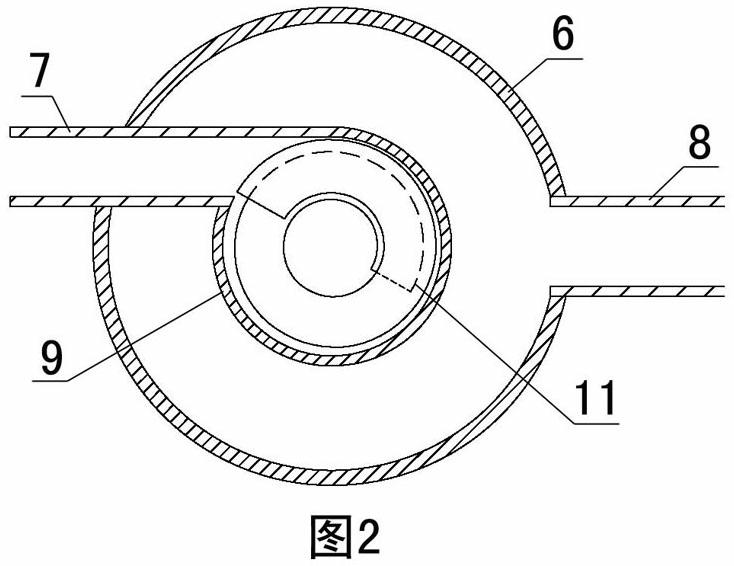

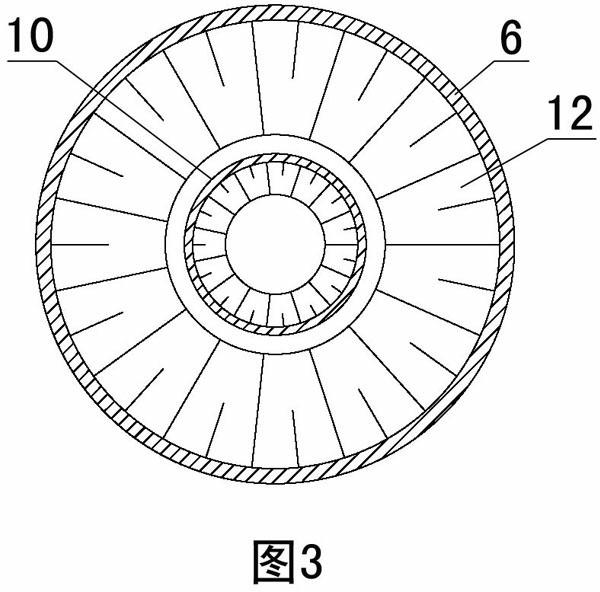

The invention provides a multistage integrated hydrodynamic cyclone separator. The cyclone separator comprises a cylindrical shell and a tangential inlet pipe and an outlet pipe connected with the cylindrical shell; the cylindrical shell comprises a top cover, a bottom plate and a side wall, wherein, the top cover is a detachable cover plate or a partially perforated cover plate; a cylindrical guide plate is arranged at the center of the upper part in the cylindrical shell and is connected with the side wall of the cylindrical shell through a cylindrical guide plate support frame, the lower end of the cylindrical guide plate is connected with a tapered guide plate which has a larger diameter at its upper part and a smaller diameter at its lower part, a separation chamber inclined baffle plate is arranged in a cavity between the tapered guide plate and the side wall, and a sediment storage chamber separation baffle plate is provided below the tapered guide plate and on the side wall of the cylindrical shell. The cyclone separator has three-stage separation chambers which are integrated into one, so the cyclone separator provided in the invention has an improved removal effect on particles and enhanced effective treating ability compared to conventional cyclone separators.

Description

technical field [0001] The invention relates to a hydrodynamic cyclone separator used for rainwater treatment, in particular to a purification treatment of solid suspended matter and floating matter in rainwater runoff or solid suspended matter control and sewage treatment of rainwater combined drainage system A hydrodynamic cyclone separator for pre-treatment of the process. Background technique [0002] The development history of hydrodynamic cyclone separators abroad can be traced back to the 1960s. Bernard Smisson built and tested the effect of cyclone separation facilities in Bristol, England, and used them to deal with the overflow pollution control of combined pipelines. The first generation of hydroseparators can effectively retain 70% of the total pollution (Smisson, 1967). After development and commercialization since the 1980s, hydrodynamic cyclone separators have been tested and applied in Europe, North America, Japan and other regions. (Brombach, 1992; Hedges ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D21/26

Inventor 李俊奇吴熙车伍王建龙王文海

Owner BEIJING UNIVERSITY OF CIVIL ENGINEERING AND ARCHITECTURE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com