Patents

Literature

85results about How to "Easily lost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ice-temperature air adjusting fresh-keeping minced fillet foodstuff and production process thereof

InactiveCN1545931AExtend freshnessGrowth inhibitionFood preservationFood preparationGrass carpChemistry

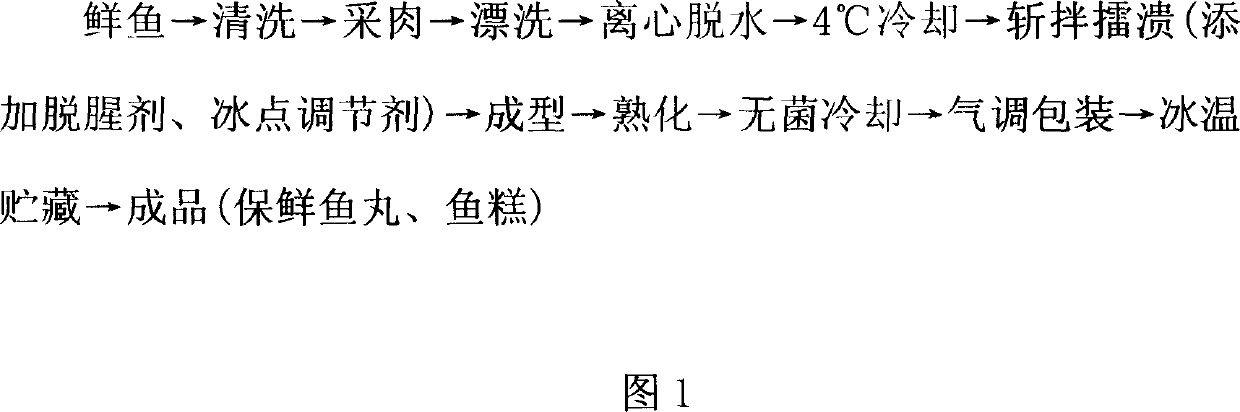

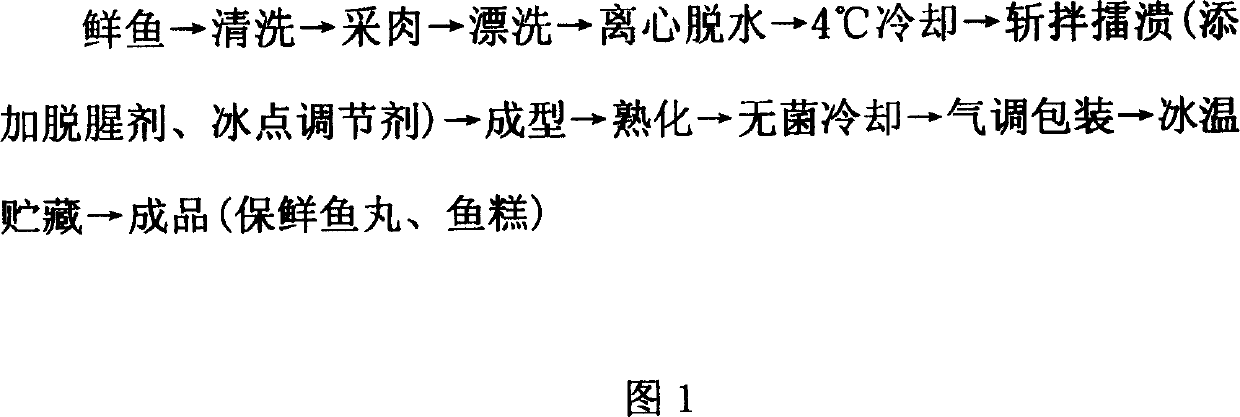

The invention relates to a process for preparing minced fish food and products by using meat of fresh water fish such as silver carp, grass carp as raw material, and table salt, modified starch, konjac glucomannan, white sugar, smell removing agent as auxiliary material. The preparing process comprises smell removing, freezing point adjustment, germ-free cooling down, air regulation packaging, and ice temperature storage.

Owner:HUAZHONG AGRI UNIV

Ice temperature gas regulation fresh-keeping water-cooking minced fish octopus bolus ball

InactiveCN101496617AExtend freshnessGrowth inhibitionMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsIce waterCooling chamber

The invention relates to an ice-temperature modified atmosphere preserved water cooked minced fillet octopus ball. The ice-temperature modified atmosphere preserved water cooked minced fillet octopus ball is prepared by heating, boiling and forming minced fillet, starch, emulsified slurry, egg white, starch glue, sodium glutamate, granulated sugar, a taste promoter, sugar essence, Tarinsan, Tarilin, seafood essence, an octopus head, ice water and muddy garlic. The preparation method comprises the following steps: placing 33kg of refrigerated minced fillet into a kneader for kneading; then adding 2.1ks of salt, 22ks of starch, 24ks of emulsified slurry, 1.1ks of egg white, 0.18ks of starch glue, 1.1ks of sodium glutamate, 2ks of granulated sugar, 0.44ks of taste promoter, 0.03ks of sugar essence, 0.1ks of Tarinsan, 0.1ks of Tarilin, 0.5ks of seafood essence, 9ks of octopus head, 3.6ks of ice water and 1.8ks of muddy garlic; kneading and mixing the raw materials evenly to prepare the fish balls or fish cake; then placing the fish balls or fish cake into a sterile cooling chamber for cooling down the fish balls or fish cake; carrying out the vacuum blowup packaging of the cooled fish balls or fish cake; and then storing the fish balls or fish cake in a non-frozen state at a temperature of between 0 and 3 DEG C below zero so as to reach the aim of preservation.

Owner:周黎明

TC4 titanium alloy bar material forging method

The invention provides a TC4 titanium alloy bar material forging method. The method comprises the following steps that a titanium alloy ingot is heated and subjected to drawing-out forging, and then atitanium alloy forged blank is obtained; the titanium alloy forged blank is heated to 10 DEG C to 50 DEG C below beta-phase point-change temperature, precise forging is conducted, and then a TC4 titanium alloy bar material is obtained, wherein an induction heating technology is adopted in the precise forging process for enabling temperature of the titanium alloy forged blank to be kept 10 DEG C to 50 DEG C below the beta-phase point-change temperature. According to the TC4 titanium alloy bar material forging method, the technology during the precise forging process is improved according to the problems found in the researching process, and the induction heating technology is adopted in the precise forging process for temperature compensation to enable the temperature of the titanium alloyforged blank to be kept 10 DEG C to 50 DEG C below the beta-phase point-change temperature, so that the problem that the quality of products is affected due to improper control over the discharging time in the precise forging process is avoided, structure uniformity and stable performance of the TC4 titanium alloy bar material are guaranteed, and the quality of the products is reliable.

Owner:湖南湘投金天钛业科技股份有限公司

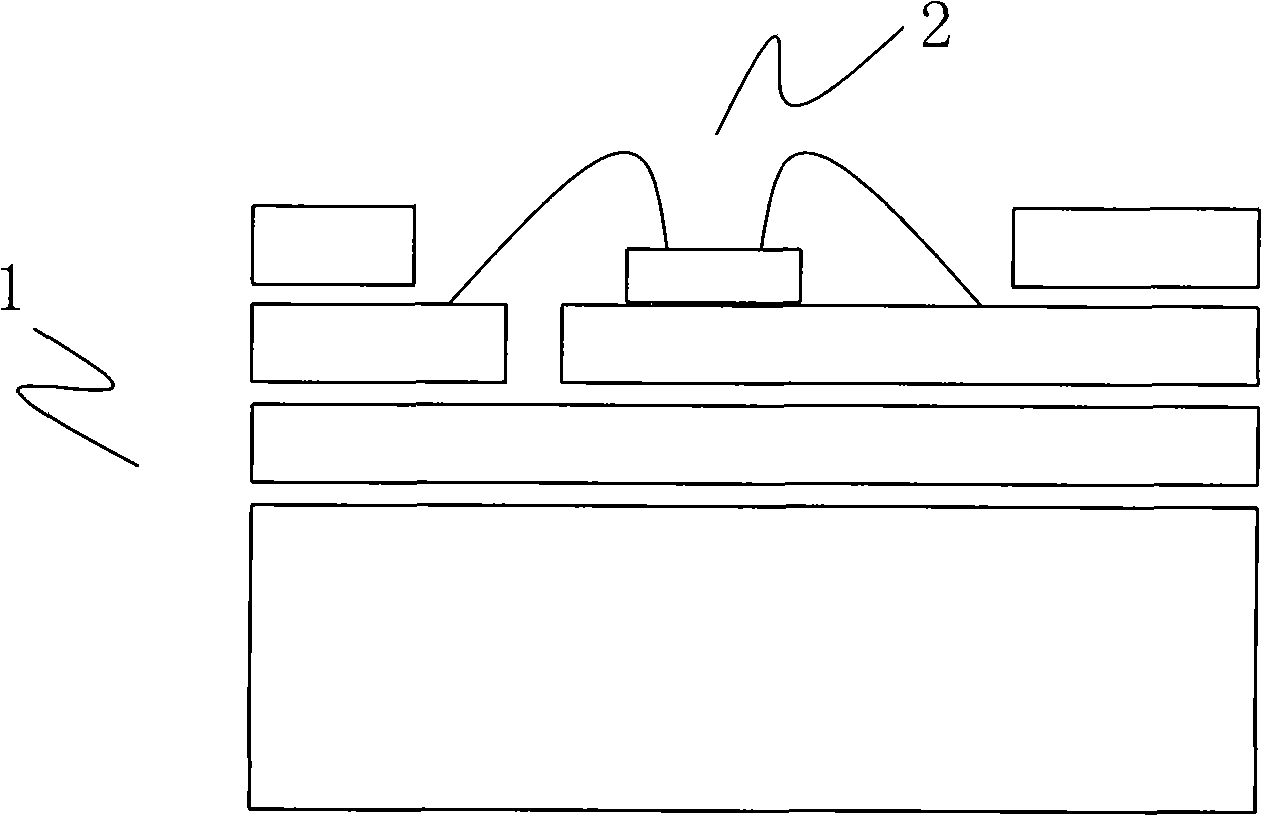

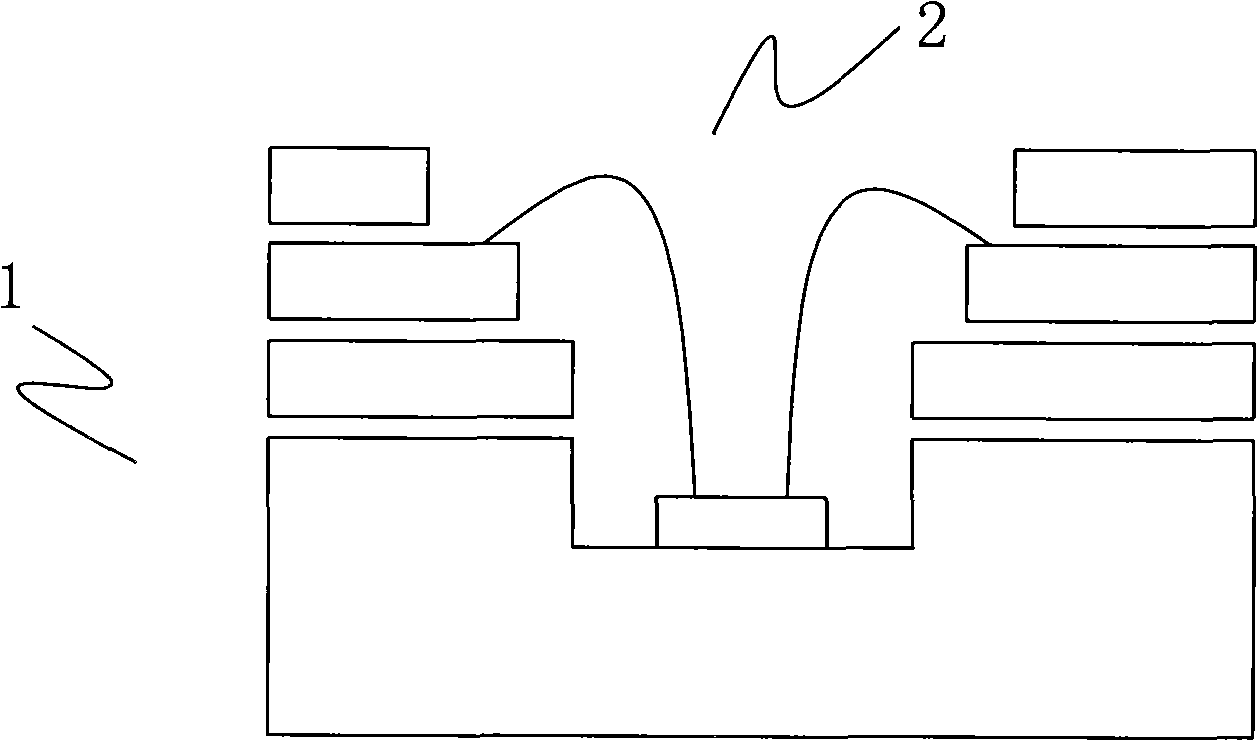

Light emitting diode base plate heat radiation structure and manufacture method thereof

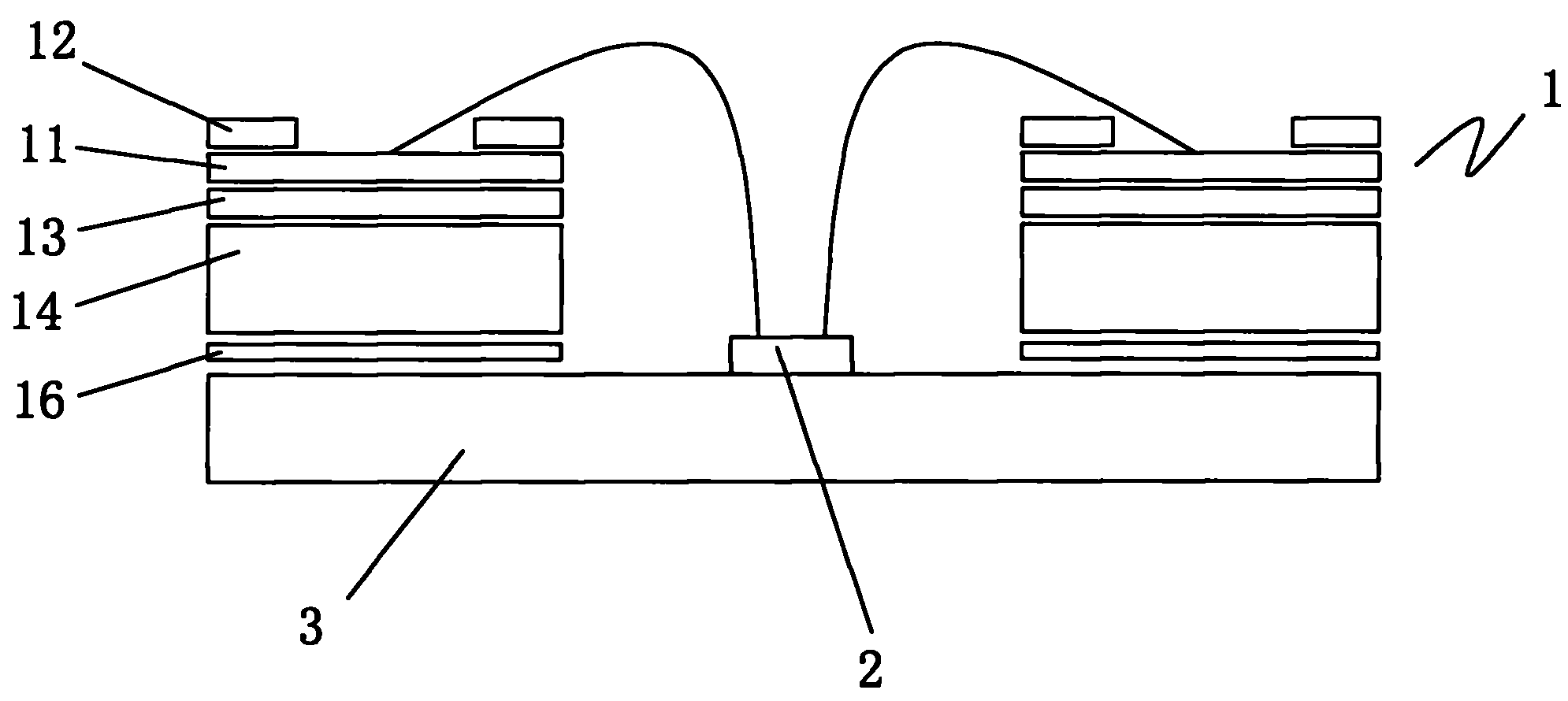

InactiveCN101814574ADoes not affect the manufacturing processEasily lostSolid-state devicesSemiconductor devicesLight-emitting diodeHigh heat

The invention relates to a light emitting diode circuit board heat radiation structure, which comprises a circuit board and a light emitting diode, wherein the light emitting diode is communicated with a circuit of a conductive circuit layer in the circuit board, a heat radiation bottom plate is tightly pasted on the lower surface of the circuit board, a through hole is formed in the position of the circuit board provided with the light emitting diode, and the light emitting diode is pasted on the inner surface of the bottom plate through the through hole. Through the additional arrangement of the heat conductive plate, the structure eliminates the adverse influence caused by self damage of the circuit board and the subsequent manufacture and processing in the prior art, and the light emitting diode can be directly pasted on the heat radiation bottom plate, so the whole base plate has higher heat conduction coefficient, the light ray emitting effect and the heat radiation effect are good, in addition, the manufacture and processing process of the existing circuit board can not be influenced, the bottom plate can be singly processed, the smoothness and the finish degree of the bottom plate can be easily ensured, the processing step is greatly simplified, and the manufacture difficulty is reduced, so the production cost is reduced.

Owner:FORYOU MULTIMEDIA ELECTRONICS

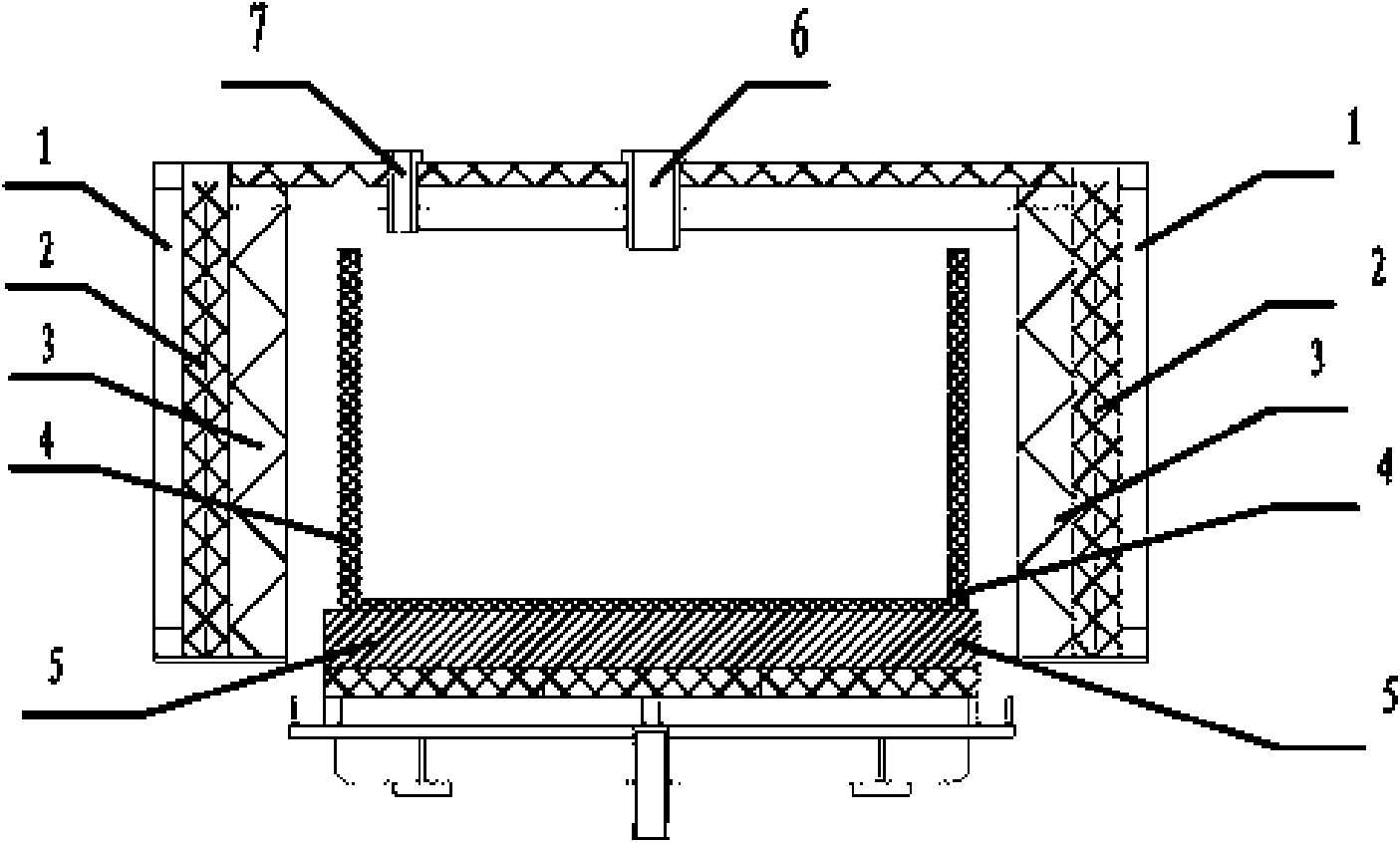

Insulation system for polycrystalline silicon ingot furnace

InactiveCN101660201AImprove heat stabilityHigh thermal efficiencyPolycrystalline material growthSilicon compoundsFiberMetal framework

The invention relates to an insulation system for a polycrystalline silicon ingot, comprising a furnace body. A metal frame is arranged on the periphery inside the furnace body; the lateral wall of the metal frame is provided with a lateral mullite fiber board; the top part of the metal frame is provided with a top mullite fiber board; the bottom of a graphite plate under a crucible is provided with a bottom mullite fiber plate; a closed space is formed by the mullite fiber plates which are positioned on the bottom of the graphite plate, in the lateral wall of the metal frame and on the top ofthe metal frame respectively; a layer of a corundum mullite burning plate is arranged inside of the lateral mullite fiber plate close to the center of the furnace center. The insulation system can reduce electric energy consumption in a process for casting the polycrystalline silicon, reduces thermal stress of the silicon ingot and improves yield of slices when large silicon ingots are cast, andis particularly suitable for producing polycrystalline silicon ingots over 450kgs.

Owner:NAN AN SANJING SOLAR POWER

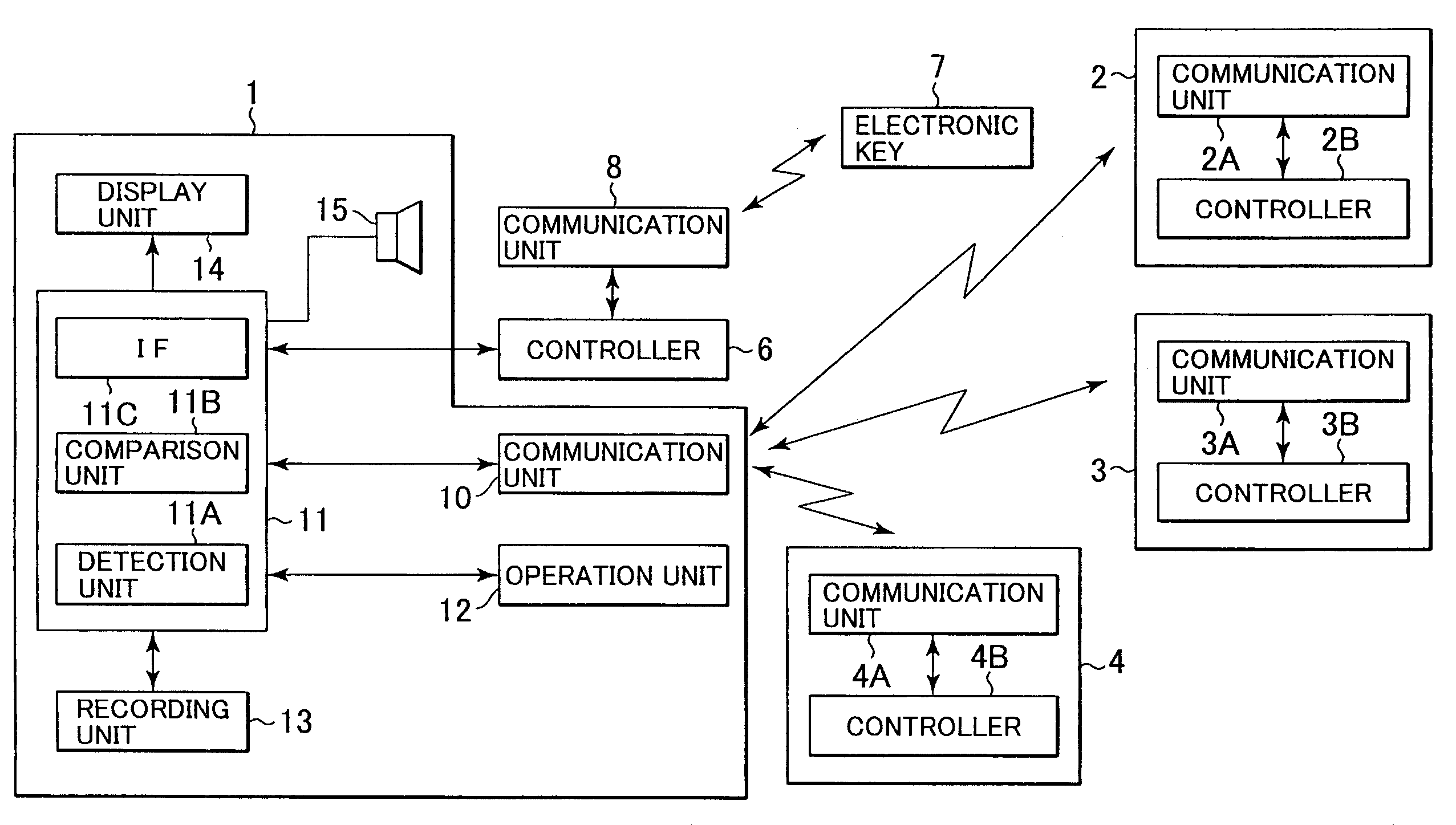

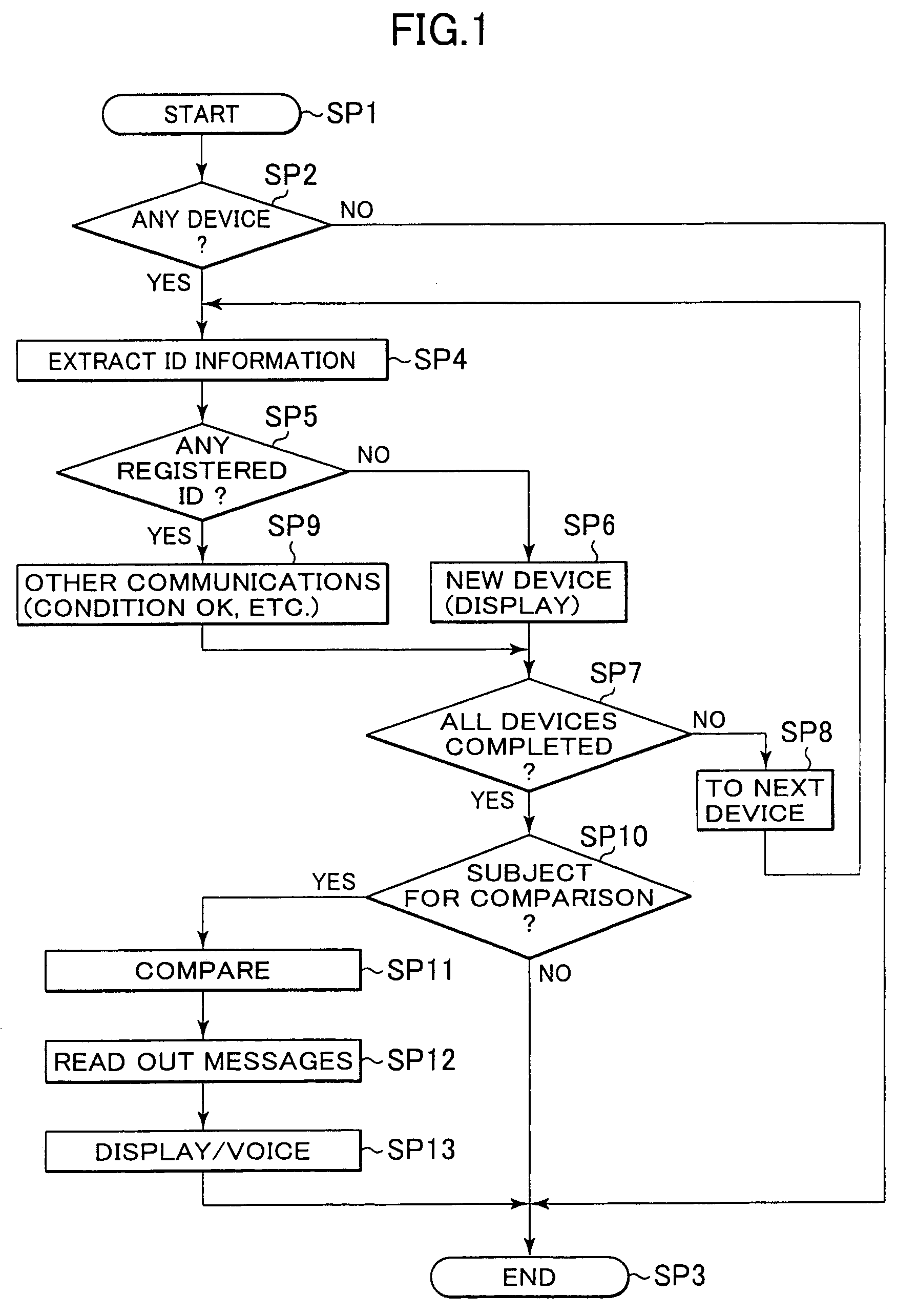

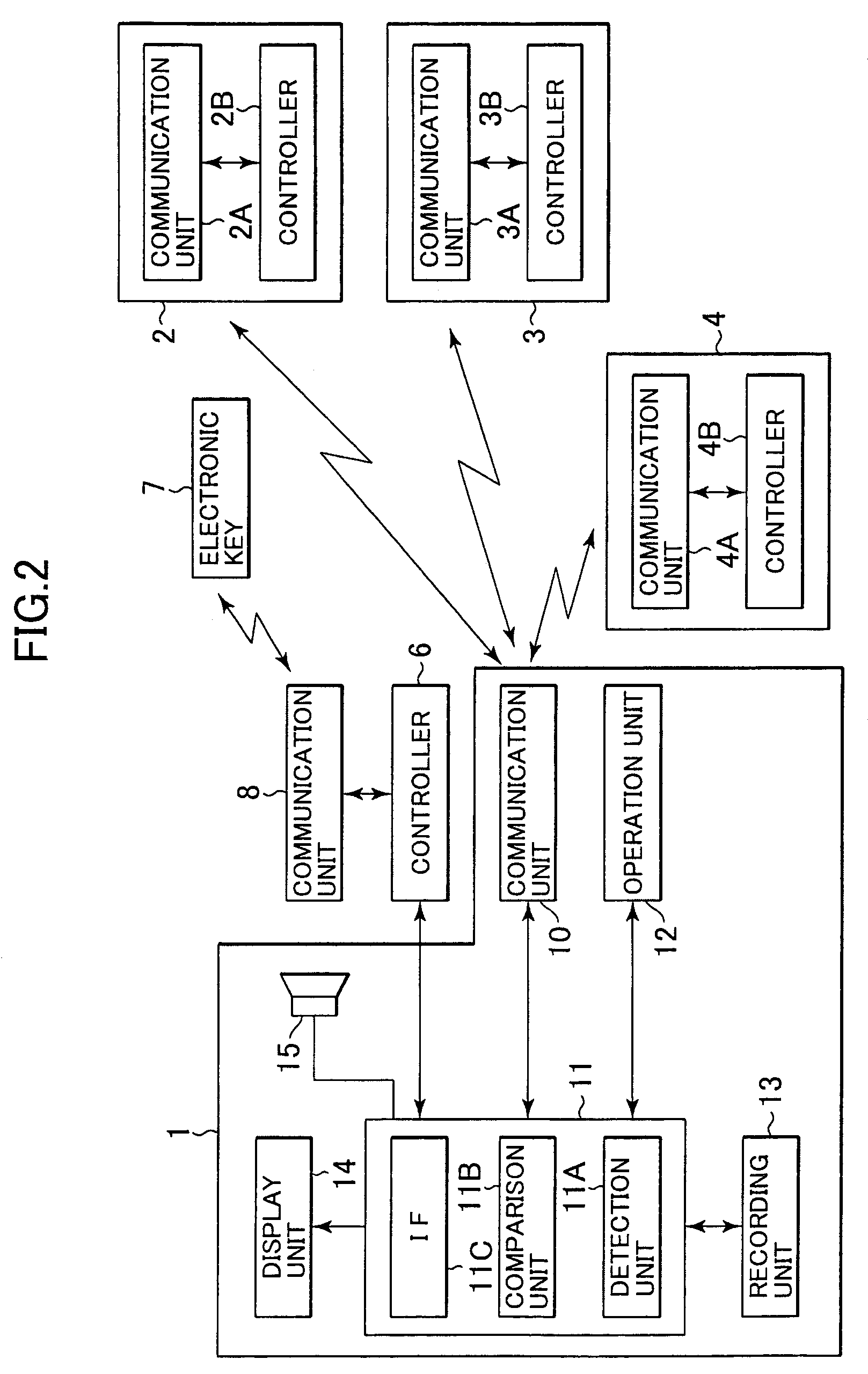

Property management apparatus, property management method, and property management system

ActiveUS7230536B2Easily lostEasily preventingProgramme controlElectric signal transmission systemsEngineeringManagement system

In the present invention, any change of devices in possession by a user who gets on or gets off, for example, a vehicle is detected by comparing the devices detected by wireless communication at the time of getting on or getting off, thereby enabling the easy and sure prevention of any personal belongings of the passenger from being lost or left without constantly monitoring them. The property management apparatus sums up in time series the detection results by the plurality of property detection apparatuses for notifying the user the place of where the user loses the property.

Owner:SONY CORP

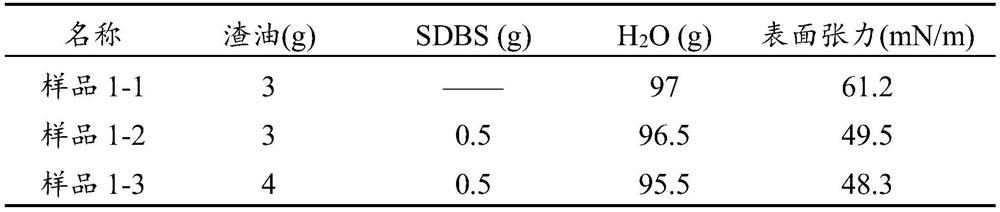

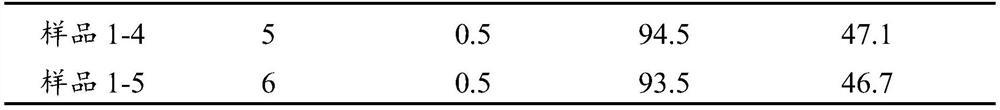

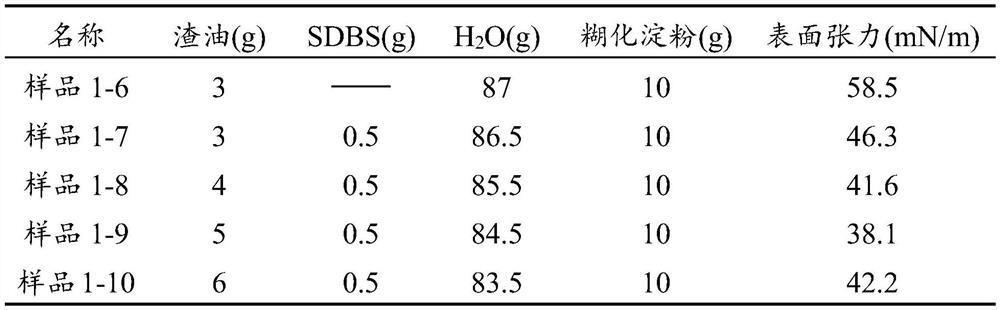

Composite dust suppressant as well as preparation method and application thereof

ActiveCN113512405AIncrease stickinessGood evaporation resistanceOther chemical processesDust removalPhysical chemistryEnvironmental engineering

The invention relates to the technical field of dust suppressants, and provides a composite dust suppressant. According to the composite dust suppressant provided by the invention, the evaporation resistance of the composite dust suppressant is improved by adding the residual oil, the gelatinized starch and the non-cationic water-soluble polymer; through multiple cooperation of the strong electrolyte, the non-cationic water-soluble polymer, the non-cationic surface active agent and the chelating agent, the surface tension of the dust suppressant is reduced to about half of that of water, so that the dust suppressant has excellent wettability to dust; by adding halide, the freezing resistance of the dust suppressant is improved, and the dust suppressant cannot be frozen at the temperature of -26.6 DEG C to-20.3 DEG C. The composite dust suppressant obtained by the invention has a good dust suppression effect, and can effectively reduce the dust concentration in the open pit coal mine.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

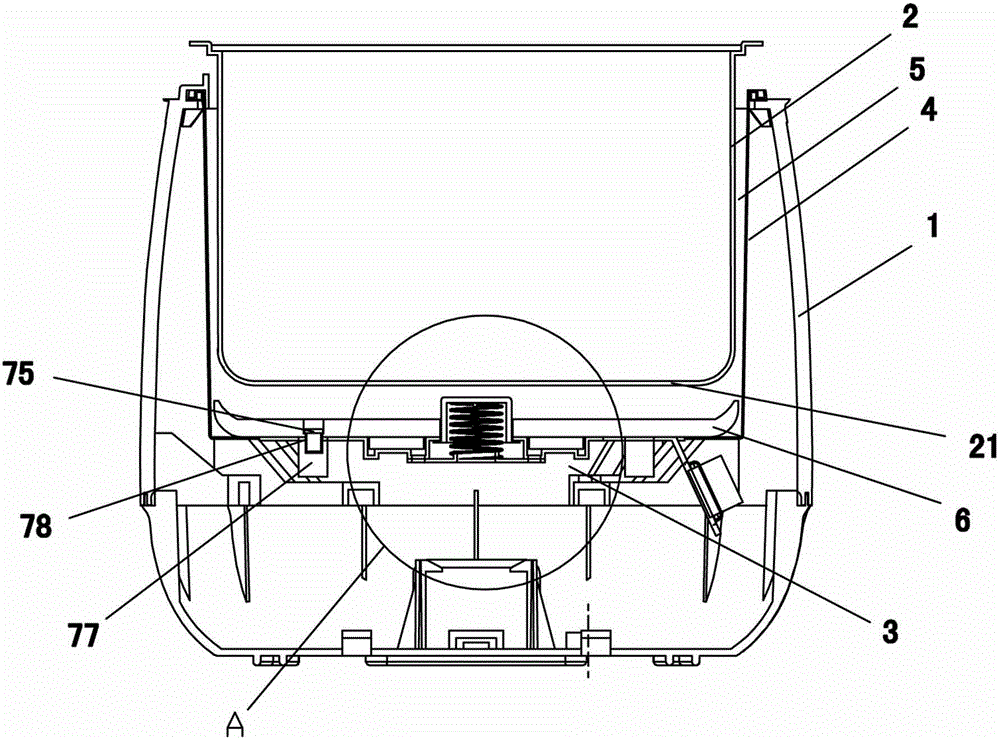

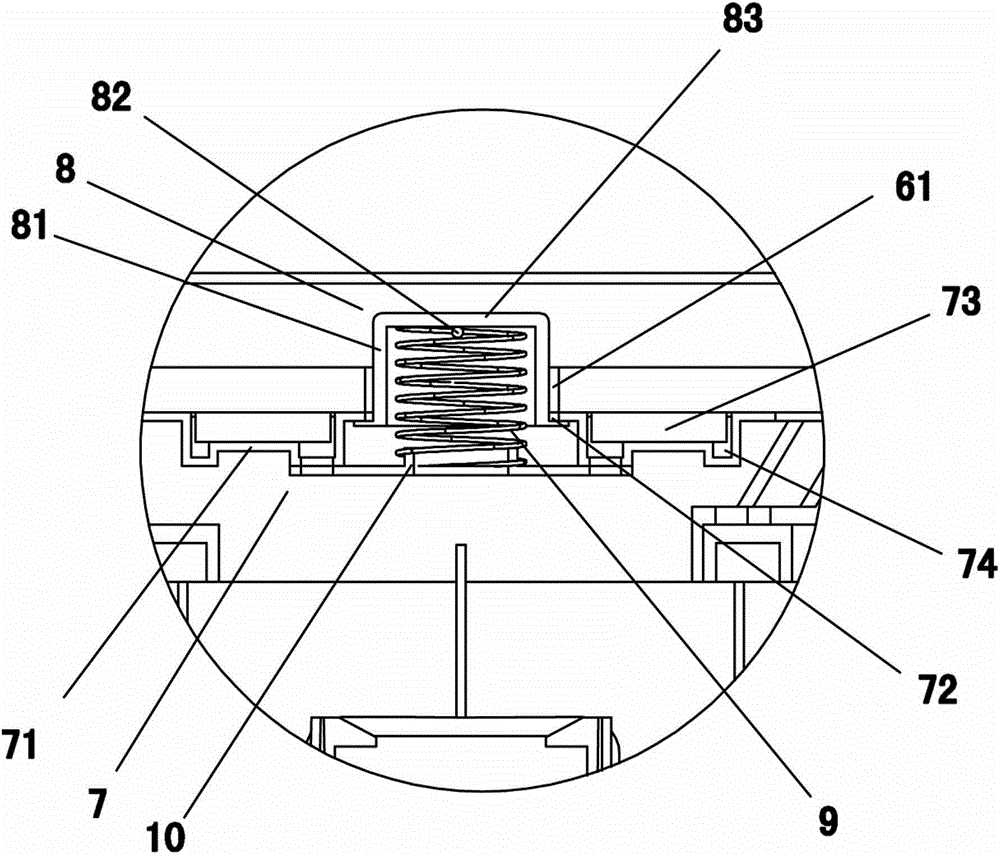

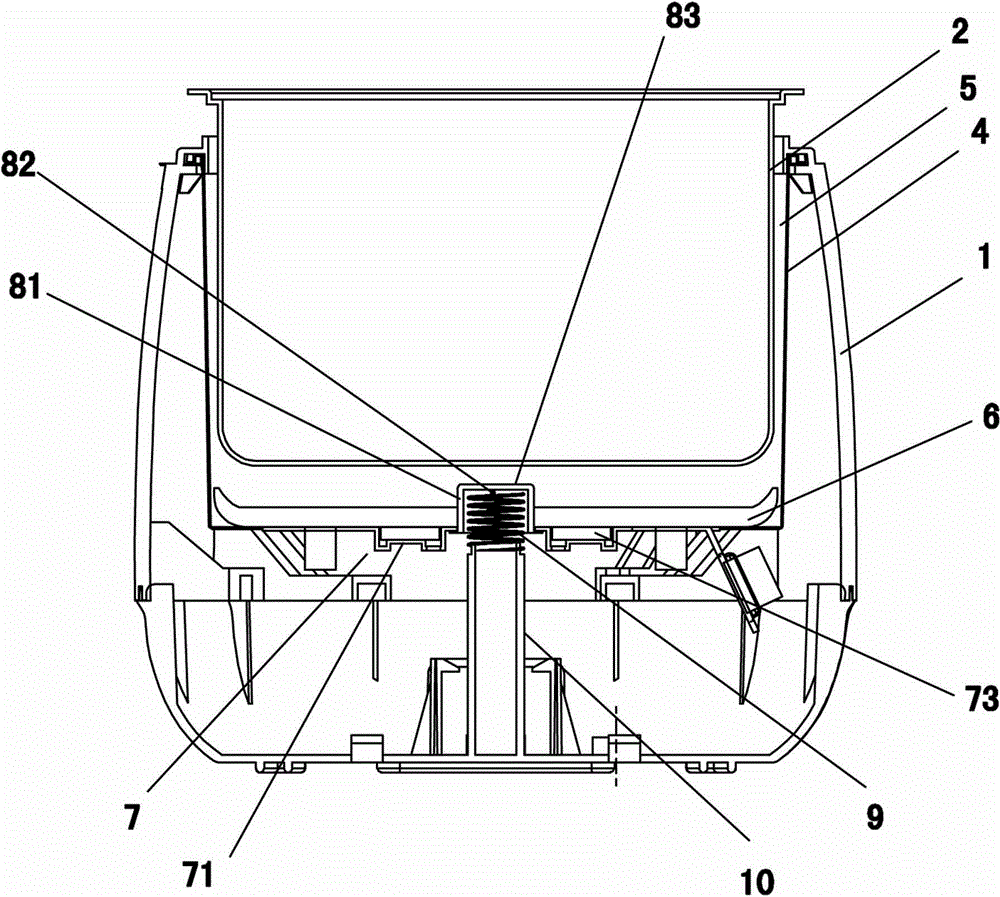

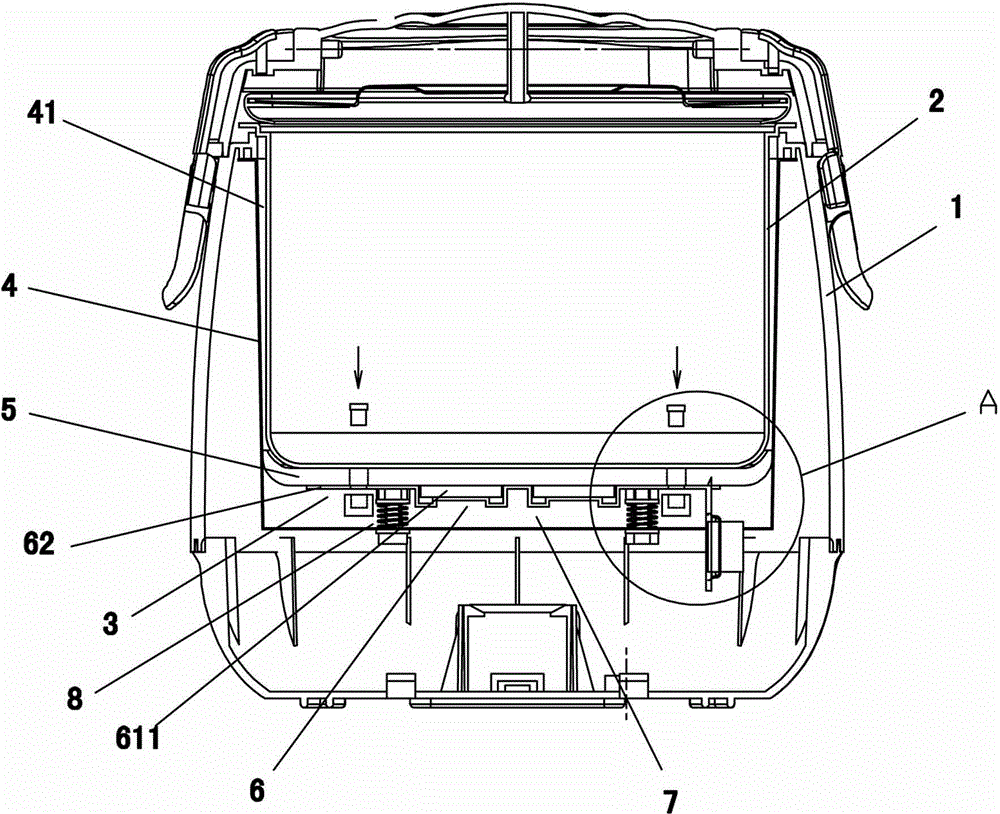

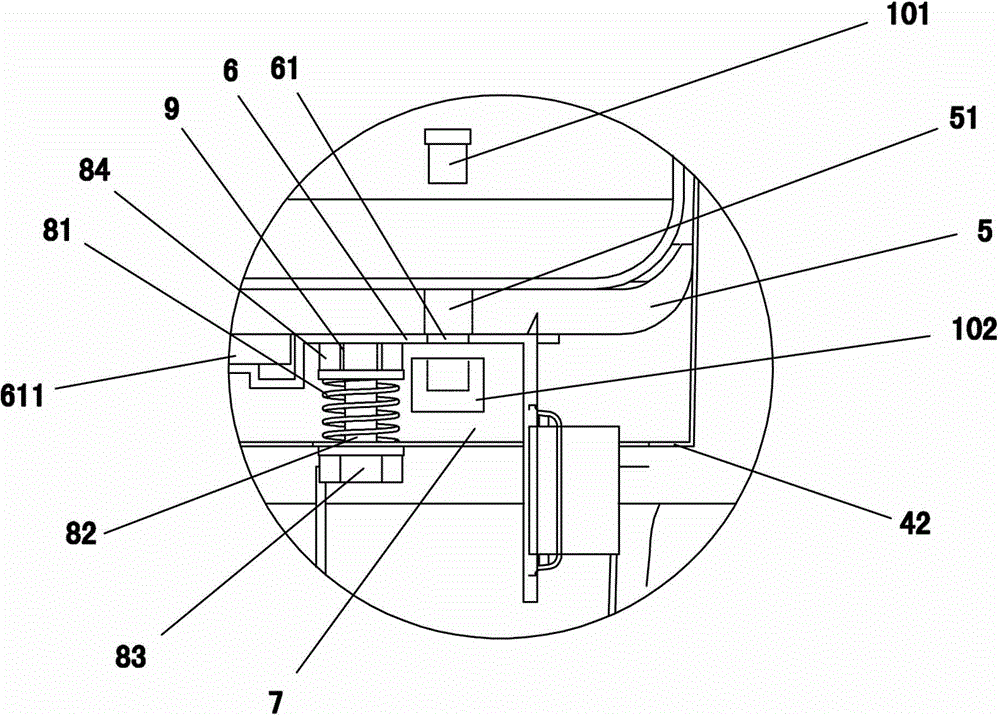

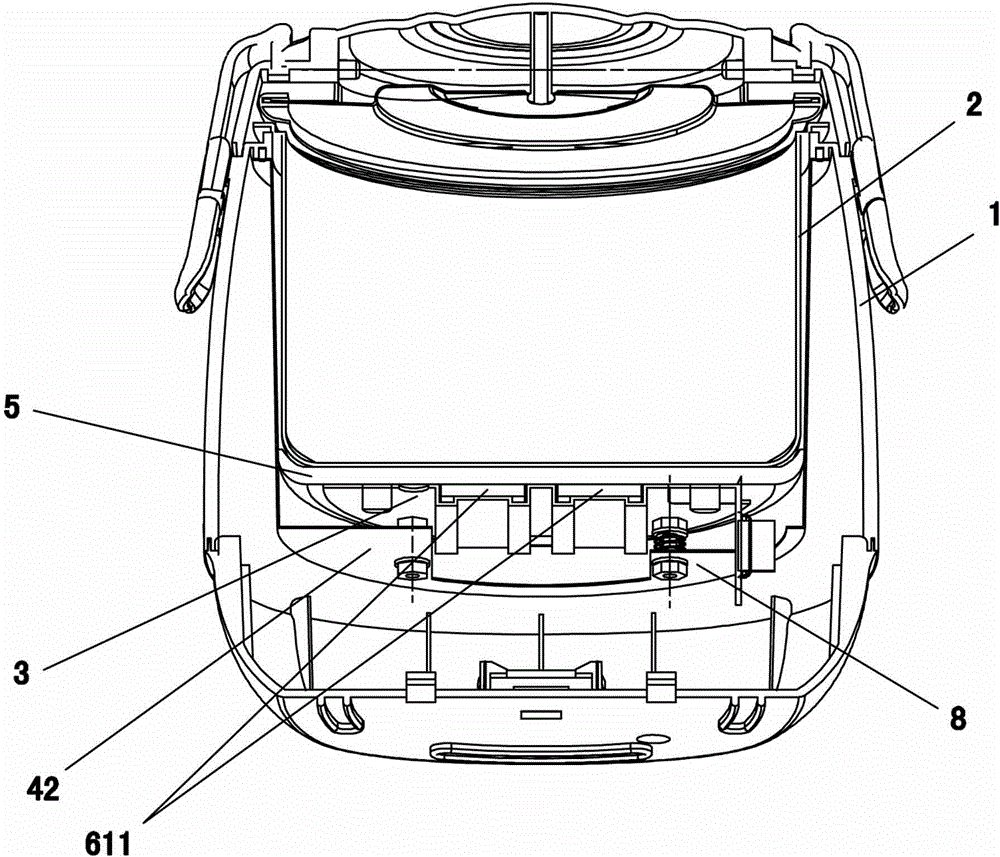

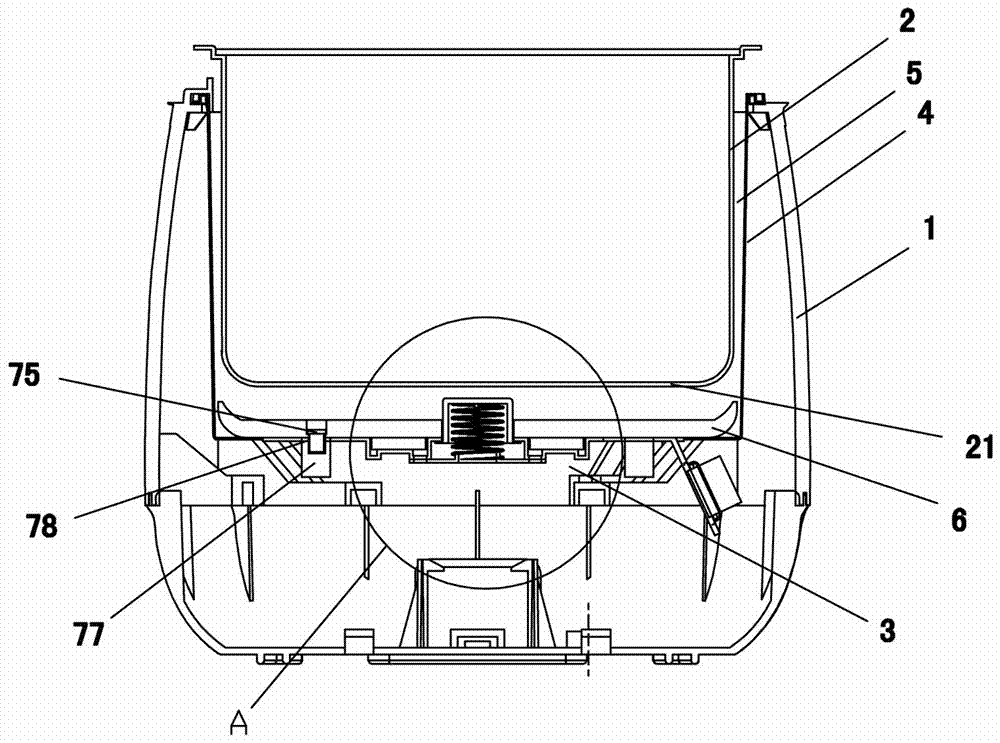

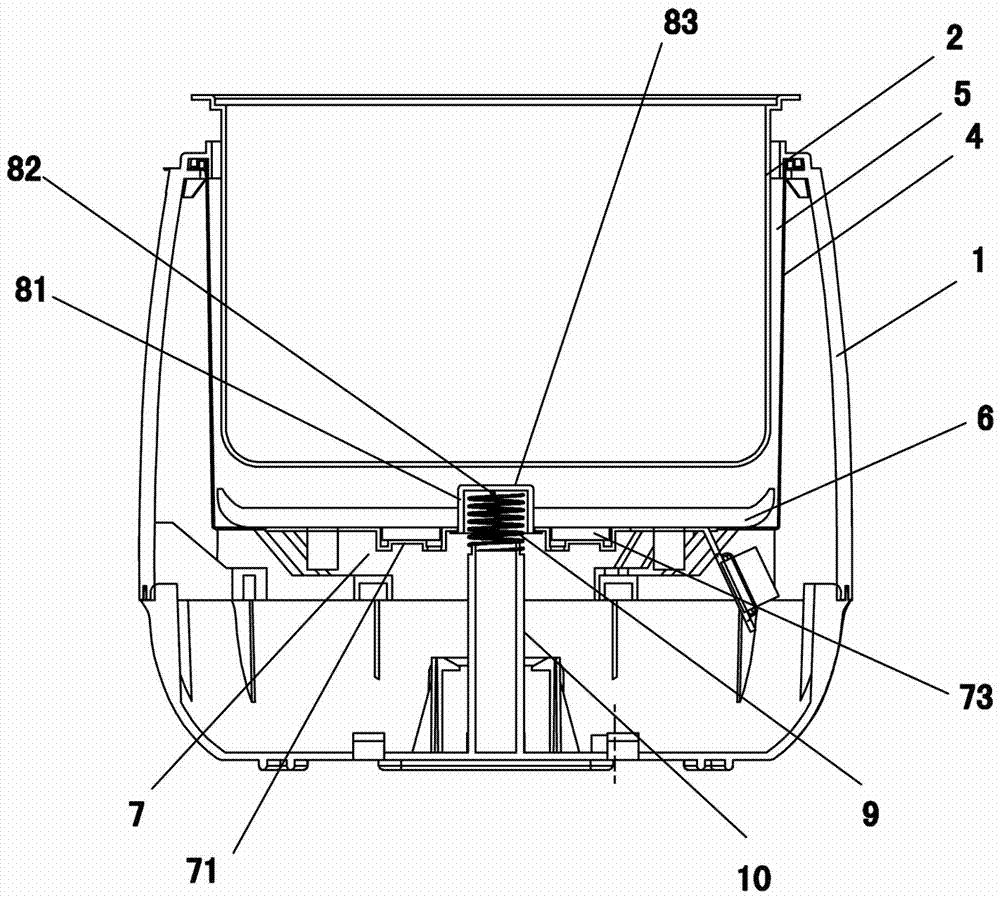

Temperature-sensing element mounting structure for miniature electric rice cooker

ActiveCN104887059APrevent heat from being easily lostEvenly heatedWarming devicesElectric heatingCooker

The invention relates to a temperature-sensing element mounting structure for a miniature electric rice cooker. The temperature-sensing element mounting structure comprises an outer pot, an inner container and an electric heating device, a middle layer is arranged inside the outer pot, an inner cavity is formed in the middle layer, the electric heating device is arranged on the lower portion of the inner cavity of the middle layer and comprises a heat conducting tray and an electric heating body, and the electric heating body is connected at the bottom of the heat conducting tray. The temperature-sensing element mounting structure is characterized by further comprising a temperature-sensing element and an elastic part thereof, and the temperature-sensing element is arranged below the bottom wall of the inner container through the elastic part and elastically contacts with the bottom wall of the inner container. The temperature-sensing element mounting structure for the miniature electric rice cooker has the advantages that the structure is simple and reasonable, the temperature-sensing element is easily mounted and replaced, temperature data of the inner container can be transmitted in real time, multifunctional and intelligent control is realized, the inner container is uniformly heated, heat is not easily lost, heat efficiency is obviously improved and the like.

Owner:GUANGDONGEUROS AUTO SUPPLIES

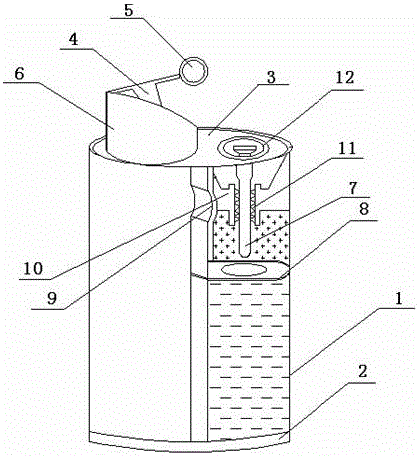

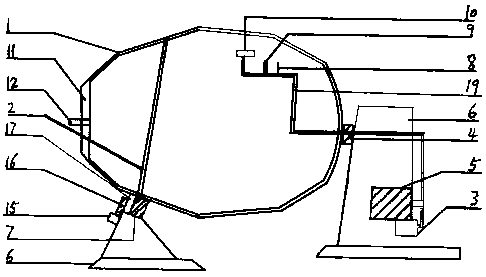

Self-refrigerating or self-heating ring-pull can

InactiveCN105857947AImprove securityImprove sealingContainers for heating foodPackaging foodstuffsMechanical engineeringMaterials science

The invention provides a self-refrigerating or self-heating ring-pull can. The self-refrigerating or self-heating ring-pull can comprises a can body, a sealing cover, a base and a partition layer. A protruding beverage opening is formed in the sealing cover. A sealing piece and a pull ring are mounted on the beverage opening. The sealing piece is connected with the beverage opening in a press-fit manner. The outer ring of the pull ring is fixedly connected with the extension portion of the sealing piece. The partition layer is located in an inner cavity of the ring-pull can and partitions the cavity into two parts. The left cavity body is used for containing beverages or food. The right cavity body is a reaction chamber. A baffle is arranged in the middle of the reaction chamber. The upper portion of the reaction chamber is a powder chamber, and the lower portion of the reaction chamber is a liquid chamber. A reaction trigger device is arranged on the powder chamber and comprises a stress gun and a stabilizing wall. The stabilizing wall is connected with the can body and the partition layer in a non-detachable manner. The portion, connected with the stabilizing wall, of the partition layer is provided with a circular-arc-shaped fixing groove. The self-refrigerating or self-heating ring-pull can is easy to design, easy to operate and convenient to apply and popularize.

Owner:范道柱

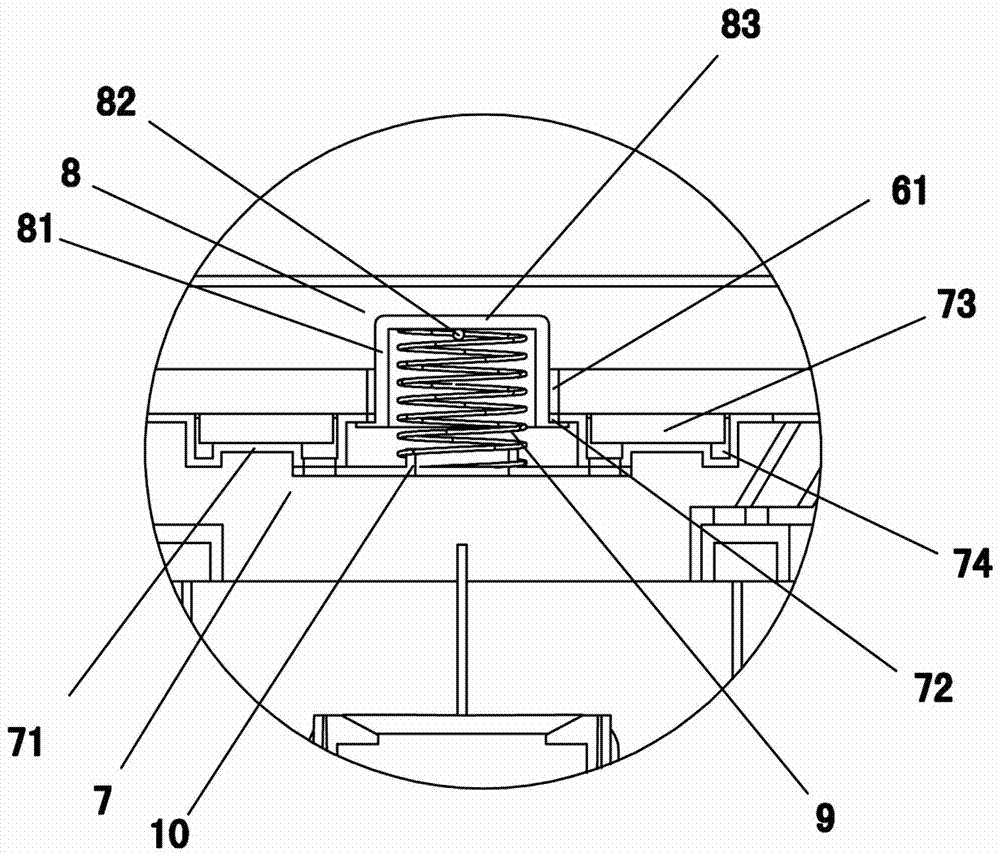

Elastic heating body mounting structure for miniature electric rice cooker

InactiveCN104887093APrevent heat from being easily lostEvenly heatedWarming devicesCookerElectric heating

The invention relates to an elastic heating body mounting structure for a miniature electric rice cooker. The elastic heating body mounting structure comprises an outer pot, an inner container and an electric heating device. The elastic heating body mounting structure is characterized in that a middle layer is arranged inside the outer pot, an inner cavity is formed in the middle layer, the electric heating device is arranged on the lower portion of the inner cavity of the middle layer and comprises a heat conducting tray and an electric heating body, the electric heating body is connected at the bottom of the heat conducting tray, a gap is reserved between the electric heating device and the bottom wall of the inner cavity of the middle layer, an elastic part is arranged between the electric heating device and the bottom wall of the inner cavity of the middle layer, the electric heating device is seated on the elastic part, and the inner container is arranged in the inner cavity of the middle layer and elastically contacts with the heat conducting tray of the electric heating device. The elastic heating body mounting structure for the miniature electric rice cooker has the advantages that the structure is simple and reasonable, the inner container is separated from the heating device, can be independently taken out and used and is uniformly heated, heat is not easily lost, heat efficiency is obviously improved and the like.

Owner:何志雄

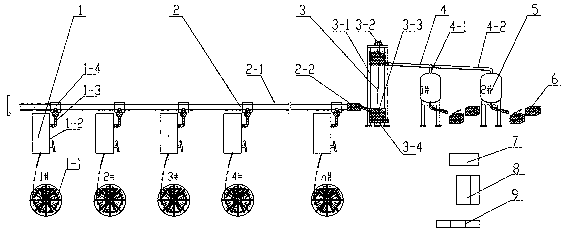

A method of preparing natural hawthorn fruit powder roasted in vacuum at a low temperature and a device thereof

A method of preparing natural hawthorn fruit powder roasted in vacuum at a low temperature and a device thereof are provided. The hawthorn fruit powder prepared by the method integrates medicinal and edible functions of hawthorn fruit, original fragrance of the hawthorn fruit can be maintained, contents of coarse fibers and water are low, sterilization is thorough, shelf life is long, and the hawthorn fruit powder is a purely-natural green healthcare food free of additives. The method includes cleaning the hawthorn fruit, soaking the hawthorn fruit, dewatering, pitting, roasting, stacking, sterilizing hawthorn fruit powder, and sub-packing hawthorn fruit powder ground by a crushing machine into bags according to needs. The hawthorn fruit powder prepared by the method maintains original nutrients and flavor of hawthorn fruit, and a plurality of new nutrients are generated. The hawthorn fruit powder has fine particles and good reconstitution performance, can be brewed with boiling water into hawthorn pulp and drunk, and also can be used as an auxiliary material for foods and beverages.

Owner:周忠新

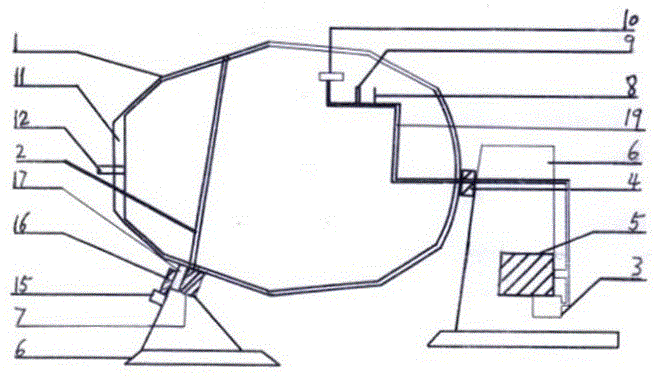

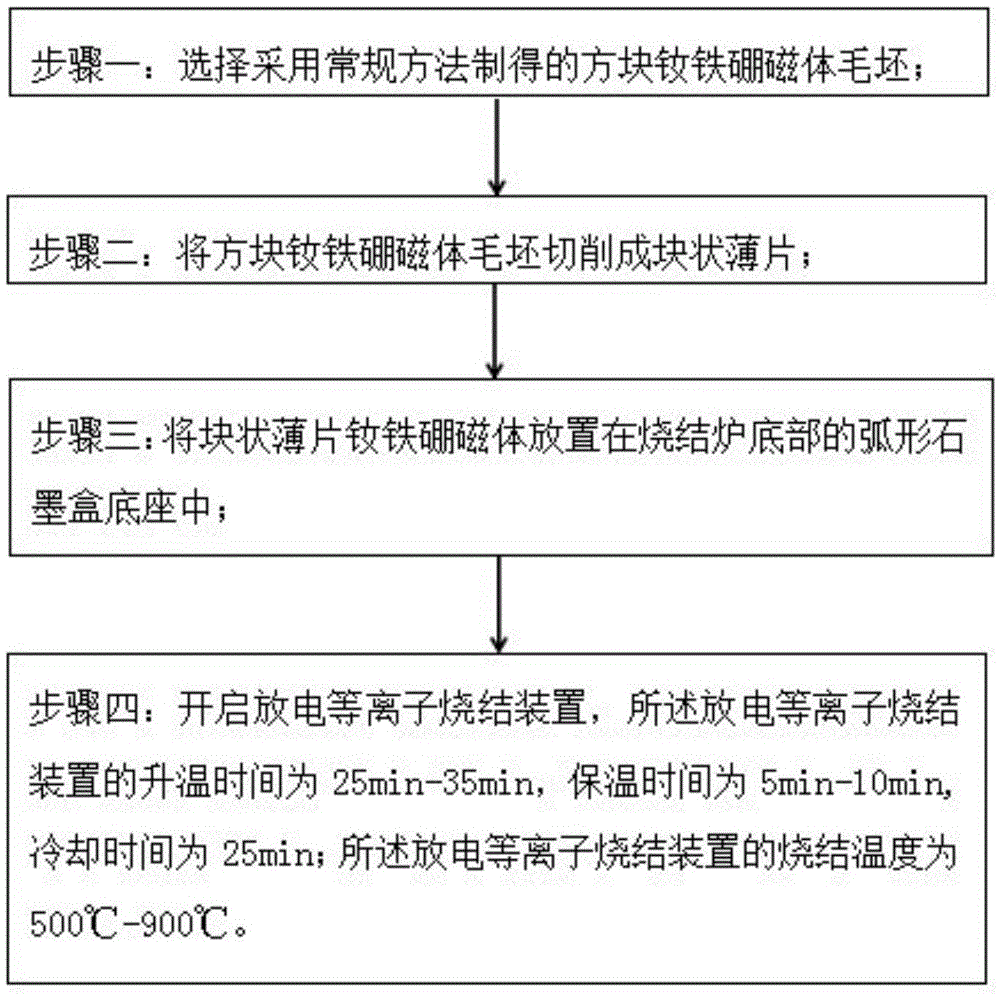

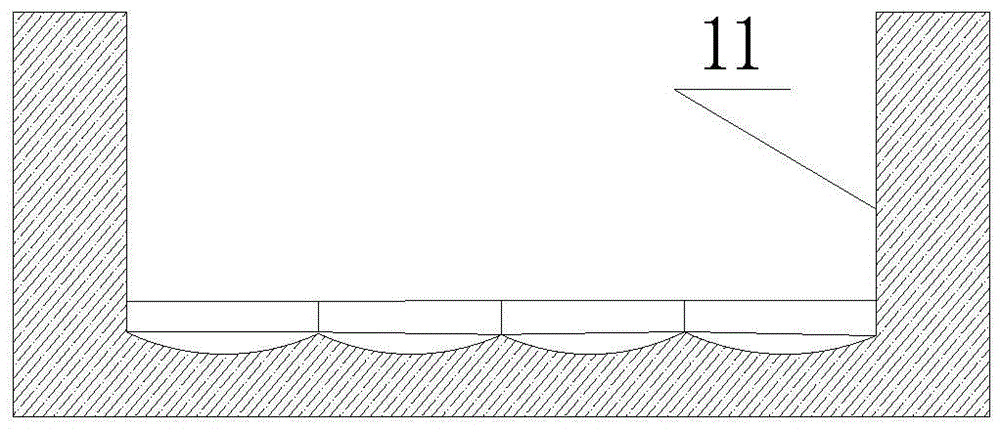

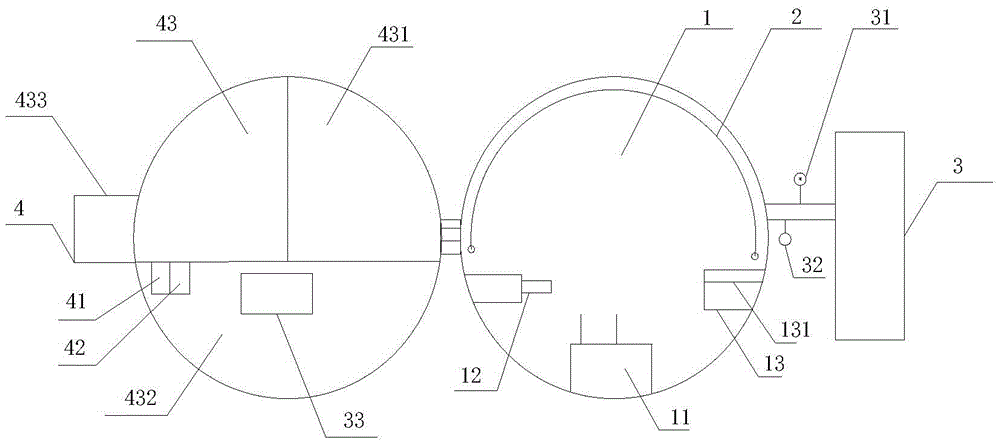

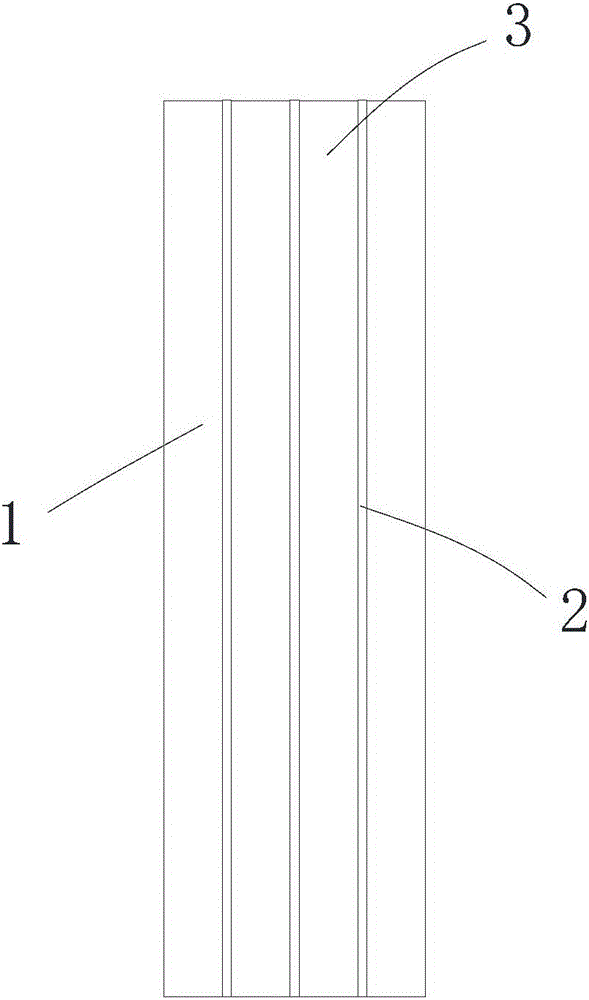

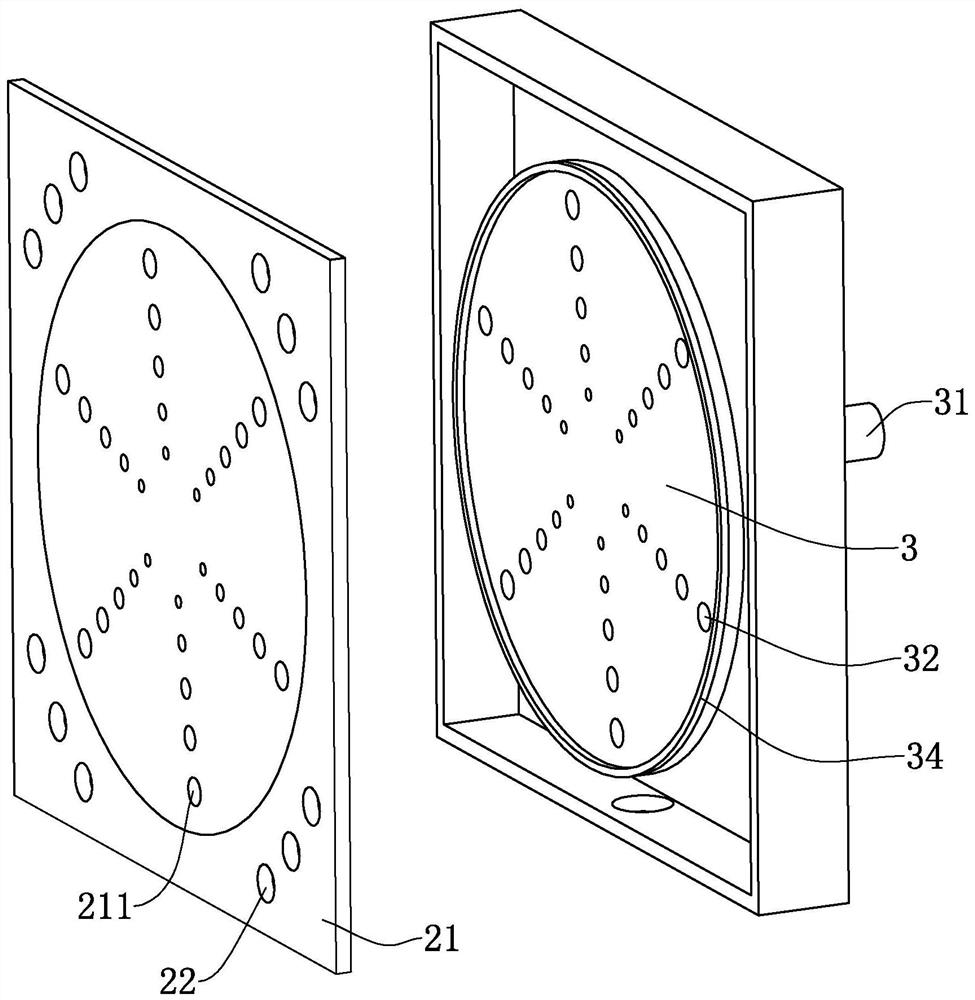

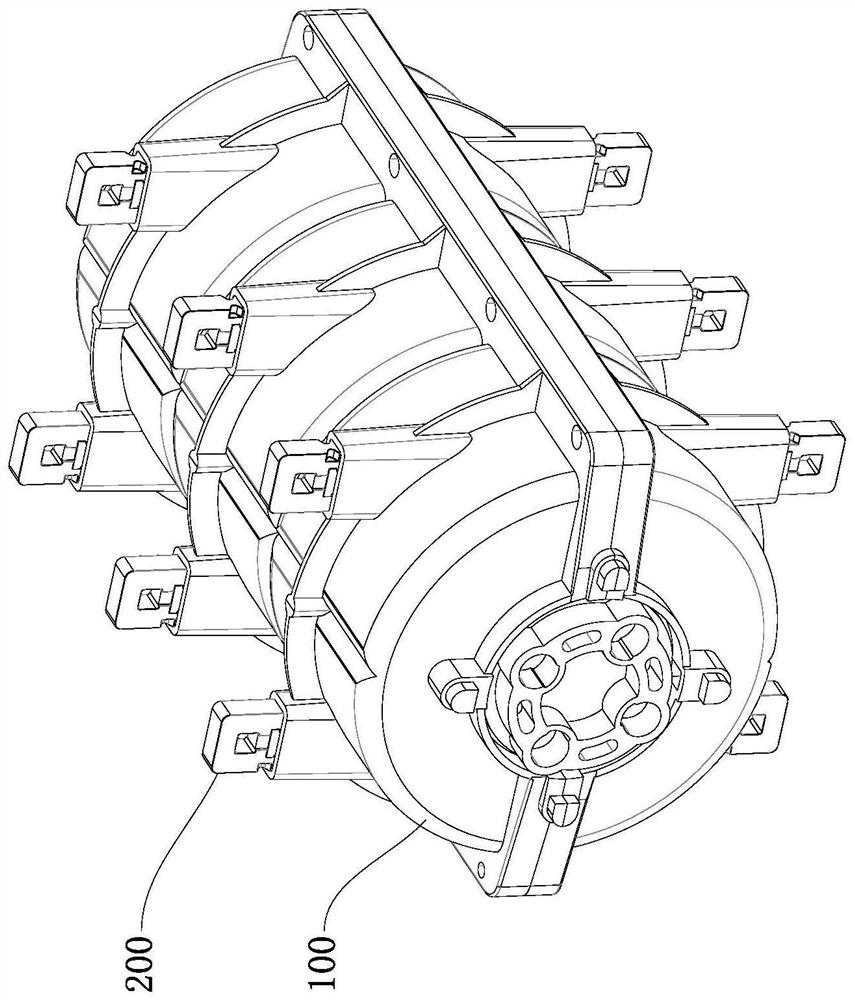

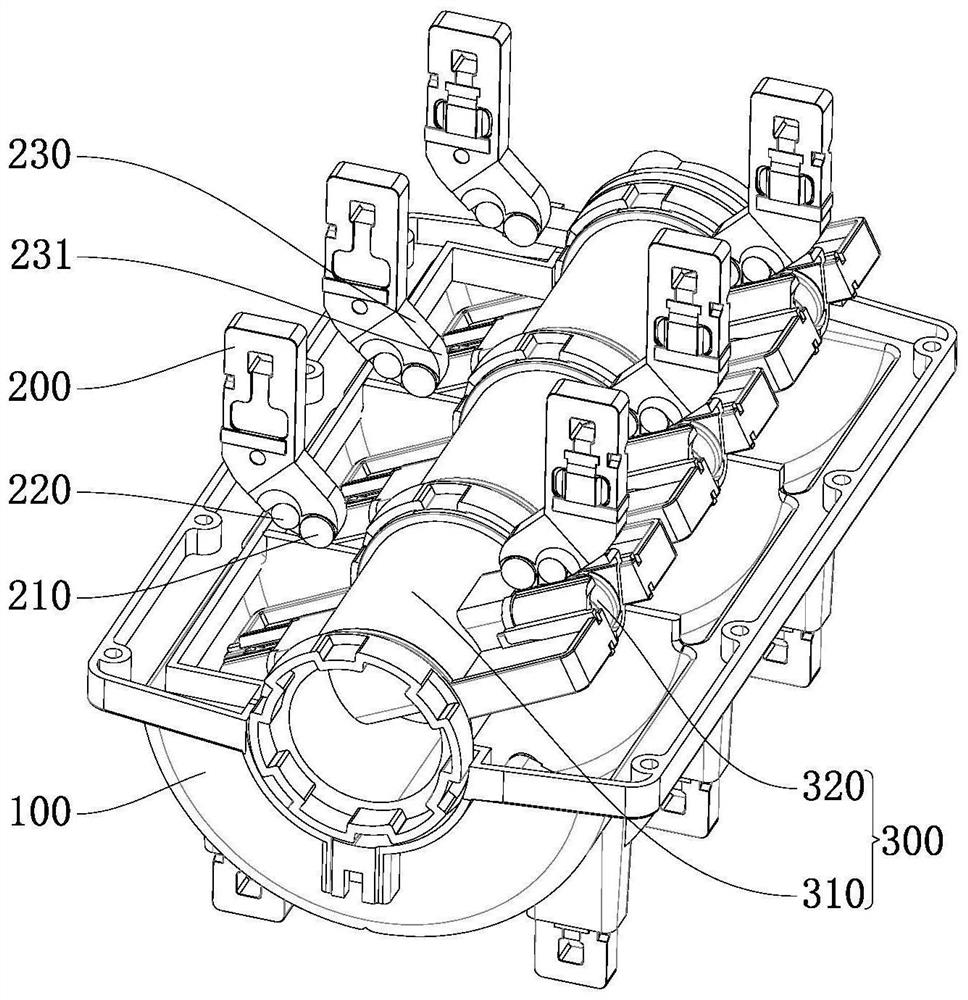

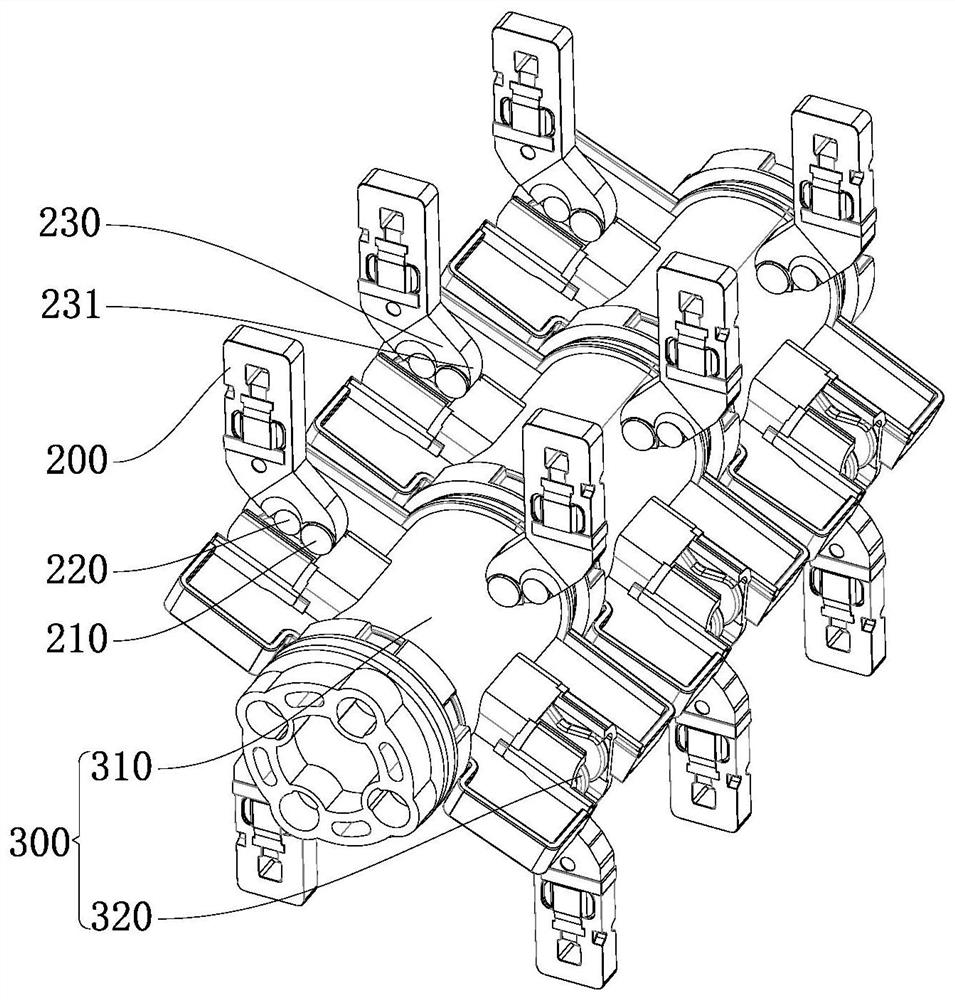

Method for sintering neodymium iron boron magnetic tile and spark plasma sintering device thereof

ActiveCN105632674AGood orientationIncrease intensityInorganic material magnetismManufacturing dynamo-electric machinesControl systemHearth

The invention provides a method for sintering a neodymium iron boron magnetic tile. The method comprises the following steps of 1, selecting a square neodymium iron boron magnet blank prepared by a conventional method; 2, cutting the square neodymium iron boron magnet blank into block-shaped thin sheets; 3, placing the block-shaped thin sheet neodymium iron boron magnet in an arc graphite box base at the bottom of a sintering furnace in a radial distribution mode; and 4, starting a spark plasma sintering device, and carrying out sintering, heat preservation and cooling. The spark plasma sintering device used for the method for sintering the neodymium iron boron magnetic tile comprises a hearth, a dual-layer liquid cooling device, an atmosphere control system and a heat preservation system, wherein the dual-layer liquid cooling device, the atmosphere control system and the heat preservation system are respectively and fixedly connected with the hearth, the dual-layer liquid cooling device comprises a slow-action liquid cooling outer layer and a high-speed liquid cooling inner layer, and the slow-action liquid cooling outer layer and the high-speed liquid cooling inner layer are fixedly connected. The magnetic tile prepared according to the method is large in magnetic dynamics and high in strength, and moreover, the magnetic tile is low in energy consumption during the fabrication process and high in efficiency.

Owner:JIANGSU PULONG MAGNETIC ELECTRICITY CO LTD

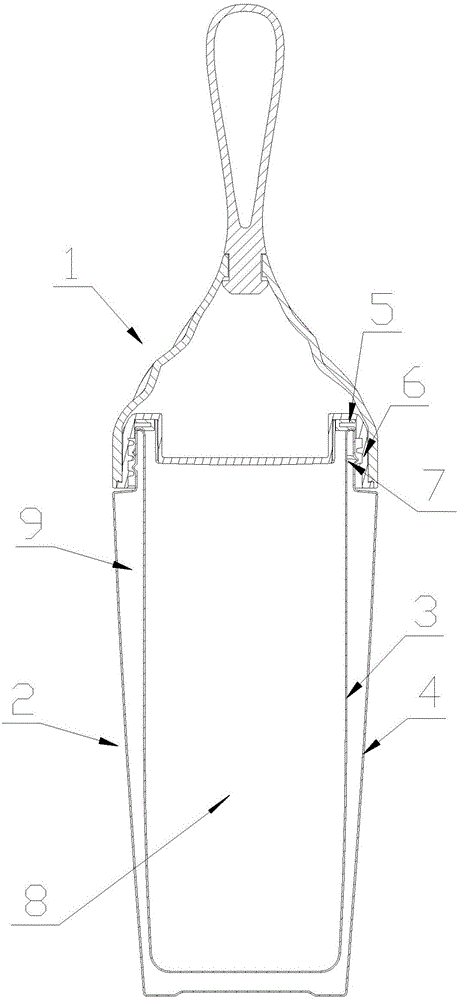

Aerogel vacuum cup

InactiveCN106579963AGood heat insulationGood insulationDrinking vesselsThermal insulationEngineering

The invention discloses an aerogel vacuum cup, comprising a cup cover and a cup body. The cup body comprises an inner layer and a housing, and a sealed aerogel layer between the inner layer and the housing. The cup cover forms a closed water storage thermal insulation space on the upper end open position of the cup body. The cup cover is internally provided with a seal ring. The rim of the cup body is provided with external threads. The inner side of the cup cover is provided with internal threads. The cup cover is screwed on the external threads of the cup body through the internal threads, to form an airtight space. The cup has certain thermal insulation effect, and meanwhile heat is easy to lose, and the cup can effectively prevent a user from being scalded in use.

Owner:ZHEJIANG GINT VACUUM FLASK TECH CD LTD

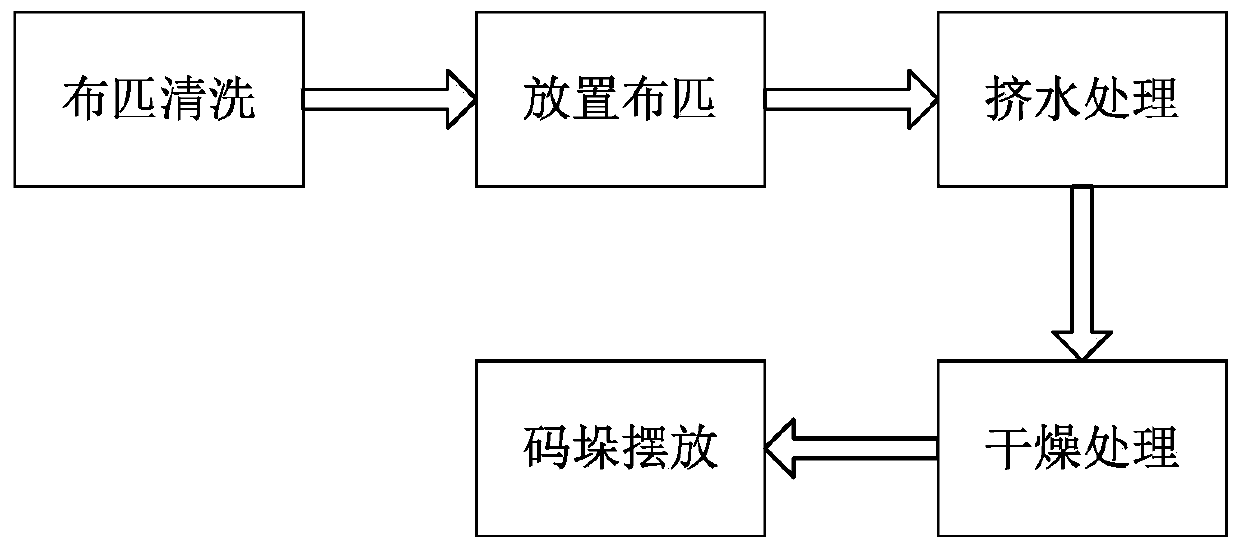

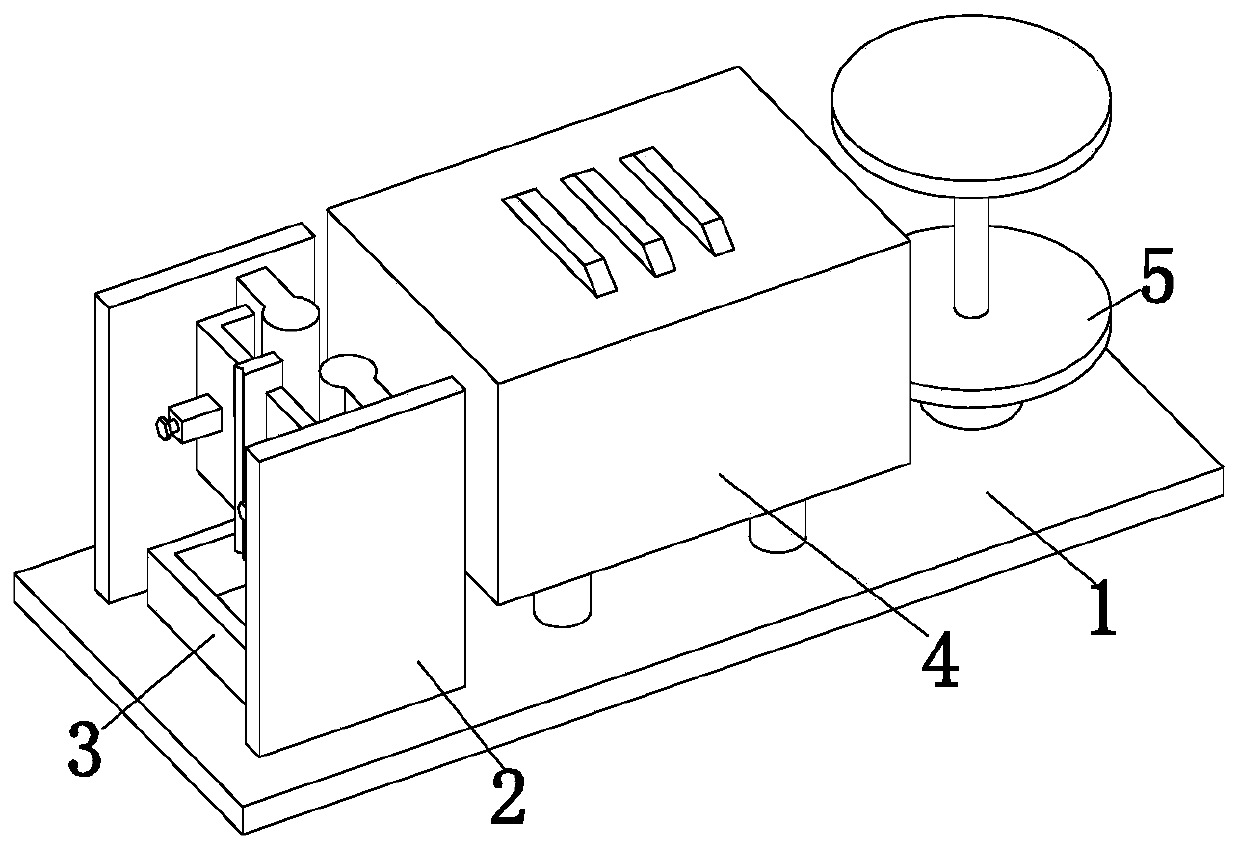

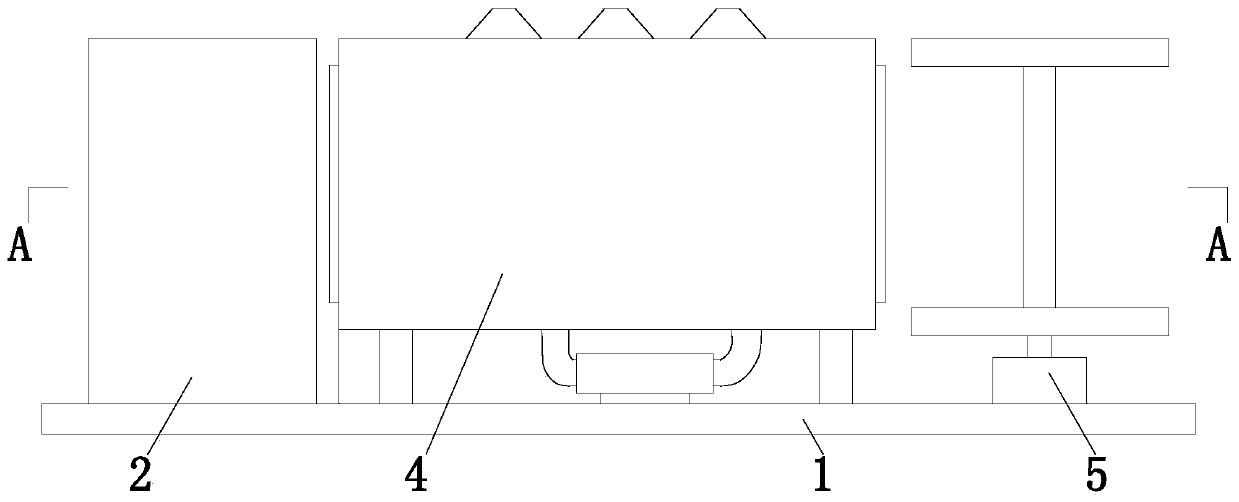

Textile cloth after-treatment process

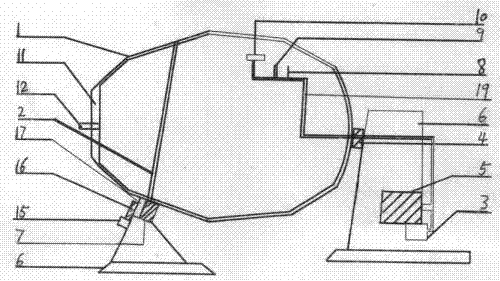

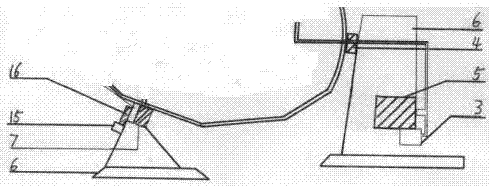

InactiveCN111350042AReduce drying efficiencyReduced aestheticsDrying solid materials with heatDrying solid materials without heatEngineeringMechanical engineering

The invention relates to a textile cloth after-treatment process. The textile cloth after-treatment process comprises a bottom plate, a water squeezing device, a water collecting tank, a drying deviceand a traction device; the water squeezing device is installed at the upper end of the bottom plate; the water collecting groove is arranged below the water squeezing device; the water collecting groove is installed on the bottom plate; the drying device is arranged at the right side of the water collecting groove; the drying device is installed on the bottom plate; and the traction device is arranged at the right side of the drying device and the traction device is installed on the bottom plate. The textile cloth after-treatment process provided by the invention solves the problems that whenexisting equipment is used for drying the textile cloth, the cloth is directionally dried, hot air is easy to dissipate around, thus the efficiency of drying the cloth by the hot air is reduced, in addition, the drying time of the cloth cannot be increased in a limited space, thereby reducing the drying efficiency; and meanwhile, the cloth cannot be scraped while the cloth is dried, the cloth isprone to wrinkles after being dried, which reduces the attractiveness of the cloth after being dried and reduces the drying effect.

Owner:倪邦强

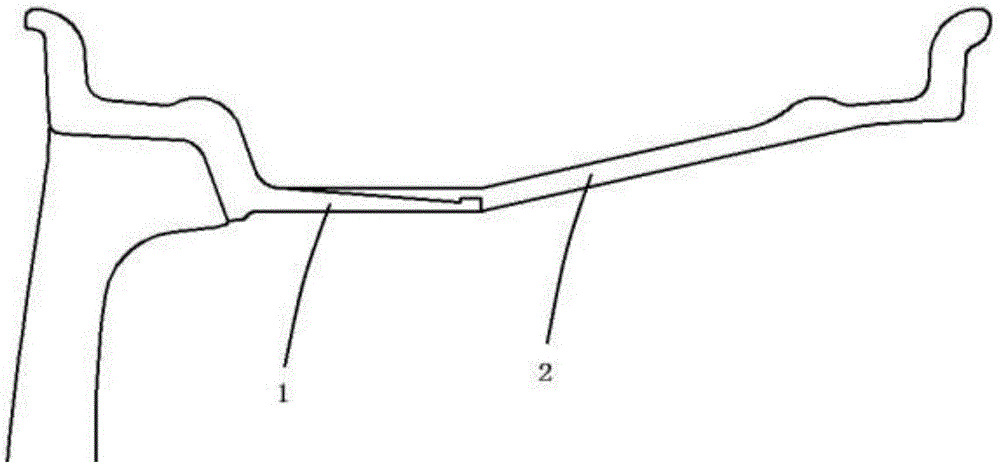

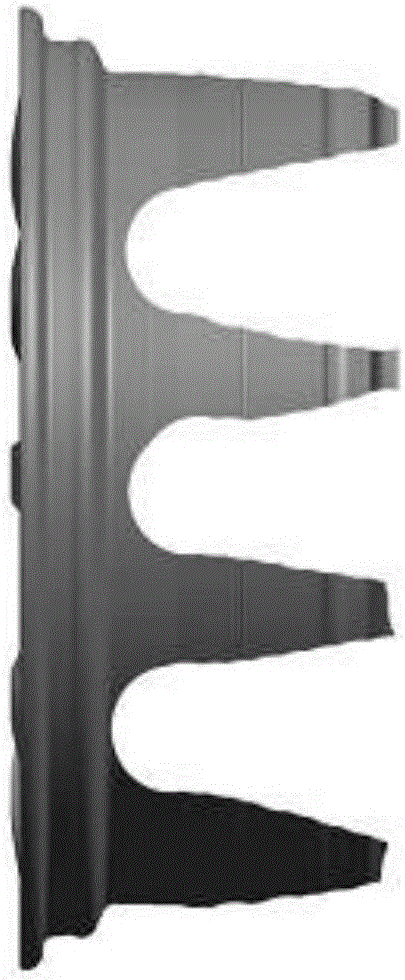

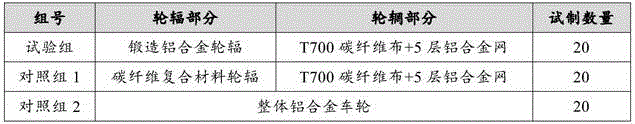

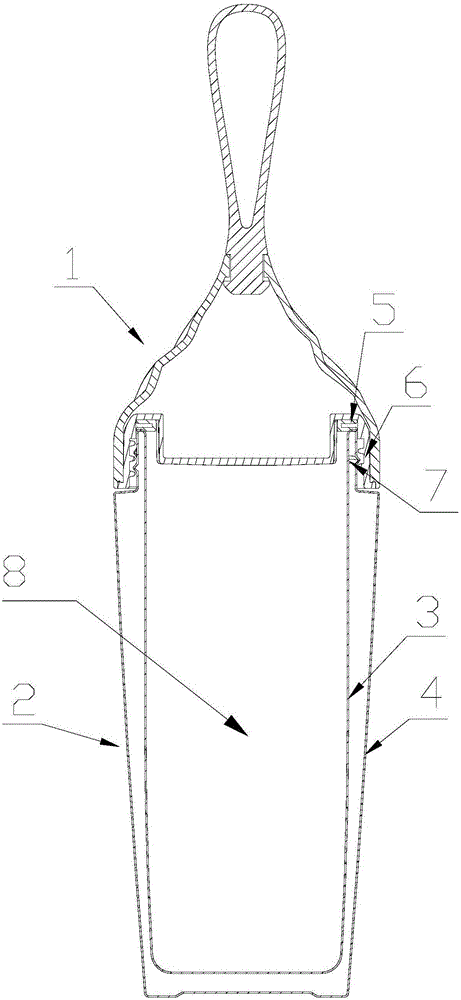

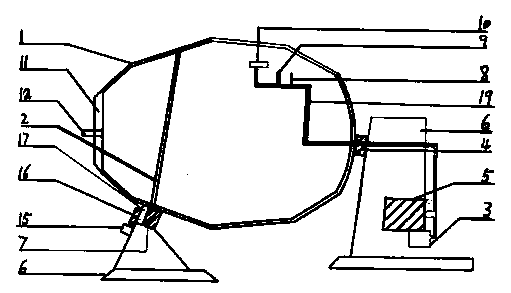

Aluminum alloy carbon fiber composite wheel and manufacturing method thereof

InactiveCN105711330AEasily lostLightweight effect is goodRimsNon-metallic wheel bodyFiber layerCarbon fiber composite

The invention provides an aluminum alloy carbon fiber composite material wheel and a manufacturing method thereof, which is composed of an aluminum alloy part (1) and a composite material part (2), and is characterized in that the aluminum alloy part includes a wheel spoke part and a wheel spoke part. The rim part of the wheel part, the rim part of the wheel part includes petal-shaped protrusions arranged along the side of the spoke part of the wheel; the composite material part (2) is attached to the surface of the rim part of the wheel part; and, the The composite material part (2) is composed of carbon fiber layers and metal mesh layers alternately stacked. The beneficial technical effect of the composite material wheel of the present invention lies in that heat dissipation and light weight of the wheel are two important performance indicators of the wheel, and this scheme is easy to transfer the heat inside the rim to the aluminum alloy part; this scheme is easy to make the heat pass through the aluminum alloy Part of it is lost; this scheme uses a variety of materials in combination, which has the effect of being easy to drive the wheel and reduces the weight; and the molding process of this scheme is simple.

Owner:CITIC DICASTAL

Air energy vacuum cup

The invention discloses an air energy vacuum cup which comprises a cup cover and a cup body, wherein the cup body comprises an inner layer and an outer shell; a closed air layer is arranged between the inner layer and the outer shell; an airtight water-storing heat-insulating space is formed at the opening at the upper end of the cup body covered with the cup cover; a heat-insulating function is achieved while the heat is easy to scatter; and a user can be effectively prevented from being scalded in the use process.

Owner:ZHEJIANG GINT VACUUM FLASK TECH CD LTD

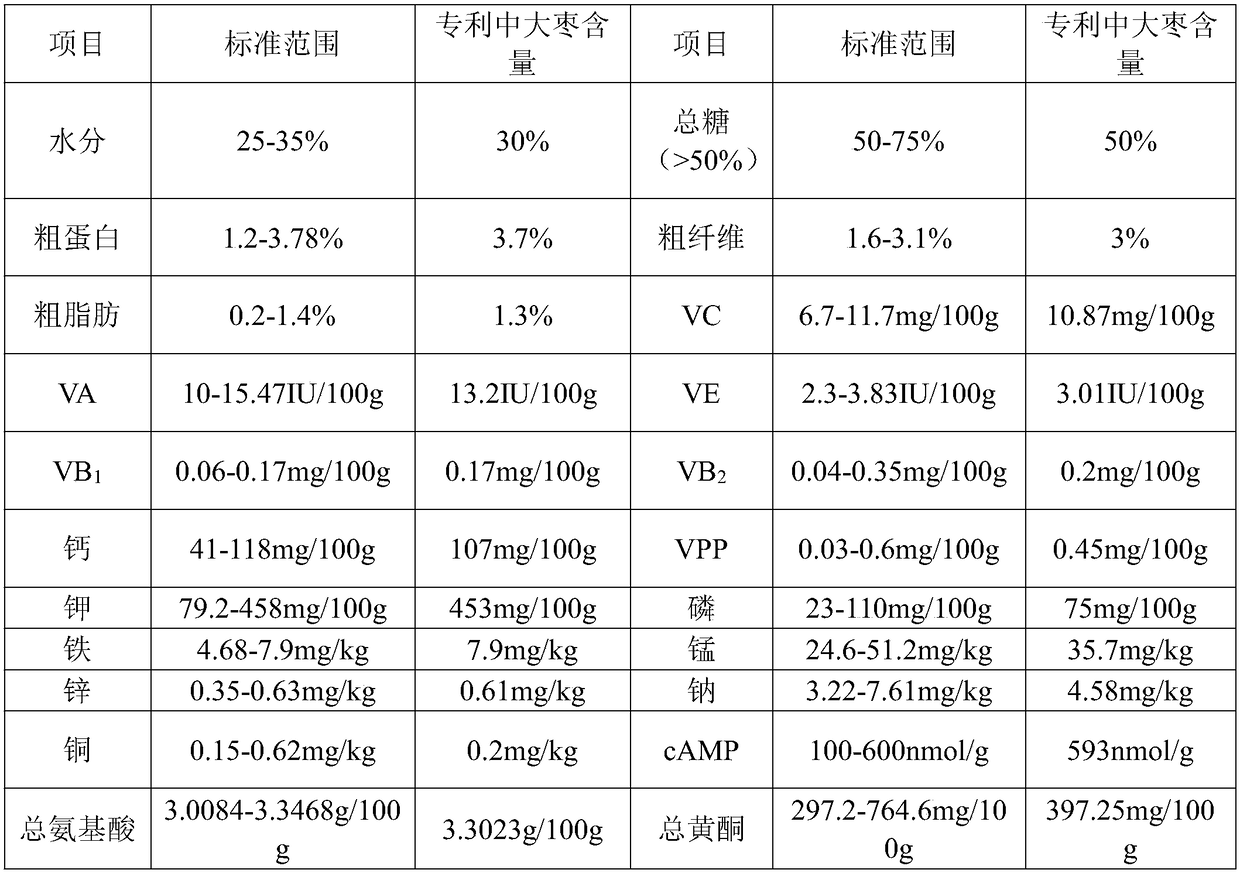

Production method and equipment of vacuum low-temperature baked jujube powder

The invention provides vacuum low-temperature baked jujube powder and a production method thereof. The prepared jujube powder produced through the production process combines the medicinal and ediblevalue of jujubes, can retain the original aroma of the jujubes, has crude fibers and a low water content, is thoroughly sterilized, has a long shelf life and is pure natural green health care food without any additive. The production method includes the steps of cleaning the jujubes, performing soaking, performing dehydration, performing baking, performing stacking, performing sterilization treatment on the prepared jujubes, performing grinding in a grinding machine to obtain the prepared jujube powder and performing sub-packaging. The prepared jujube powder produced through the method retainsthe nutrients and original flavor of the jujubes, also generates a plurality of new nutrients, has delicate particles and good rehydration performance, can be brewed directly with boiled water to drink as jujube pulp and also can be used as the auxiliary ingredient of food and drinks.

Owner:乔丹芳

Making method and equipment of lotus root powder through vacuum low-temperature baking

The invention provides lotus root powder obtained through vacuum low-temperature baking and a making method. Cooked lotus root powder made by a production technology has medical and edible effects oflotus roots, can maintain original fragrance of the lotus roots, is low in moisture content and crude fiber content, thorough in sterilization and long in quality guarantee period, and is a health-care food being free from any additives, purely natural and green. The lotus root powder is made through the following steps of thoroughly cleaning the lotus roots, performing soaking, performing dehydration, performing baking, performing stacking, performing sterilization on the cooked lotus roots, then performing crushing on the sterilized lotus roots with a crusher to obtain cooked lotus root powder, and performing subpackage as needed. The cooked lotus root powder processed by the method maintains nutrient components and original flavor of the lotus roots, and besides, many new nutrients arealso generated. The lotus root powder is fine and smooth in granules and good in rehydration properties, can be directly brewed with boiling water to obtain lotus root pulp to be drunk, and can also be used as ingredients of foods and beverages.

Owner:周童

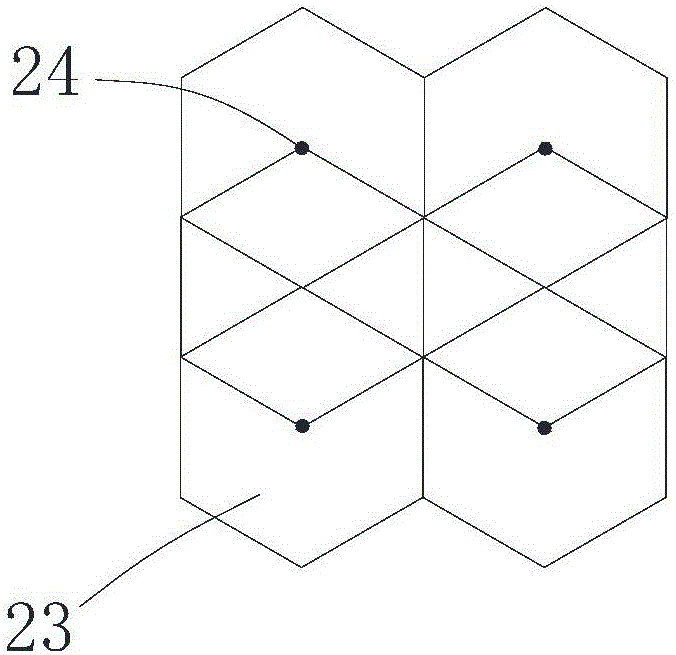

Metal honeycomb type vacuum multi-layer attenuation heat insulation plate

The invention discloses a metal honeycomb type vacuum multi-layer attenuation heat insulation plate. A multi-layer honeycomb structure is machined by adopting vacuum fusion welding, and the overall thickness is much lower than that of an existing single-layer honeycomb structure heat insulation plate. Heat transfer can be effectively blocked through multi-layer vacuum. Compared with an existing honeycomb heat insulation plate, the metal honeycomb type vacuum multi-layer attenuation heat insulation plate has the advantages of being light in structure, small in thickness, high in strength, long in service life and easy to machine and form, saving occupied space by 90% compared with traditional heat insulation materials, being capable of being widely applied to household appliances such as water heaters and refrigerators, thermos bottles, vacuum cups, household kitchen electric appliances and the like except for heat insulation and heat preservation of traditional buildings, traffic tools and large devices, greatly reducing heat loss, providing device energy consumption standards and completely eradicating fire risks caused by high temperature on electric devices, having the ultrathin size and the metal structure, being capable of being applied to the field where many traditional heat insulation materials cannot be applied, making a great contribution to energy conservation and emission reduction and being quite wide in application range.

Owner:孟庆义

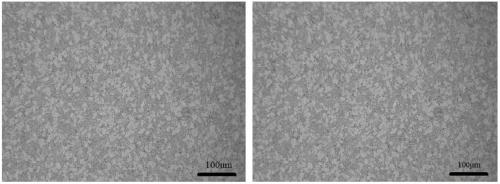

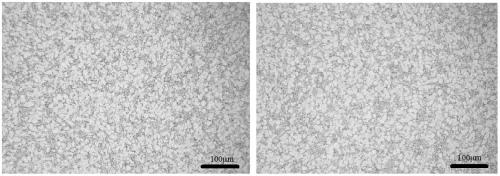

Crisp Chinese dates and processing technology thereof

InactiveCN108576715AHigh porositySweet and sourFood freezingVitamin food ingredientsPressure riseUltrasonic assisted

The invention relates to crisp Chinese dates and a processing method thereof. The method comprises the following steps: selecting whole green fresh Chinese dates which are free from insect damage, free from damage and free from crack as a raw material; performing disinfection, stoning, low-temperature fast-freezing, steam thawing and ultrasonic-assisted pressure-differential puffing; carrying outthe preparation of composite microcapsules; and conducting filing, packaging and sterilization to obtain a finished product. The method uses an ultrasonic-assisted pressure-differential puffing process, and utilizes the cavitation effect of ultrasonic, so that micro-gas-nucleus cavitation bubbles in the liquid rapidly grow and break down, and cell walls fracture so as to reduce pressure difference, and the optimal puffing effect can be achieved under the condition of small pressure difference. During the process of temperature rise and pressure rise, non-condensed gas nitrogen is used to dilute superheated steam so as to effectively avoid the problems such as uneven color and browning of the product caused by the superheated steam.

Owner:ZHONGXI TIANJIN JUJUBE TECH ENG CENT

Forging method of tc4 titanium alloy bar

Owner:湖南湘投金天钛业科技股份有限公司

Ice-temperature air adjusting fresh-keeping minced fillet foodstuff and production process thereof

InactiveCN1239101CLowering the freezing pointPollution controlFood preservationFood preparationGrass carpRaw material

The invention relates to a process for preparing minced fish food and products by using meat of fresh water fish such as silver carp, grass carp as raw material, and table salt, modified starch, konjac glucomannan, white sugar, smell removing agent as auxiliary material. The preparing process comprises smell removing, freezing point adjustment, germ-free cooling down, air regulation packaging, and ice temperature storage.

Owner:HUAZHONG AGRI UNIV

Low temperature baked natural red bean flour and making method thereof

InactiveCN104336519AAccurate temperature controlHeating evenlyFood preparationFood treatmentCooking & bakingFlavor

The invention provides a pure natural low temperature baked red bean flour and a making method thereof. The cooked red bean flour made by the production technology integrates the nutrition of red beans and red bean sprouts, has low moisture content, is thoroughly sterilized and has a long shelf life, and is pure natural green health food without any additive. The method includes: subjecting red beans to washing, scalding, soaking, dehydration, stacking and tabletting, processing the well pressed red bean sheets into cooked red bean sheets by low temperature baking equipment, conducting sterilization treatment on the cooked red bean sheets, then conducting grinding by a crushing machine to obtain the cooked red bean flour, and then carrying out packaging in bags according to requirements. The cooked red bean flour and cooked red bean sheets processed by the method maintain the nutrients and original flavor of red beans, and also have a lot of newly generated nutrients. With fine particles and better rehydration, the pure natural low temperature baked red bean flour can be directly brewed with boiling water into red bean soybean milk for drinking, and also can be used as an ingredient of food and beverages.

Owner:周童

Vacuum low temperature baked black soya bean flour and making method

InactiveCN104336516AHeating evenlyUniform heating temperatureFood shapingFood preparationBiotechnologyCrude fibre

The invention provides a vacuum low temperature baked black soya bean flour and a making method. The cooked black soya bean flour made by the production technology integrates the medicinal and edible value of green soya bean, can maintain the original fragrance of black soya bean, has low content of crude fiber and water, is thoroughly sterilized and has a long shelf life, and is pure natural green health food without any additive. The method includes: subjecting black soya bean to washing, soaking, dehydration, baking and stacking, conducting sterilization treatment on the cooked black soya bean flour, then performing grinding by a crushing machine to obtain the cooked black soya bean flour, and then carrying out packaging in bags according to requirements. The cooked black soya bean flour and cooked green soya bean powder processed by the method maintain the nutrients and original flavor of black soya bean, and also have a lot of newly generated nutrients. With fine particles and better rehydration, the vacuum low temperature baked black soya bean flour can be directly brewed with boiling water into black soya bean pulp for drinking, and also can be used as an ingredient of food and beverages.

Owner:周童

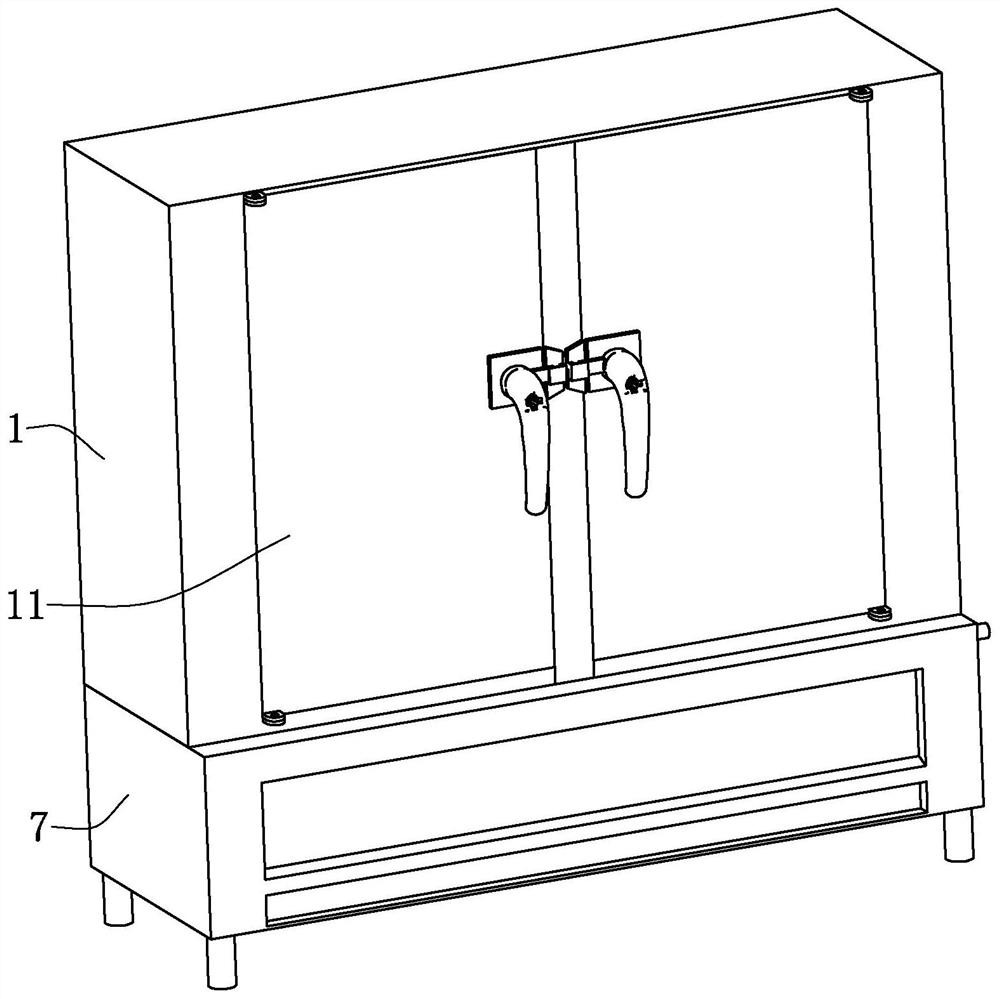

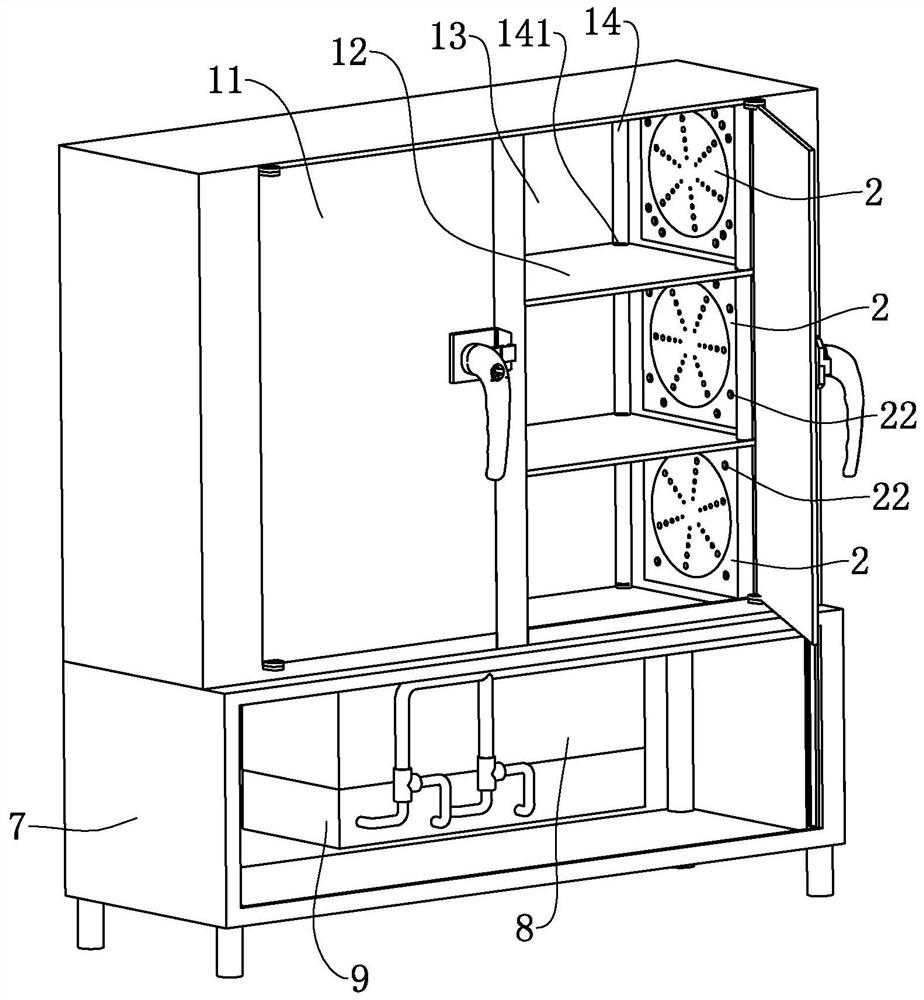

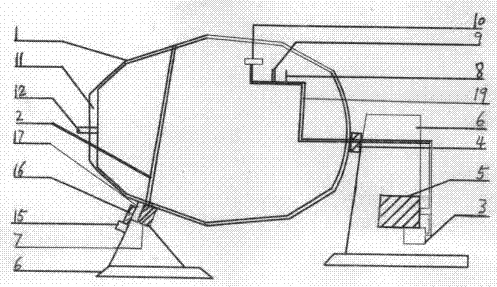

Large Gas Steamer

The application discloses a large-scale gas steamer, which includes a steamer. The steamer is connected with a water tank communicating with its inner cavity. The side of the water tank is provided with a combustion shell for heating it. The board and the partition divide the inner chamber of the steam box into three relatively independent heating chambers; the side of the inner chamber of the steam box is provided with a steam channel connected with the water tank, and the steam channel is vertically provided with three corresponding to the heating chamber; The side wall of the steam channel facing the middle of the steam box is the inner wall, and a plurality of ventilation holes are opened on the inner wall; a rotating shaft is respectively pierced on the steam channel, and a rotating disc in contact with the surface of the inner wall is fixed on the rotating shaft. There is a rotating hole that can communicate with the air hole, and the air hole can be covered when the rotating disc rotates; the rotating shaft is connected with a driving mechanism that drives it to rotate around its own axis. This application has the effect of making the steam distribution in the cavity uniform.

Owner:北京中威宏酒店设备有限公司

Recipe of health preservation tea substituting beverage and preparation method and equipment thereof

The invention provides a recipe of a health preservation tea substituting beverage and a preparation method and equipment thereof. The health preservation tea substituting beverage is prepared from semen juglandis, poria cocos, semen armeniacae amarae, fructus lycii, raw semen coicis, raw radix ginseng, astragali radix and fructus corni. The health preservation tea substituting beverage prepared by the production process can maintain raw fragrance of the traditional Chinese medical materials; coarse fiber is contained; the moisture content is low; the sterilization is thorough; the shelf lifeis long; the beverage belongs to a pure natural green health care product without any additives. The semen juglandis, poria cocos, semen armeniacae amarae, fructus lycii, raw semen coicis, raw radix ginseng, astragali radix and fructus corni are cleanly washed, soaked, dewatered, denucleated, baked and stacked; after the tea substituting beverage is subjected to sterilization treatment, the materials are ground through a crusher and are packaged into different bags according to requirements. The processed tea substituting beverage has the advantages that the nutrition ingredients and the original flavor of the medical materials can be maintained; meanwhile, various new nutrients are generated; the particles are fine; the reconstitution properties are better.

Owner:高欢

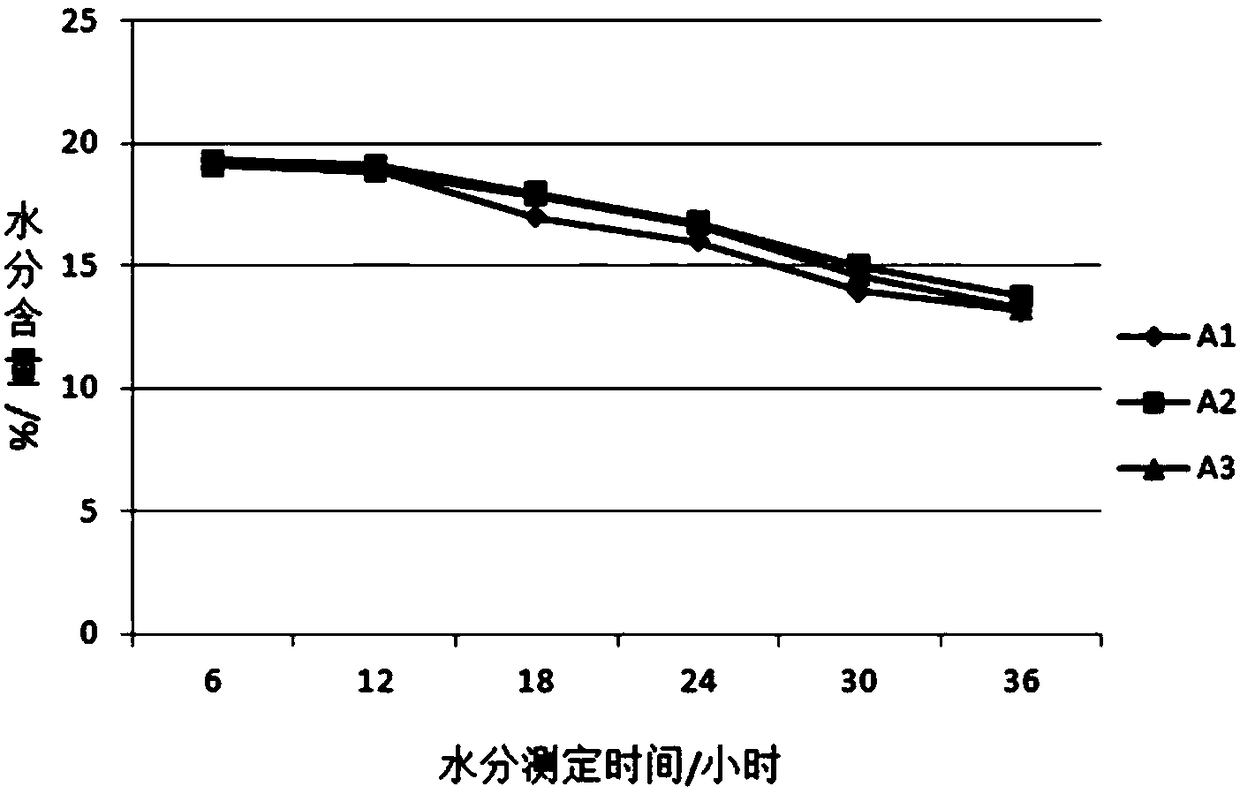

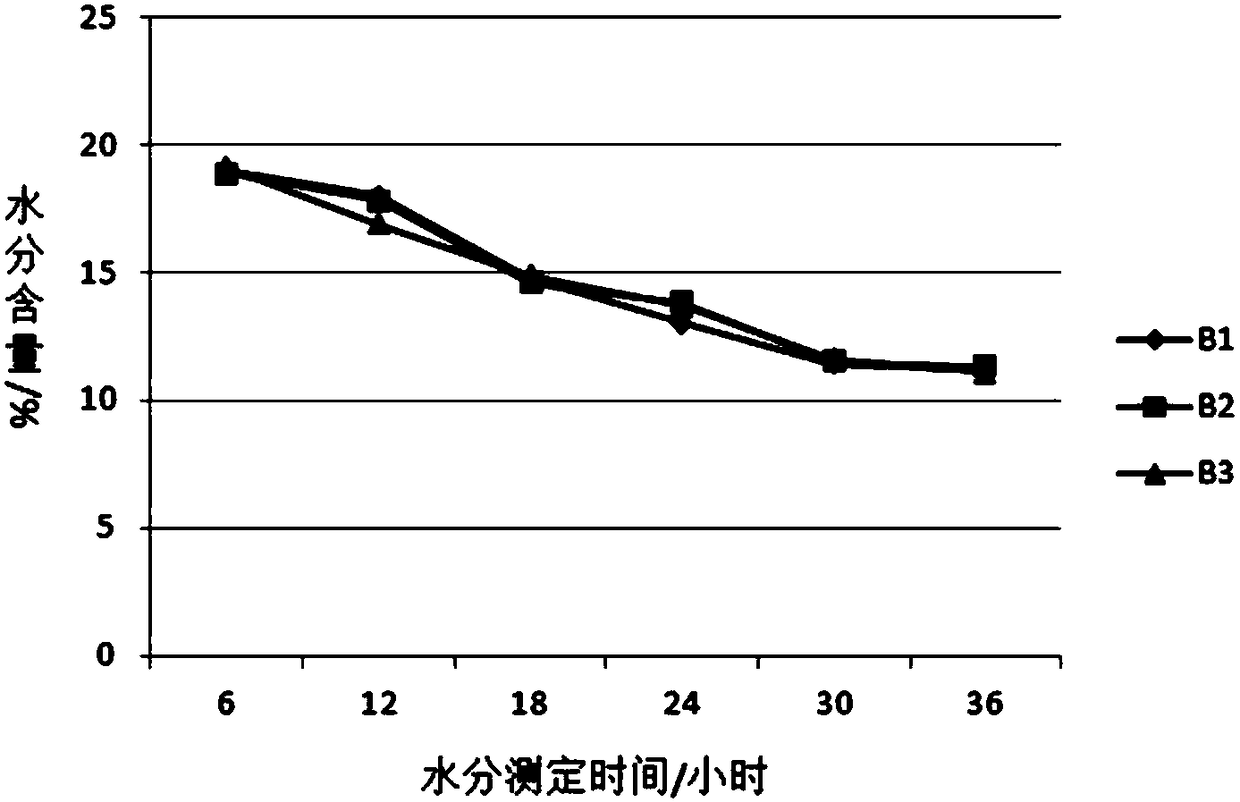

Airing method for increasing head rice yield of rice

InactiveCN108260664AImprove the rice polishing rateReduce moisture contentFood processingClimate change adaptationEngineeringTemperature difference

The application of the invention discloses an airing method for increasing head rice yield of rice. The airing method comprises the following steps of selecting cement ground which is thoroughly cleaned, and spreading a sorghum mat on the clean cement ground as the airing ground. The airing method further comprises an airing manner that a black sunshade cloth is used for shielding aired rice outdoors on daytime, before sunset in the afternoon, the aired rice is loaded into woven bags, and the woven bags are taken indoors. The airing method further comprises the step of uniformly spreading therice on the sorghum mat from 9:30am every day, and the sunshade cloth is used for shielding the aired rice; and the airing method further comprises the step of turning over the aired rice once at 11am. and turning over the aired rice once at 14pm. every day. According to the airing method disclosed by the invention, the rice is moved indoors at night, so that the temperature difference between theairing temperature on the daytime and the temperature at night is reduced, the crack rate is reduced, and the head rice yield is increased; and the situation that sun shielding airing treatment is related with the head rice yield of the rice is guaranteed, and the smaller the change of airing temperature is, the higher the head rice yield of the rice is.

Owner:袁米农业科技有限公司

Double-contact type load switch

PendingCN112117156AAvoid vibrationReduce damageHigh-tension/heavy-dress switchesAir-break switchesEngineeringMechanical engineering

The invention discloses a double-contact type load switch. The double-contact type load switch comprises a shell, a first contact part which is arranged on the peripheral wall of the shell, wherein afirst contact and a second contact are arranged on the first contact piece in a protruding mode, the first contact and the second contact protrude in the axial direction of the shell, and the first contact protrudes out of the second contact; a second contact part which is rotationally connected in the shell, can rotate around the axis of the shell and is used for being connected with the first contact and the second contact in a matched mode, wherein the second contact is closer to the second contact than the first contact. The first contact part is provided with the first contact and the second contact, and the first contact and the second contact are subjected to arcing, so that the separation distance between the first contact and the second contact and the second contact part can be shortened, and the arc extinguishing speed is increased; and the second contact is closer to the second contact than the first contact, so that the damage degree of the electric arc to the first contact can be reduced.

Owner:珠海沃顿电气有限公司

A method and device for preparing wax gourd powder by vacuum low-temperature baking

The invention provides a wax gourd powder baked in vacuum and low temperature and a production method thereof. The cooked wax gourd powder produced by the production process integrates the medicinal and edible uses of the wax gourd, can maintain the original fragrance of the wax gourd, has low crude fiber and moisture content, and is thoroughly sterilized and has a long shelf life. , is a pure natural green health food without any additives. It consists of washing, soaking, dehydrating, baking and stacking the wax gourd, sterilizing the cooked wax gourd and grinding the cooked wax gourd powder through a crushing machine, and packing them in separate bags according to requirements. The cooked winter melon powder and cooked winter melon powder processed in this way maintain the nutritional content and original flavor of the winter melon, and at the same time produce many new nutrients. The particles are fine and rehydratable. Used as an ingredient in food and beverages.

Owner:周忠新

The installation structure of the temperature sensing element of the miniature rice cooker

Owner:GUANGDONGEUROS AUTO SUPPLIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com