Large Gas Steamer

A gas-fired, large-scale technology, which is applied to kitchen utensils, household utensils, cooking utensils, etc., can solve the problem of low uniformity of temperature distribution in steamers, increase the uniformity of heating temperature distribution, reduce fuel consumption, and improve heating uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

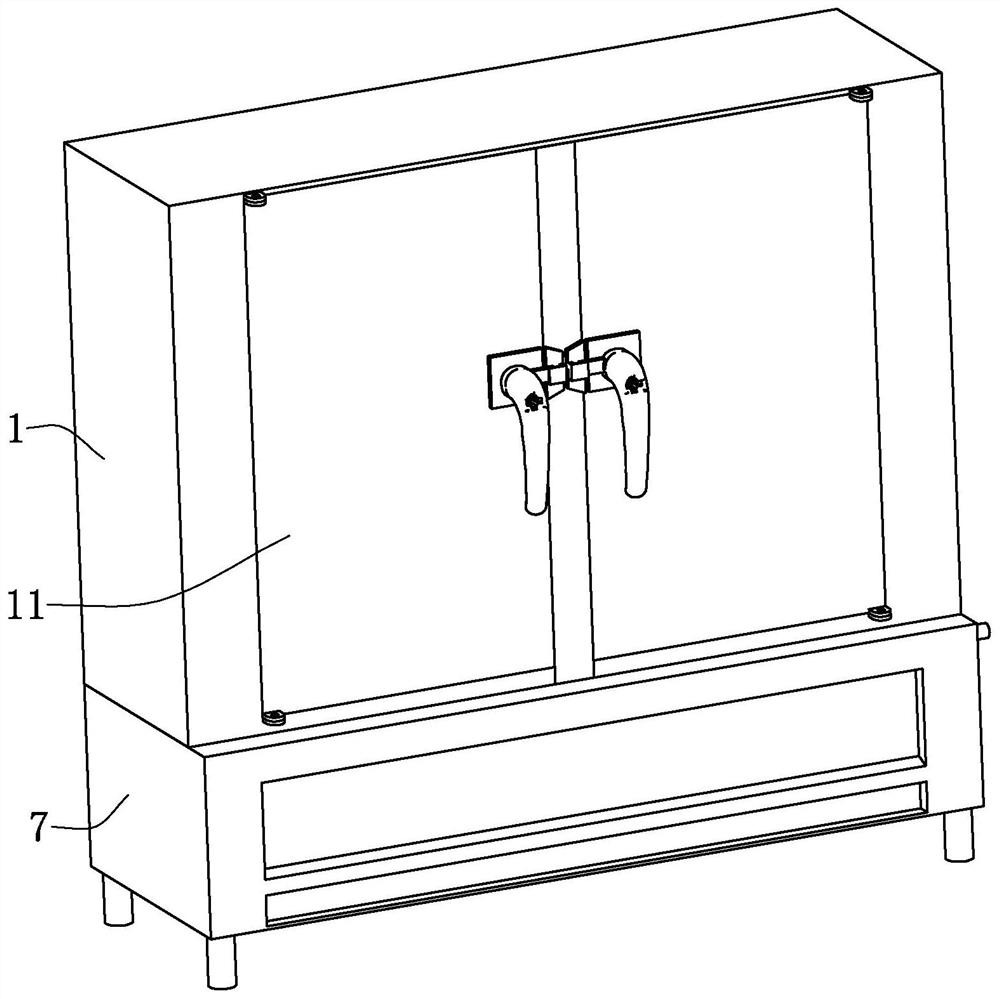

[0053] refer to figure 1 , discloses a large-scale gas steamer for the present application, including a bottom box 7 placed on the ground, the bottom box 7 is a rectangular shell, four end corners of the bottom wall of the bottom box 7 are respectively fixed with legs, 7 tops are fixed with steam box 1, and steam box 1 is a rectangular casing, and the side opening of steam box 1 is hinged with two box doors 11 that its opening is covered and sealed tightly.

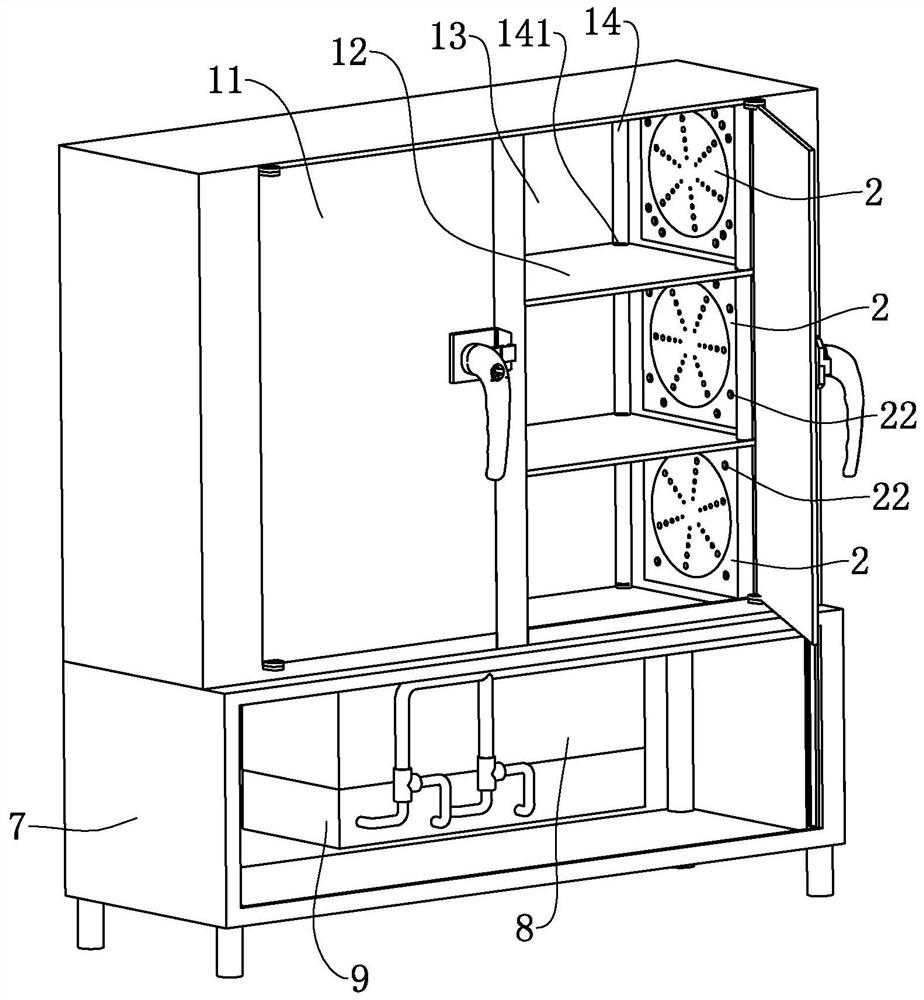

[0054] refer to figure 2 , the bottom box 7 inner chambers are fixedly connected with a water tank 8, and the water tank 8 is communicated with a water inlet pipe that feeds clear water into it. The combustion shell 9 is connected with a combustion head, and the combustion head sprays a mixture of gas and air into the combustion shell 9 to burn in the cavity of the combustion shell 9, and the combustion shell 9 is connected with a smoke exhaust pipe.

[0055] refer to figure 2 , the steam box 1 is evenly distributed ...

Embodiment 2

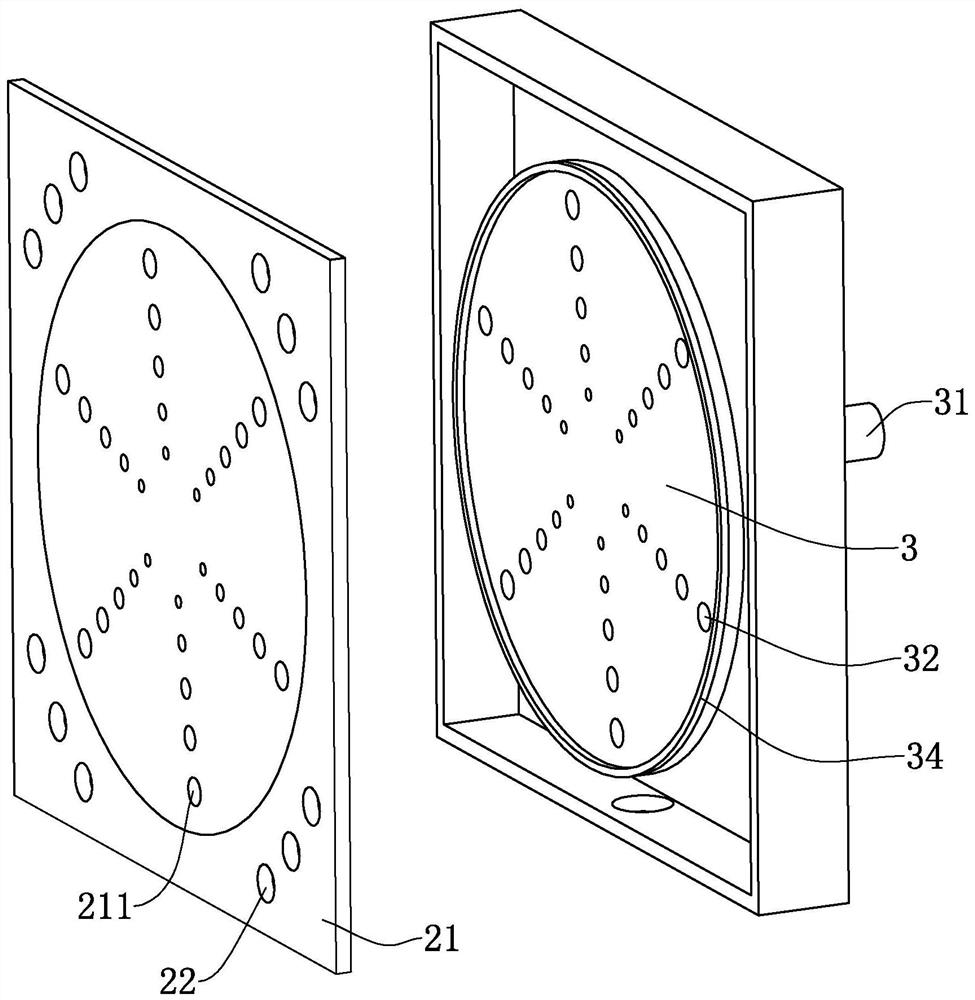

[0068] refer to Image 6, a large-scale gas steamer, the difference from Embodiment 1 is that the rotating shaft 31 includes an outer tube shaft 314 connected to the drive mechanism 4, the outer tube shaft 314 is a circular tube-shaped shaft body, and the outer tube shaft 314 faces away from the One end of the rotating disc 3 is a closed end, and a slide groove is provided on the side of the inner cavity of the outer tube shaft 314, and the length of the slide groove is arranged along the axial direction of the outer tube shaft 314. The rod shaft 315 is fixed with the rotating disk 3 after passing through the steam passage 2, and two sliding blocks located in the sliding groove are fixed on the outer side of the inner rod shaft 315, and the inner rod shaft 315 is limited by the sliding block and the sliding groove so that it can only move along the The outer tube shaft 314 slides in the axial direction, and the outer tube shaft 314 is provided with a compression spring 316 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com