Aluminum alloy carbon fiber composite wheel and manufacturing method thereof

A composite material and aluminum alloy technology, which is applied in the field of aluminum alloy + carbon fiber composite material wheels, can solve the problems of poor overall heat dissipation performance, heat accumulation, wheel deformation and failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

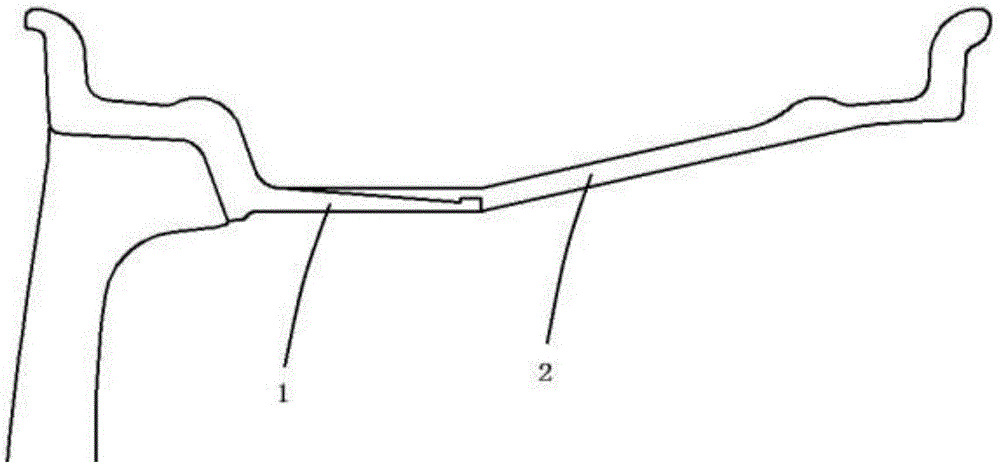

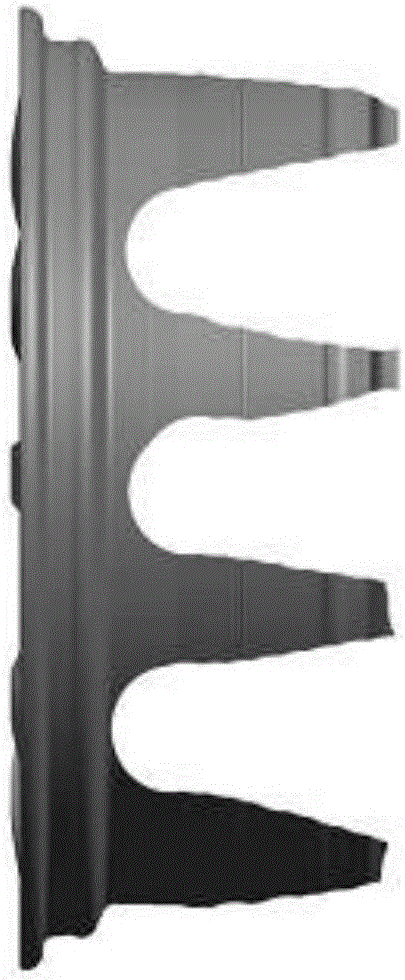

[0025] Such as figure 1 As shown, the present invention is an aluminum alloy + carbon fiber composite material wheel and its production method, including an aluminum alloy wheel spoke part 1 and a carbon fiber composite material rim 2 .

[0026] Unless otherwise stated, the carbon fiber cloth used in the present invention is:

[0027] (1) T700 carbon fiber cloth, which is a 12k fiber cloth, purchased from Jiangsu.

[0028] The resin material used in the present invention is: epoxy resin, purchased from Jiangsu.

[0029] The metal mesh used in the present invention is an aluminum alloy mesh, wherein the diameter of the aluminum alloy wire is 0.1 mm, 100-150 mesh, and the density is 150-200 g / square meter.

[0030] The spoke part in the present invention is made of aluminum alloy forging.

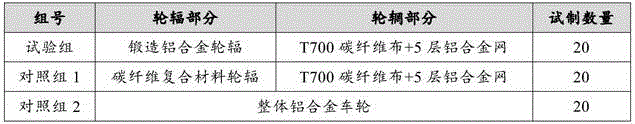

[0031] In the process of manufacturing wheels, 5 layers of metal mesh are laid while laying T700 carbon fiber cloth. The metal mesh and carbon fiber cloth are alternately combined to form ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com