Patents

Literature

48results about How to "Improve the rice polishing rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Breeding method of high-quality disease-resistant high-temperature-resistant rice two-line sterile line

ActiveCN104839010AImprove the rice polishing rateGood outbreeding characteristicsPlant genotype modificationBiotechnologyGermplasm

The invention relates to a breeding method of a high-quality disease-resistant high-temperature-resistant rice two-line sterile line, and belongs to the technical field of crop genetic breeding. The method is involved in rice germplasm breeding with long grain polymerization, high head rice rate and excellent economical characters such as high seed production temperature resistance and disease resistance, and the rice two-line sterile line with long grains, high head rice rate, high seed production temperature resistance, good out-crossing feature, stable fertility, good disease resistance and excellent comprehensive characters are bred. Great assembling is carried out by utilizing the sterile line, and a novel two-line hybrid rice assembly which is high in quality, disease-resistant and beneficial for seed production is screened out hopefully.

Owner:FUJIAN KINGSANTO DEV CO LTD

Breeding method for three-line sterile rice with high head rice rate and excellently-slender rice grains

InactiveCN107410003AEasy to shapeImprove the rice polishing ratePlant genotype modificationAgricultural scienceRice grain

The invention relates to a breeding method for three-line sterile rice with high head rice rate and excellently-slender rice grains and belongs to the technical field of genetic breeding of crops. The method relates to the breeding of high-quality cytoplasmic male sterile rice which is moderate in growth period, high in head rice rate and excellently-slender in rice grains after being cooked and has long grains. By matching the three-line sterile rice with a great number of restoring lines, a novel combination of high-quality three-line hybrid rice which has long rice grains and is high in head rice rate and excellently-slender in rice grains after being cooked is expected to be screened.

Owner:FUJIAN AGRI & FORESTRY UNIV

Rice ridge-pulverization ecological and efficient cultivation method

InactiveCN104115713AIncrease fertilizer and water retention performanceIncrease productionRice cultivationEnvironmental resource managementEngineering

The invention discloses a rice ridge-pulverization ecological and efficient cultivation method. The rice ridge-pulverization ecological and efficient cultivation method comprises the steps that an auger-bit machine enters soil and vertically rotates, wherein the machine enters the soil to the depth of 25-30 cm; ridge-pulverization soil drilling and fertilization are carried out at the same time, and the land is not harrowed so that bottom deep-layer soil will not be disturbed afterwards; meanwhile, ridge-pulverization deep rotary tillage does not need to be conducted again when second rice crop is planted, no tillage or only 3-4 cm shallow tillage is needed, stratification and air permeability of the bottom soil are kept, and field farm operation such as cultivation, weed control, fertilization, pesticide application and water management is conducted in a cooperative mode. The rice ridge-pulverization ecological and efficient cultivation method can effectively solve the problem that a traditional farming mode easily causes soil environmental degradation, effectively improve labor efficiency of ridge-pulverization cultivation, achieve the effect that deep ploughing is not needed within 3-4 years each time ridge-pulverization is conducted, and keep the stable yield and the yield increase of rice continuously, thereby having important value and significance in the field of rice cultivation.

Owner:广西壮族自治区农业科学院经济作物研究所

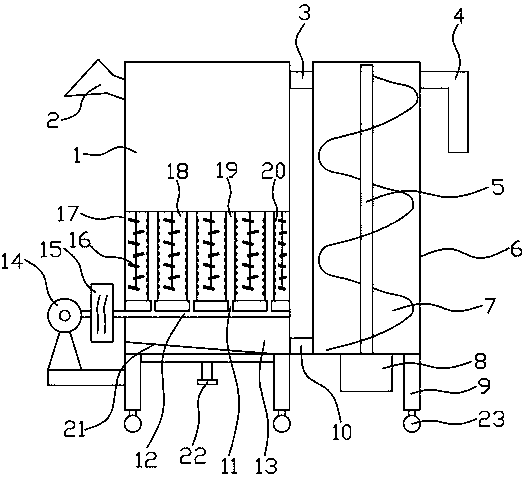

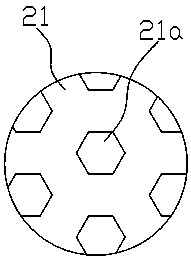

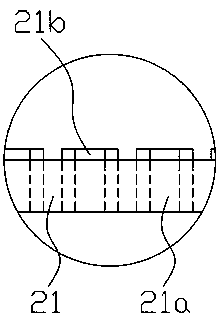

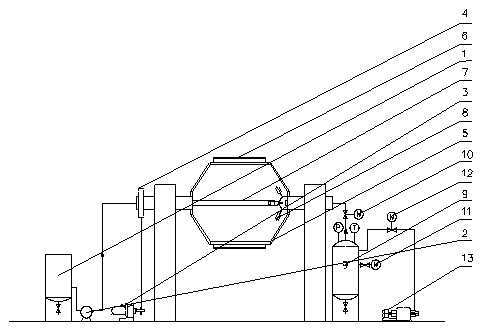

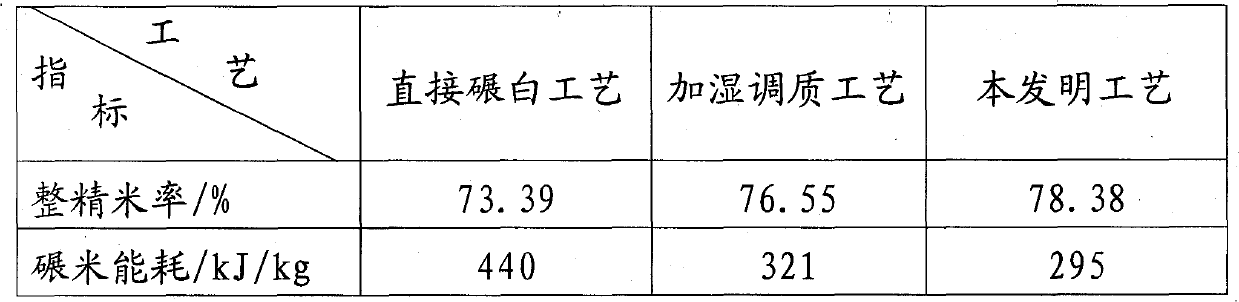

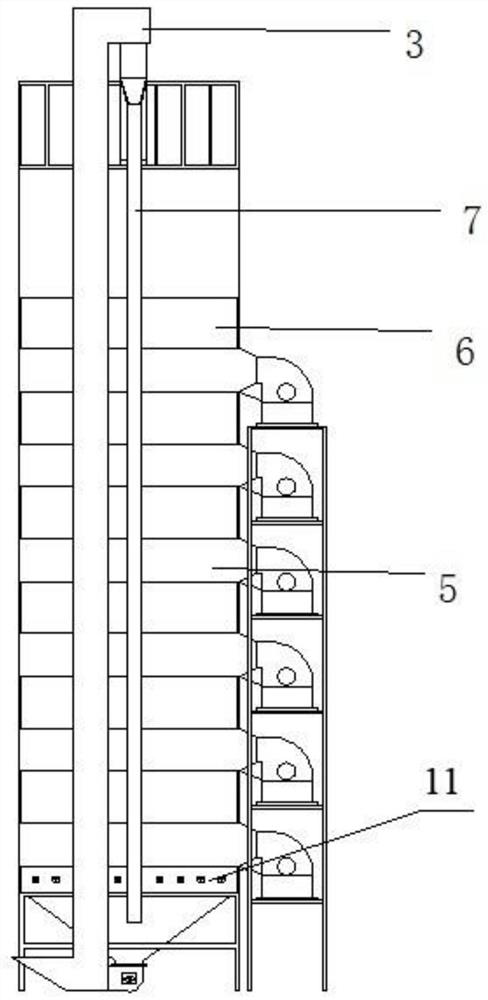

Multifunctional paddy drying device

InactiveCN108458583AImprove automation performanceImprove storage effectDrying gas arrangementsDrying chambers/containersPulp and paper industryAutomation

The invention discloses a multifunctional paddy drying device, and belongs to the technical field of paddy drying equipment. The device comprises a barn, where a drying chamber is connected to the lower end of the barn; a hot air system is arranged in the drying chamber; a drying tank is connected to the lower end of the drying chamber; a returning tank is connected to one side of the drying tank;a bottom door is arranged on the bottom part of the drying tank; a filter plate is inclinedly connected to the upper end of the bottom door; filter holes with the hole diameters being smaller than paddy particles are formed in the surface of the filter plate; and sponge rings consistent to the specifications of the filter holes are connected to the upper surfaces of the filter holes. The multifunctional paddy drying device provided by the invention is high in automation degree, simple and convenient to operate, fast in drying speed, high in uniformity and high in reliability; and after drying, the head rice rate of paddy is high, the edible quality of the paddy can be improved, and a storage property is prolonged.

Owner:浦江县晶富农业科技有限公司

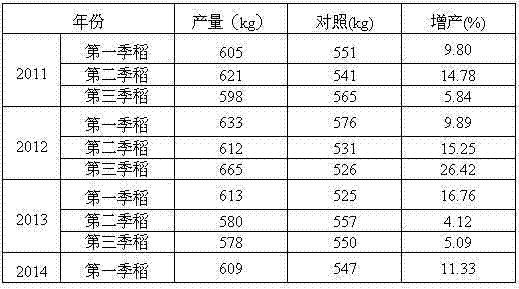

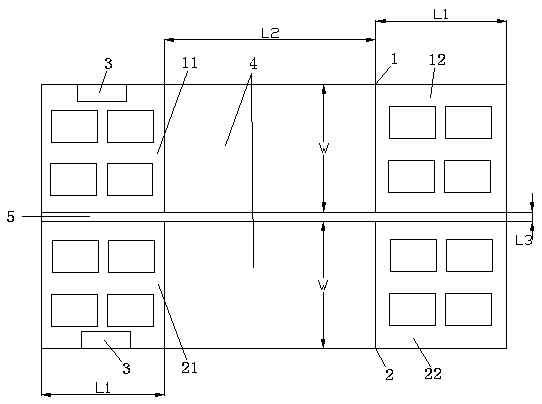

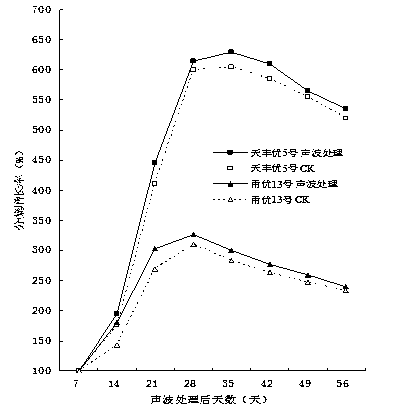

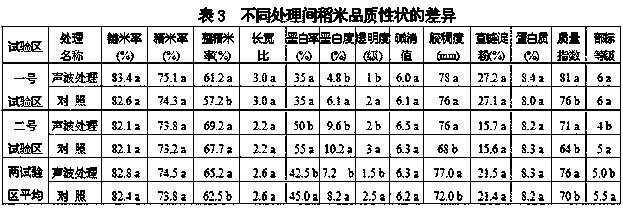

Paddy yield increasing cultivation method using acoustic wave treatment

InactiveCN103348891AImprove photosynthetic efficiencyIncrease chlorophyll contentHorticulture methodsRice cultivationSoil scienceAcoustic wave

The invention relates to a paddy yield increasing cultivation method using acoustic wave treatment. The paddy yield increasing cultivation method is characterized by comprising the following steps: (1) finely preparing a paddy field, uniformly and sparsely sowing seeds and cultivating strong seedlings with tillers; (2) finely preparing the soil before transplantation, applying sufficient basal fertilizer, rationally performing thick planting and timely transplanting; (3) playing acoustic wave with frequency of 300-6,000 Hz for 3 hours to treat each day after transplantation and 5 days before harvesting; (4) performing nutrient and water management according to local conditions in the field phase; and (5) timely preventing the disease pests and weeds according to prediction and forecast and the practical situation in the field and timely harvesting the paddy when 95 percent of grains in the whole field are yellow ripe. The paddy yield increasing cultivation method using acoustic wave treatment has the advantages of simple and rational design, capabilities of promoting growth and development of paddy and achieving yield increasing, high grade and anti-disease effects, excellent operability and better practicability, and can be widely applied to paddy production.

Owner:CHINA NAT RICE RES INST

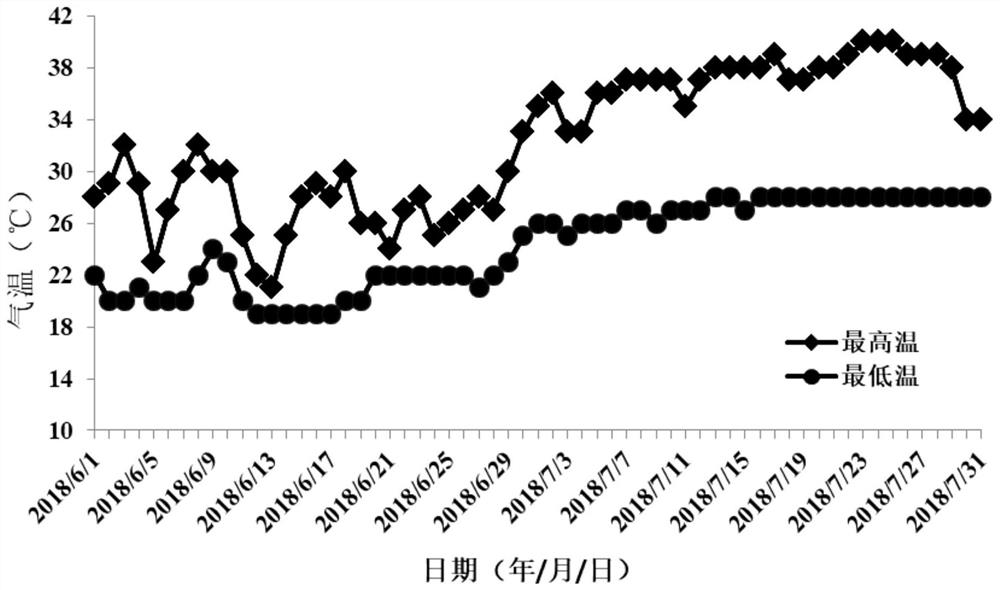

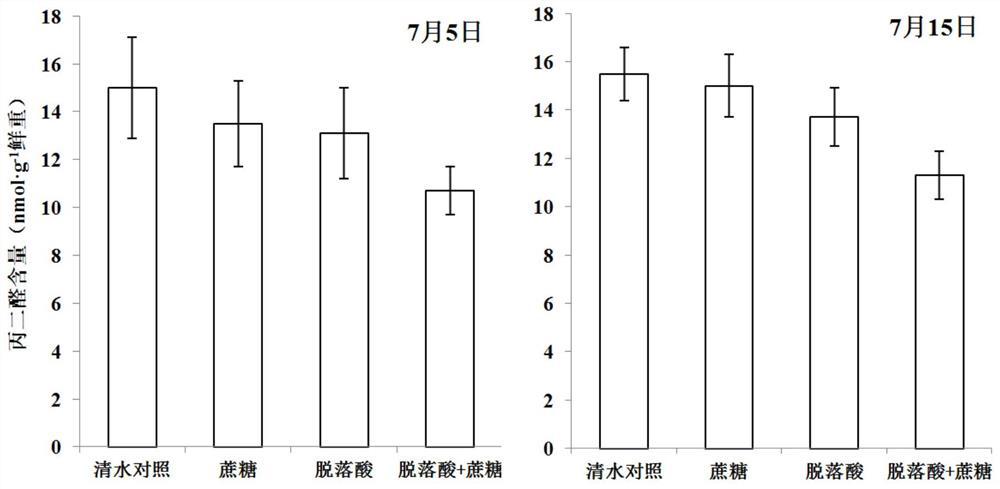

High-temperature-resistant rice plant growth regulator and using method and application thereof

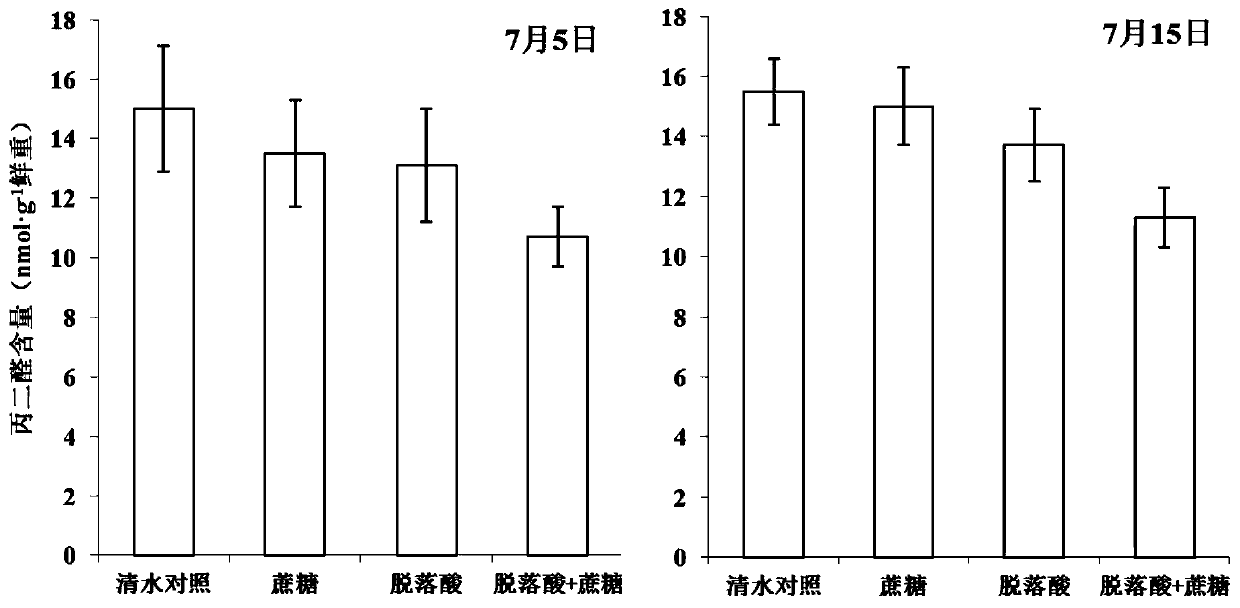

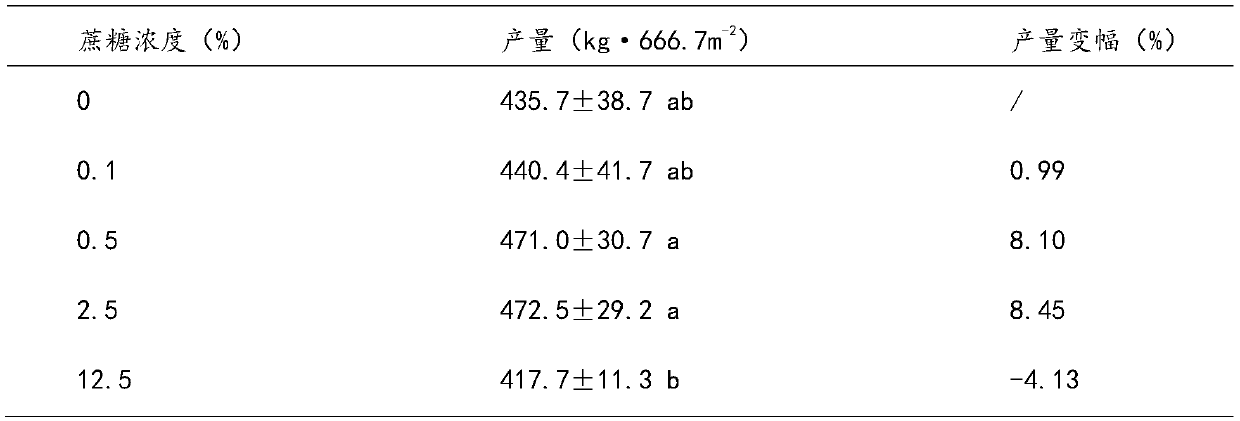

ActiveCN110663691AReduce heat damageIncrease productionPlant growth regulatorsBiocideBiotechnologyPlant hormone

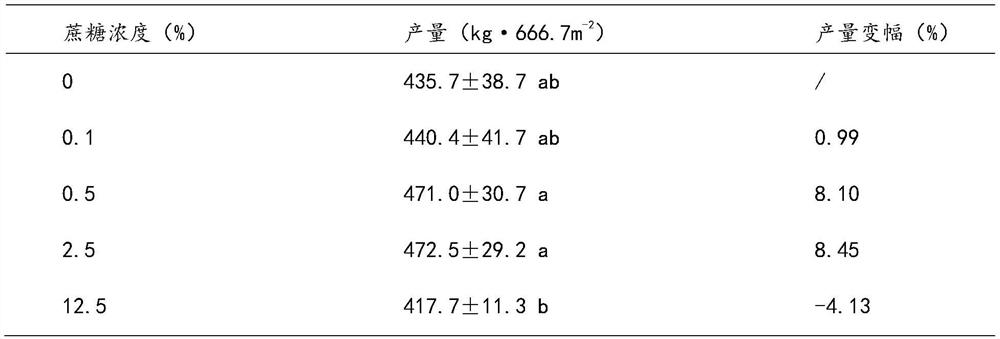

The invention discloses a high-temperature resistant rice plant growth regulator and a using method and application thereof, belonging to the field of promoting plant growth. The effective componentsof the regulator comprise abscisic acid and sucrose, and when in use, the concentration of the abscisic acid is 1-100 mu mol / L, and the sucrose accounts for 0.1-2.5% of the total mass of the regulator. According to the invention, based on the influence of the interaction of natural plant hormone abscisic acid and natural carbohydrate sucrose on the grain growth of rice after flowering, the optimalapplication concentration is screened, so that the high-temperature damage to the rice is remarkably reduced, the rice yield is remarkably increased, and the rice quality is remarkably improved.

Owner:CHINA NAT RICE RES INST

Method for planting selenium-rich rice by plant-derived humic acid organic fertilizers

ActiveCN110024642AReduce residual pollutionIncreased available selenium contentExcrement fertilisersBioloigcal waste fertilisersDiseaseMicrobial agent

The invention belongs to the field of rice planting methods, and particularly provides a method for planting selenium-rich rice by plant-derived humic acid organic fertilizers. The method includes thesteps: (1) rice seedling bed selection and arrangement; (2) seed disinfection and germination treatment; (3) sowing; (4) rice seedling management; (5) field selection, land preparation and application of the plant-derived humic acid organic fertilizers serving as base fertilizers prepared by mixing, crushing and fermenting 40-50% of sugarcane filter mud, 10-20% of rice husks, 10-20% of corncobs,20-30% of livestock excrement and urine, 5-10% of humic acid and 5-10% of microbial agents; (6) rice transplanting; (7) field water and fertilizer management; (8) disease pest and weed comprehensive control; (9) harvesting. Organic selenium in soil is activated by the organic fertilizers comprising organic materials such as the humic acid and agricultural by-products, selenium is enriched by a physiological mechanism of rice, addition of exogenous selenium is omitted, the applying quantity of chemical fertilizers is decreased, pollution caused by pesticide residues is reduced, the yield and the quality of the rice can be improved, and sustainable development of agricultural production is facilitated.

Owner:GUILIN ACADEMY OF AGRI SCI

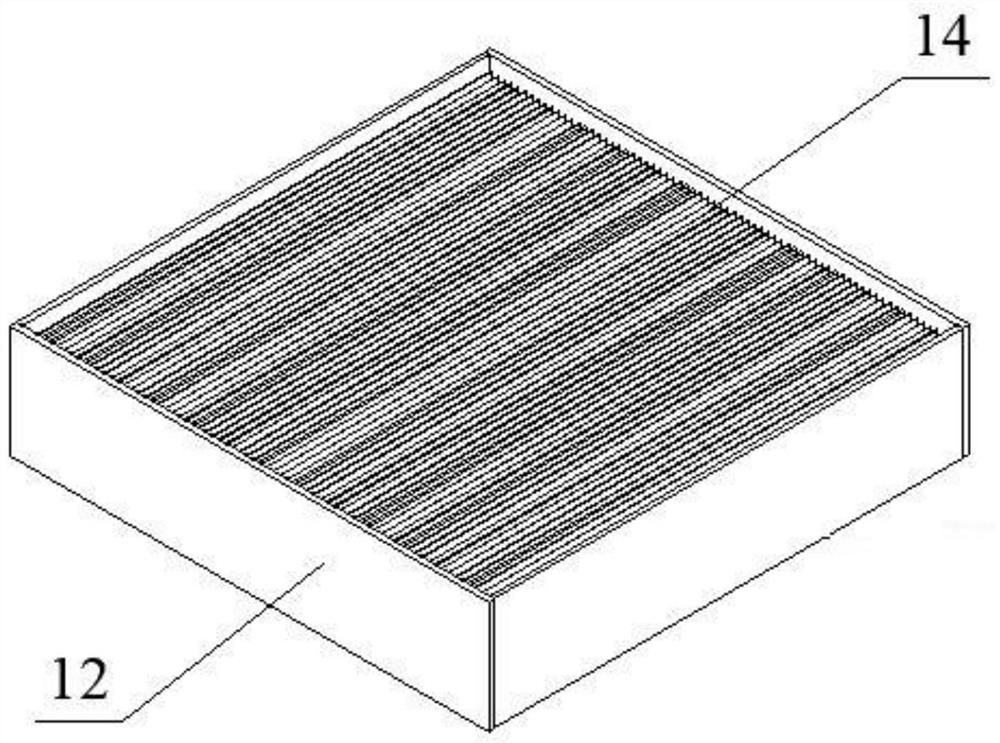

Production process high in embryo reserving rate and used for milled rice with embryos

The invention discloses a production process high in embryo reserving rate and used for milled rice with embryos. The production process includes the following sequential steps of winnowing, clearing,magnetic separation, husking, paddy separation, rice milling, white rice grading, polishing, color separation and packaging. According to the production process, due to the fact that the flow of unhulled rice entering a rice husking machine for milled rice with embryos, the rotating speed of the rice husking machine, and the rotating speed of a polishing rice brushing machine are controlled, thequality of rice grains is improved, the content of protein, vitamin, mineral substances and the like is increased by 60%-70% on an original cardinal number, the embryo reserving rate reaches 90% or above, dietary fibers are added, if people usually eat the milled rice, processed through the method, with the embryos, the blood viscosity of a human body can be better reduced, thrombogenesis is reduced, the metabolism of sugar in the human body is promoted, gastrointestinal peristalsis is increased, human body aging is reduced, human body microcirculation is improved, and muscle body fat is adjusted.

Owner:黟县有农生态农业有限公司

Organic rice processing technology

InactiveCN110479401AReduce power consumptionRice works wellGrain millingBroken ricePrimary screening

The invention provides an organic rice processing technology, and relates to the field of organic rice. After rice is mature, the rice is subjected to primary screening by using a vibrating screen, sothat hulls, dust, straw and other debris mixed in the rice are removed, the rice obtained after primary screening is placed into a stone removal machine, and stones, clods and other heavy debris mixed in the rice are removed. Through the technical steps of primary screening of the vibrating screen, stone removal of the stone removal machine, soaking and drying, husking, brown rice selection, brown rice refining, wetting with water, rice milling by using a rice milling machine, multi-stage polishing, color sorting and grading and packing and storage, the rice effect is better, brown rice refining can improve the technical effect of rice milling, less broken rice is generated, the head rice rate is high, the rice is bright, clean and lubricant in color, and moreover, the rice milling powerconsumption can be reduced.

Owner:安徽省淏天农业科技有限公司

Clean-production fertilization method of controlled-release nitrogen fertilizer for paddy-rice seedling raising

InactiveCN107318333AIncrease profitImprove qualityFertilising methodsRice cultivationControlled releaseSeedling

The invention relates to a clean-production fertilization method of controlled-release nitrogen fertilizer for paddy-rice seedling raising, is mainly applied to the synchronous fertilization during the paddy-rice seedling raising, and belongs to the technical fields of the reasonable amount-reduced application of novel fertilizer and agricultural clean production. The clean-production fertilization method is characterized by comprising the following steps of (1), taking a seedling raising tray for later use, taking the controlled-release nitrogen fertilizer for later use, and taking paddy-rice seedling raising nutrient soil for later use; (2), according to the paddy-rice seedling transplantation row spacing of 30cm is multiplied by 12cm and the seedling transplantation area, which is 36m<2> to 42m<2>, of the seedling for each tray, controlling to use 110g to 120g of seed for each tray and using 1.05kg to 1.1kg of the controlled-release nitrogen fertilizer for each tray; (3), taking and adding 2L of the paddy-rice seedling raising nutrient soil into the seedling raising tray, flattening, and drenching by using water; weighing, taking and uniformly sprinkling the controlled-release nitrogen fertilizer on the paddy-rice seedling raising nutrient soil. As the controlled-release nitrogen fertilizer has the characteristic of being long in release period and is also concentrated near a root system of paddy rice, in comparison with a conventional fertilization method, the use level of nitrogen fertilizer in the clean-production fertilization method can be decreased by 30 to 40 percent.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT NINGXIA ACAD OF AGRI & FORESTRY SCI NINGXIA KEY LAB OF SOIL & PLANT NUTRITION

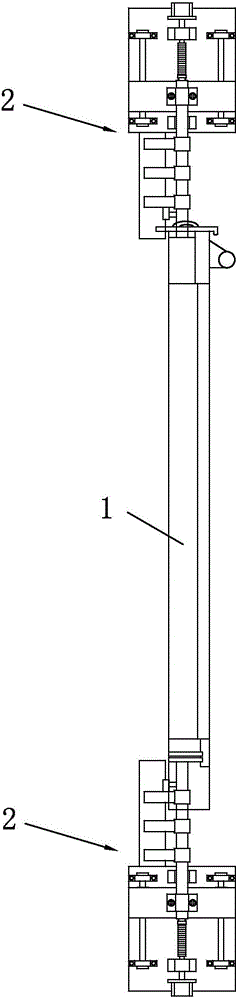

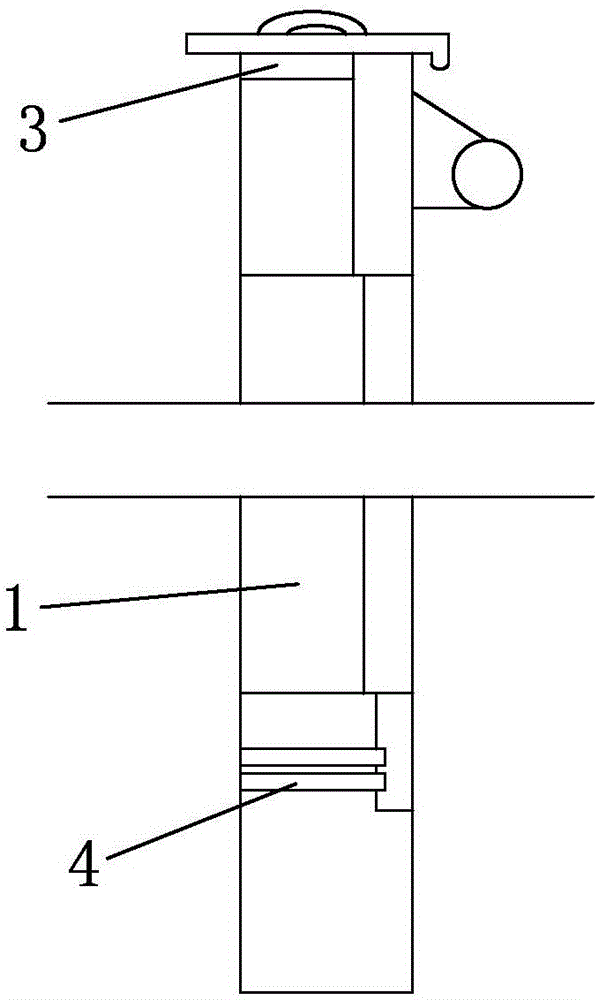

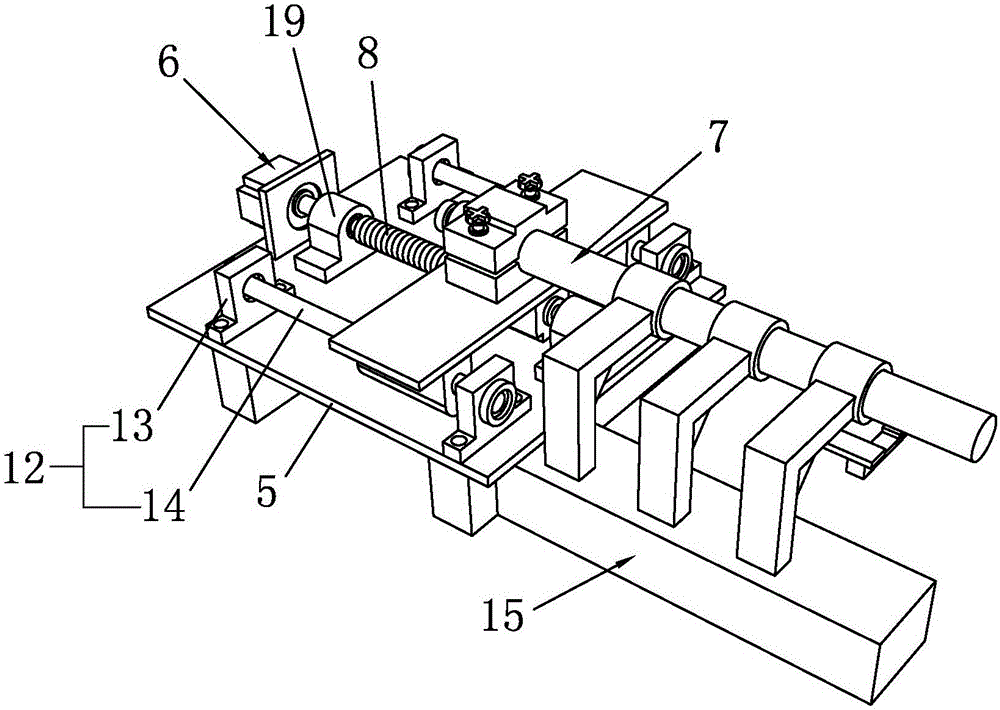

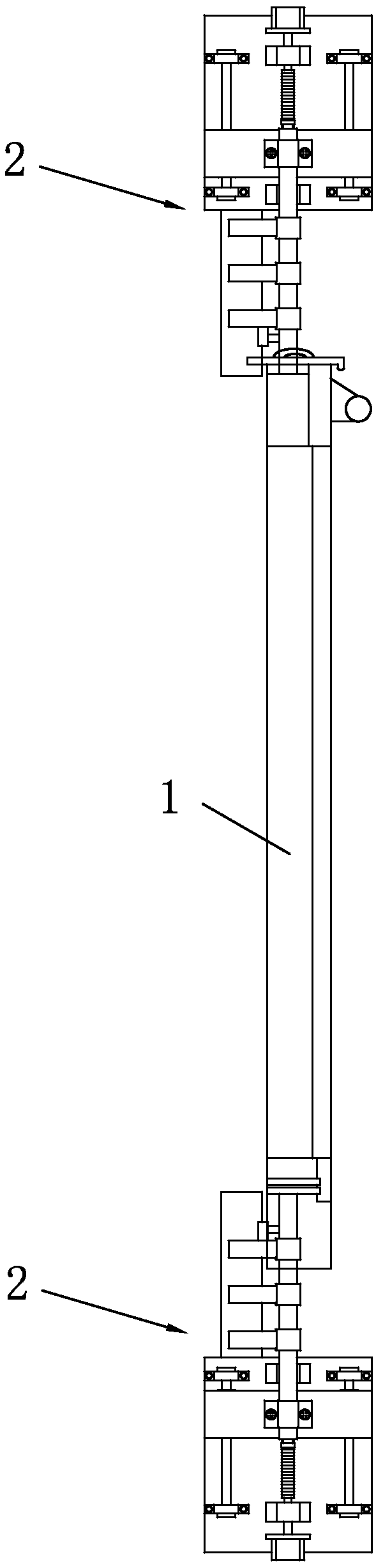

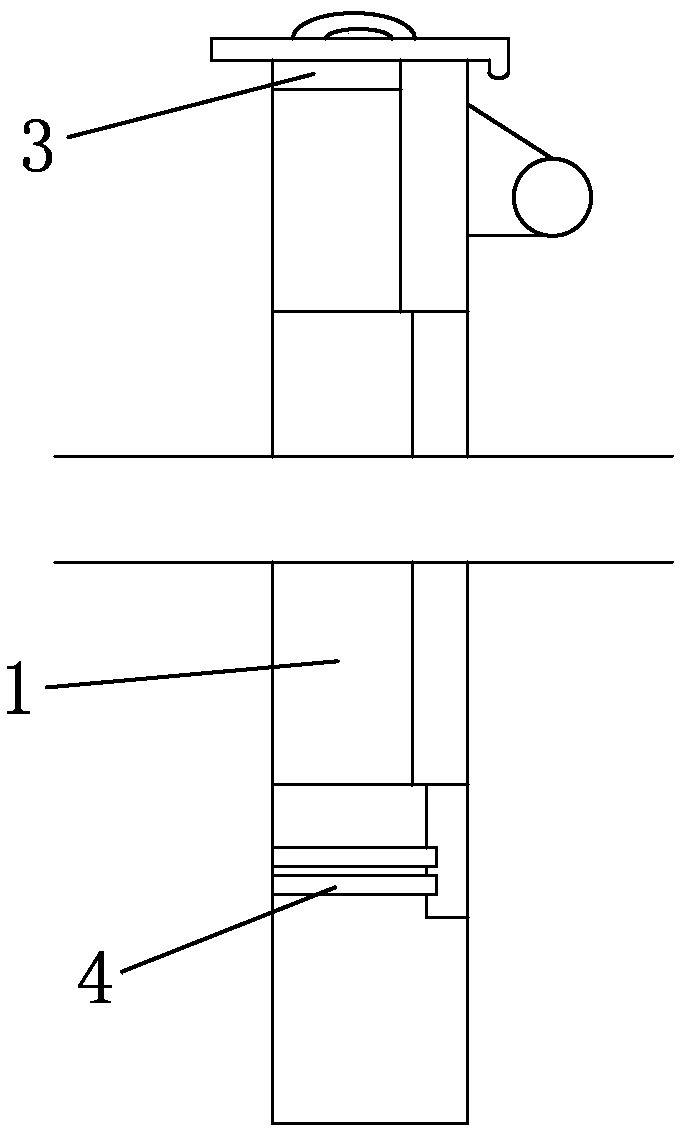

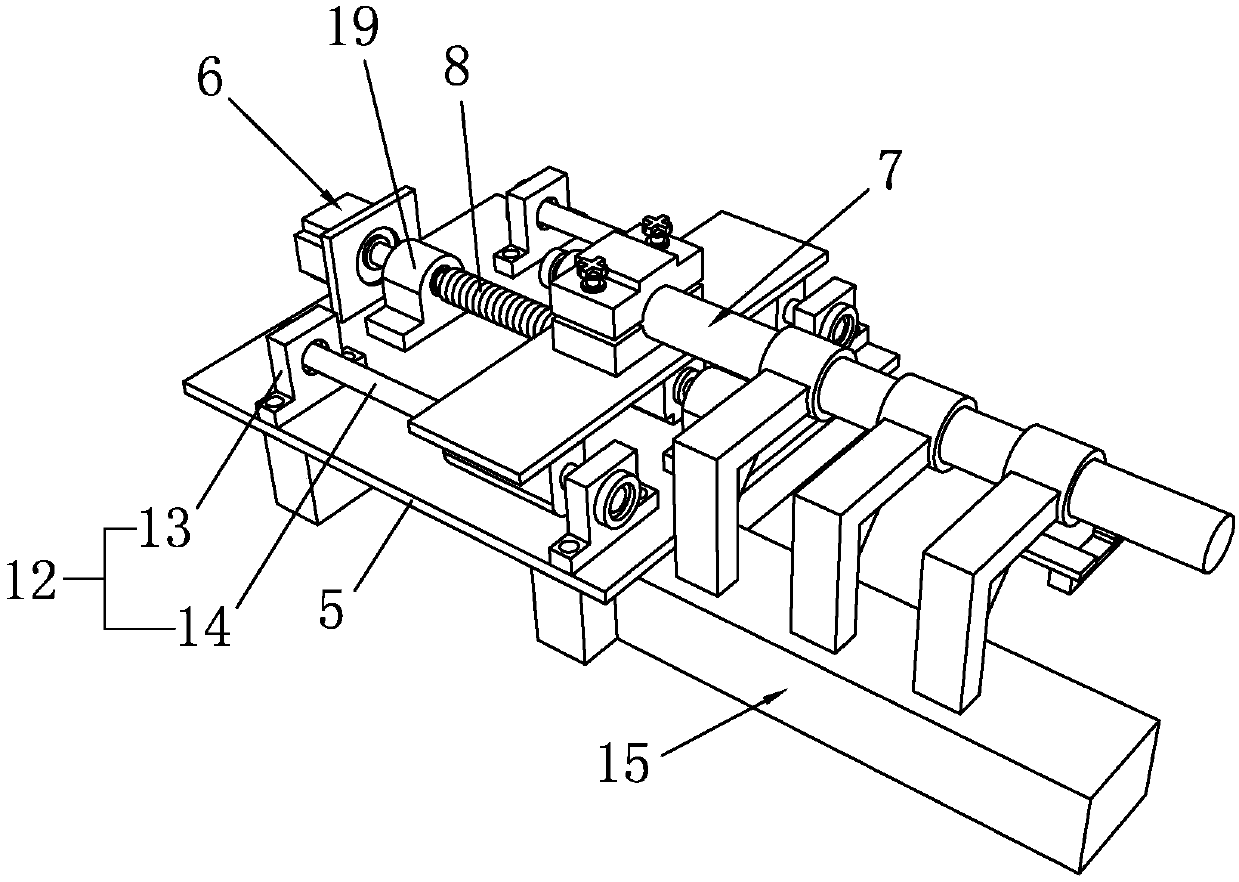

Control method and device for rice milling chamber feeding and discharging

ActiveCN106311381AImprove work efficiencySafe and reliable workGrain treatmentsControl engineeringAgricultural engineering

The invention discloses a control method and device for rice milling chamber feeding and discharging. The control method includes the steps of (a) early-stage preparation, (b) traction rod position adjustment, (c) rice milling chamber feeding and discharging pre-commissioning, (d) rice milling chamber allocation adjustment, (e) rice milling chamber feeding and discharging regulation and control, and (f) hydraulic device working pressure adjustment. The device comprises a rice milling chamber and control mechanisms. A rice feeding movement valve is arranged at one end of the rice milling chamber, and a rice discharging movement valve is arranged at the other end of the rice milling chamber. Each control mechanism comprises a workbench, a hydraulic device and a traction mechanism. Each hydraulic device is provided with a pushing rod. Each traction mechanism comprises a traction base and a traction rod. The pushing rods are connected with the corresponding traction bases. By means of the control method and device, a feeding inlet meeting the size requirement of rice species and a discharging outlet meeting the size requirement of the rice species are started according to the categories of specific rice species, so that the sizes of the inlet and the outlet are effectively controlled, time and labor are saved, rice losses are reduced, and the head rice rate is increased. The control effect of the device is good, moreover, the control process can be completed only through two persons, and cost is reduced.

Owner:麦稻智慧粮食有限公司

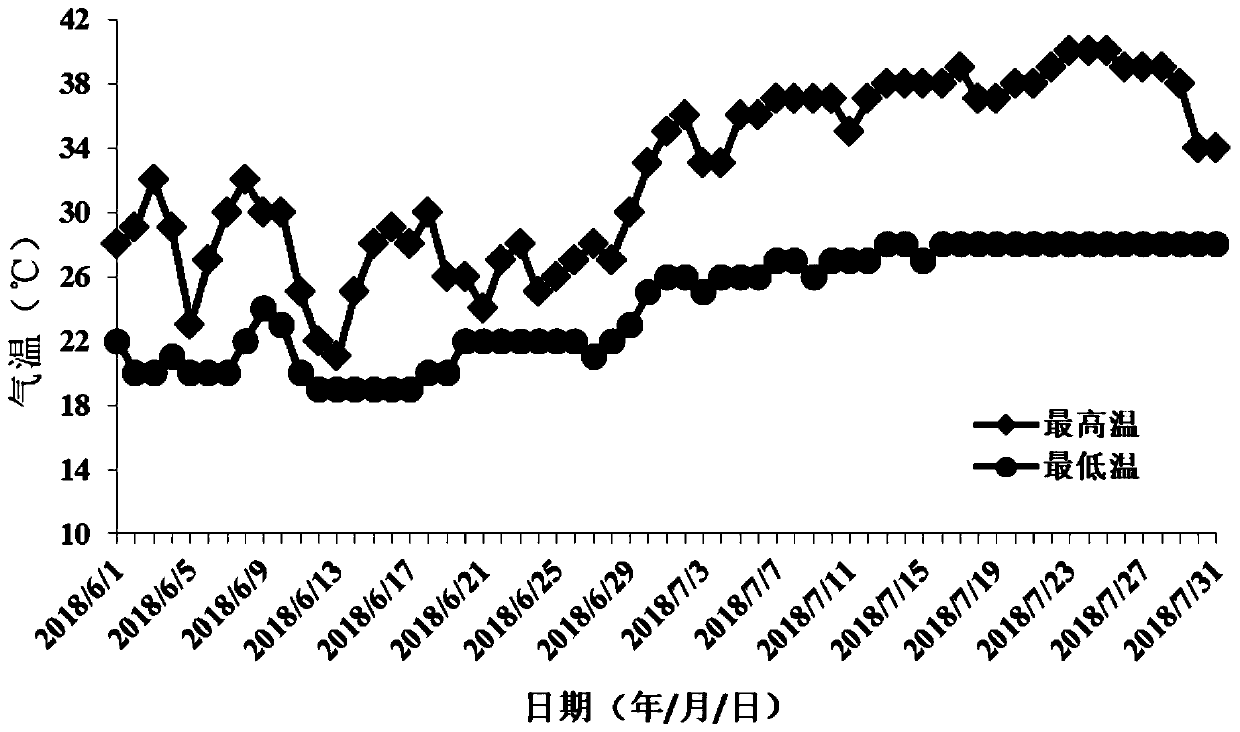

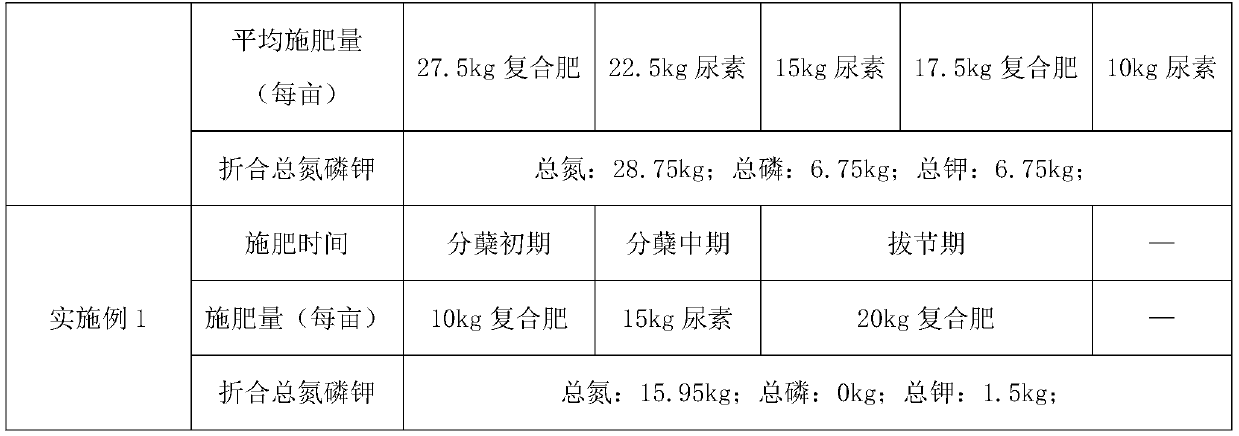

Dual-purpose three-harvest quality-improving and efficiency-improving cultivation method for rice

InactiveCN113099992AImprove qualityImprove the rice polishing rateFertilising methodsRice cultivationFodderRice farming

The invention provides a dual-purpose three-harvest quality-improving and efficiency-improving cultivation method for rice. The dual-purpose three-harvest quality-improving and efficiency-improving cultivation method for the rice comprises the following steps of variety selection, sowing, transplanting, first-season forage grass fertilization, first-season forage grass moisture management, first-season forage grass mowing, second-season ratooning rice fertilization, second-season ratooning rice moisture management, second-season ratooning rice harvesting, third-season forage grass fertilization, third-season forage grass moisture management and third-season forage grass mowing. According to the dual-purpose three-harvest quality-improving and efficiency-improving cultivation method for the rice, the problems of high edible rice yield and poor rice quality caused by high temperature stress in summer and high rice forage grass yield and poor rice quality of rice in the middle and lower reaches of Yangtze River in China can be effectively solved, and the problems of low utilization rate of temperature and light resources in rice planting and tension supply of high-quality animal feed in regions can be effectively solved.

Owner:CHONGQING ACAD OF AGRI SCI

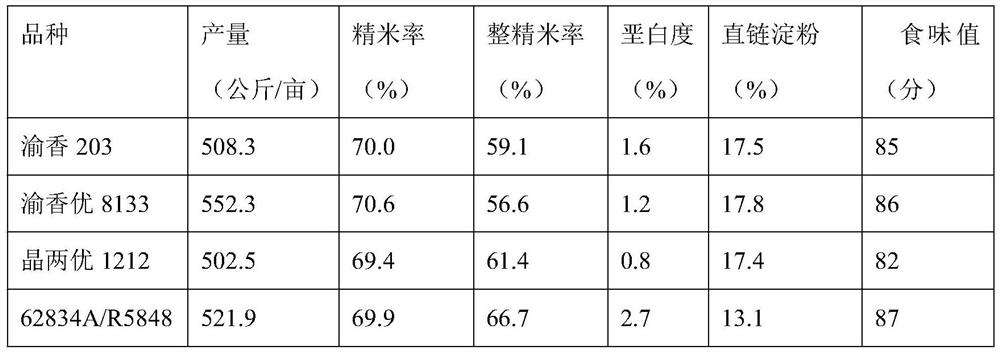

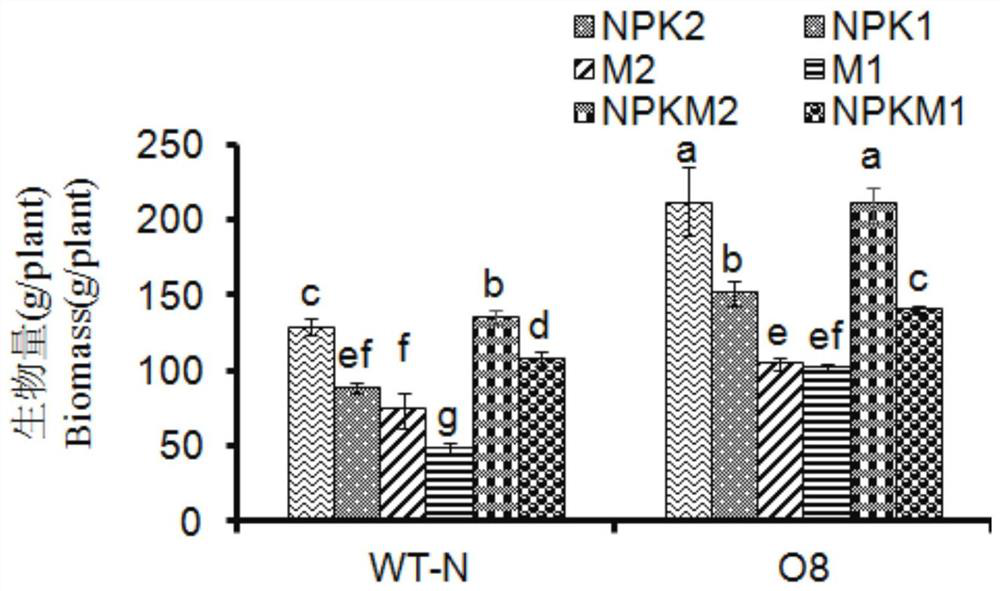

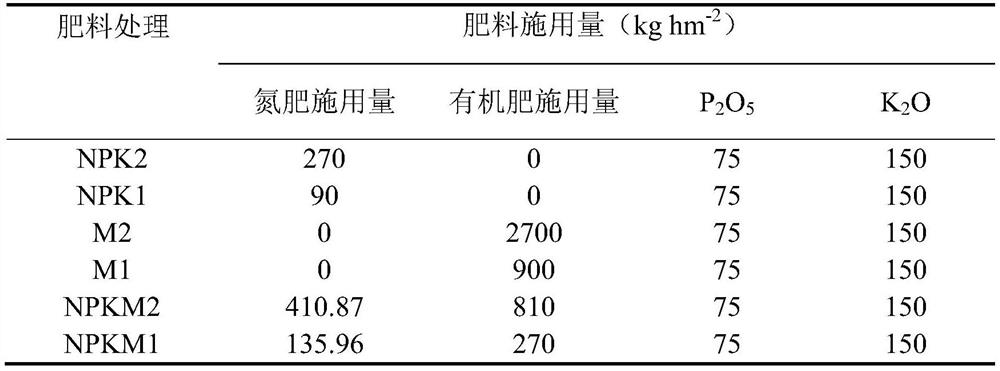

Application of OsNRT2.3b to increase of yield and improvement of quality of oryza sativa

ActiveCN111793633ABrown rice rate is highImprove rice milling ratePlant peptidesFermentationOryza sativaBrown rice

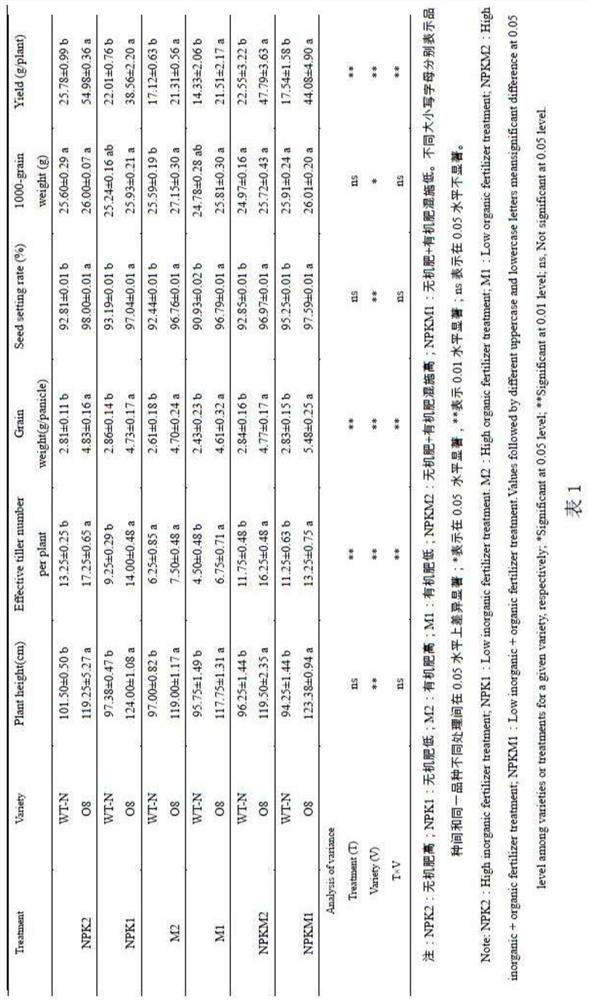

The invention discloses application of OsNRT2.3b to increase of yield and improvement of quality of oryza sativa. Under different fertilizer treatment conditions, effective tillering, weight per ear,yield per plant, brown rice rate and head rice yield of a total OsNRT2.3b overexpression material are higher than those of Nipponbare wild oryza sativa; and moisture content and length-width ratio arehigher than those of the Nipponbare wild oryza sativa, and chalky grain percentage and chalkiness degree are both lower than those of the Nipponbare wild oryza sativa.

Owner:NANJING AGRICULTURAL UNIVERSITY

Nutrient control method for improving eating quality of rice in saline-alkali land

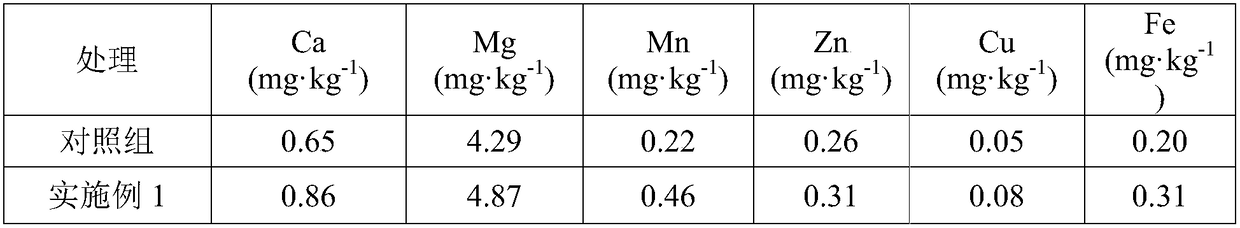

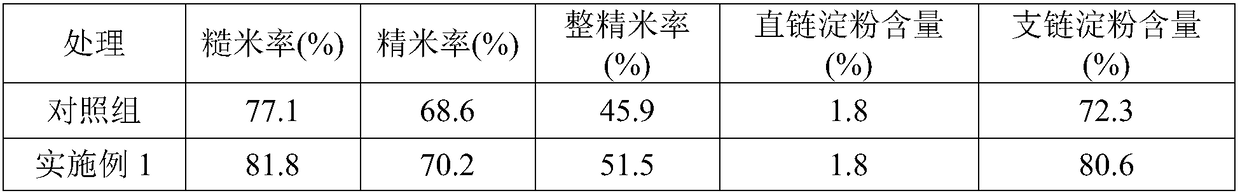

ActiveCN110547162AAvoid exacerbation of salt damageFully absorbedFertilising methodsUrea compound fertilisersAmylaseAgricultural science

The invention provides a nutrient control method for improving the eating quality of rice in saline-alkali land, and relates to methods for cultivating rice in the saline-alkali land. The method aimsto solve the technical problems that existing rice in the saline-alkali land is poor in quality and poor in eating quality. The method includes the steps that 1, a base fertilizer is spread before transplanting; 2, before seedling transplanting, a medium trace nutrient element fertilizer is supplemented as a nitrogen fertilizer before transplanting; 3, a tillering fertilizer is applied after transplanting; 4, a booting fertilizer is applied; 5, a medium trace nutrient element fertilizer is applied on leaf surfaces in the flowering and fruiting stages of the rice, and nutrient control is completed. According to the rice cultured through the method, the brown rice rate is reduced by 1.9-3.1%, the head rice rate is increased by 2.0-13.6%, the protein content of the rice is increased by 14.3-97.1%, the amylase content is increased by 5.5-64.2%, and the taste value is increased by 3.0-10.4%. The method can be applied to the field of rice culture in the saline-alkali land.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

Special sustained-release panicle fertilizer for sweet glutinous rice and preparation method of special sustained-release panicle fertilizer

InactiveCN108218583AIncrease the number of effective spikesQuality improvementCalcareous fertilisersBio-organic fraction processingAdditive ingredientPolyvinyl alcohol

The invention discloses special sustained-release panicle fertilizer for sweet glutinous rice and a preparation method of the special sustained-release panicle fertilizer, and relates to the field ofagricultural fertilizer. The special sustained-release panicle fertilizer for the sweet glutinous rice is provided base on the basis of the problems that existing fertilizer cannot meet the nutrient demands of the sweet glutinous rice, the release cycle of the fertilizer is short, the yield of fragrant rice is low and the content of aroma effective ingredients in the fragrant rice is low. The special sustained-release panicle fertilizer for the sweet glutinous rice is prepared from the following raw materials in parts by weight: 10 to 30 parts of organic fertilizer, 60 to 80 parts of inorganicfertilizer-trace fertilizer mixed fertilizer, 5 to 10 parts of Chinese herbal medicinal additive, 1 to 3 parts of special fertilizer synergist and 1.3 to 1.5 parts of polyvinyl alcohol; the inorganicfertilizer-trace fertilizer mixed fertilizer consists of inorganic fertilizer and trace fertilizer. The preparation method comprises the steps of preparing and mixing the organic fertilizer, the inorganic fertilizer-trace fertilizer mixed fertilizer, the Chinese herbal medicinal additive and the special fertilizer synergist and granulating. The special sustained-release panicle fertilizer for thesweet glutinous rice, disclosed by the invention, has the advantages that nutrient demands of the sweet glutinous rice at all growth nodes during rice panicle period of the sweet glutinous rice are met, the yield of the sweet glutinous rice is improved, the accumulation amount of nutrient elements is improved, the quality of the sweet glutinous rice is improved, the content of characteristic aroma substances in the sweet glutinous rice is increased and the infection rate of the sweet glutinous rice to pathogenic bacteria is reduced.

Owner:INST OF SOIL & FERTILIZER ANHUI ACAD OF AGRI SCI +1

Processing method of rice

InactiveCN108936253AMoisture controlInhibit fatty acidSeed preservation by irradiation/electric treatmentLipidic food ingredientsWater ChestnutsBud

The present invention discloses a processing method of rice. The processing method comprises the following steps: after un-husked rice is cleaned; the cleaned un-husked rice is subjected to husking; after husked rice separation, a primary microwave treatment is conducted; rice milling, color selecting, polishing and classifying are conducted to obtain a rice primary product; a sophora flower bud extract, a liquorice extract, a water chestnut shell extract, a fresh ginger extract and a honeysuckle extract are added to a sodium alginate aqueous solution to obtain a material A; glacial acetic acid is added to water and stirred evenly; calcium chloride is added to be dissolved; chitosan is added to be stirred evenly; the material A is drop-wise added; the materials are stirred; glutaraldehydeis added to obtain microcapsules; cassia bark essential oil, lemon essential oil, cubeb litsea tree fruit oil, garlic essential oil, eucalyptus globules essential oil, litsea cubeba essential oil andrapeseed polypeptides are added to anhydrous ethanol to obtain a material B; beta-cyclodextrin is added to water for a primary ultrasonic treatment; the material B is added for a secondary ultrasonictreatment; the material B is mixed with bamboo charcoal and the microcapsules; the mixture is sealedly packaged to obtain a preservative bag; the rice primary product is loaded into a polyethylene bagand put in the preservative bag; and electron beam irradiation and secondary microwave treatment are conducted.

Owner:望江县山映米业有限公司

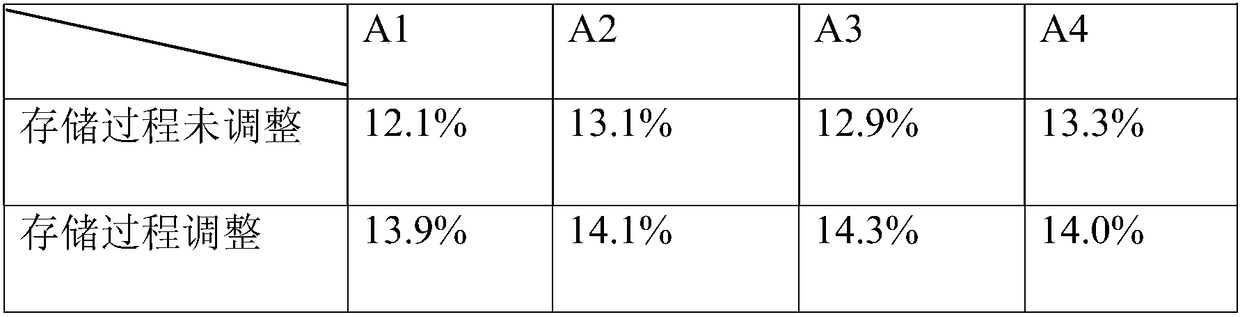

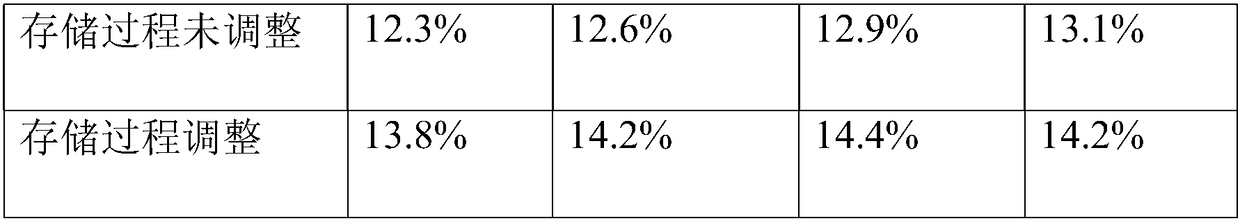

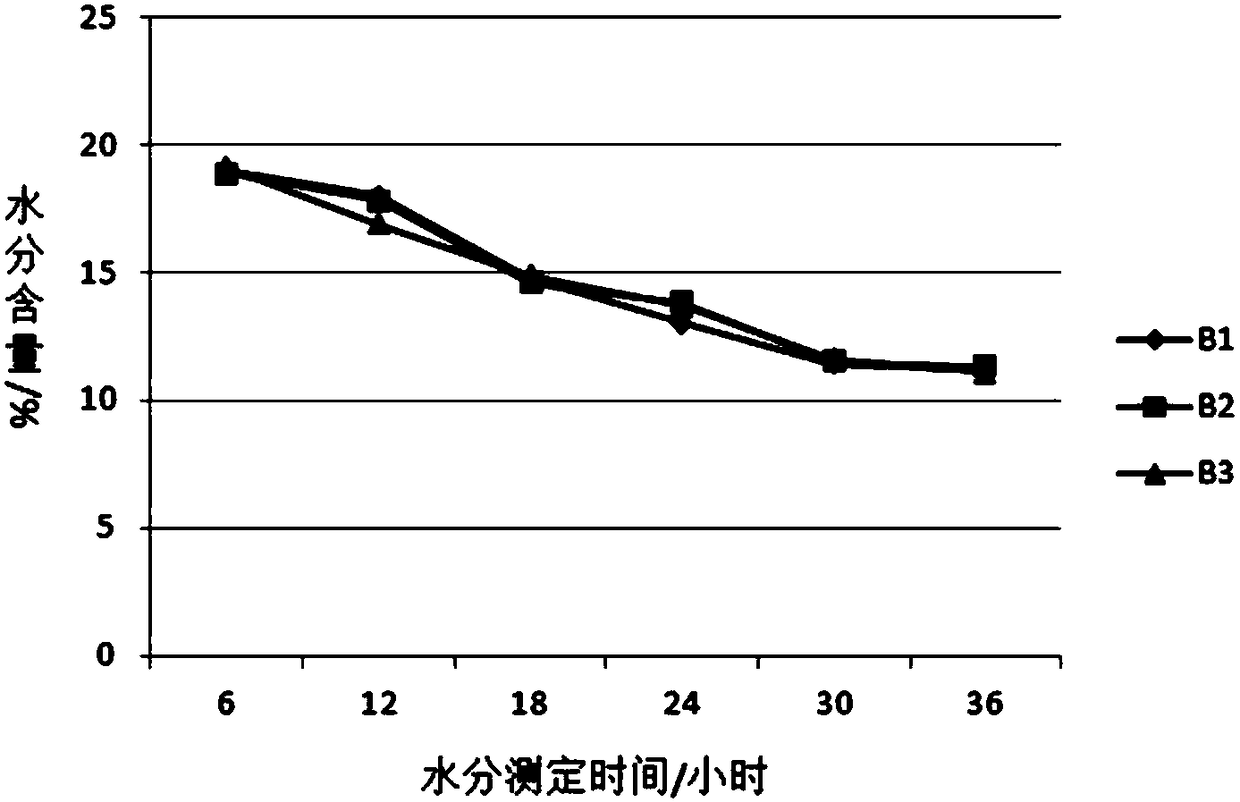

Method for improving head rice rate of rice grains

InactiveCN108554482AImprove the rice polishing rateClimate change adaptationSeed preservation by dryingThreshingRice grain

The invention discloses a method for improving the head rice rate of rice grains. The method comprises the following steps of A, rice harvesting, B, unhusked rice airing and C, warehousing storage. The step A of rice harvesting further comprises the step that a machine is adopted for harvesting, and a micro grain combine-harvester is utilized for harvesting and threshing of unhusked rice. The stepB of unhusked rice airing further comprises the step of evenly paved on the unhusked rice on a cement ground to be aired by sunlight. The step C of warehousing storage further comprises the step thatthe water content of the harvested unhusked rice of the same batch is detected, and when the water content is lower than 14%, the unhusked rice is put in a refrigeration house to be stored. Accordingto the method, through different storage time limits and storage conditions and the influence of the head rice rate of the unhusked rice, the storage temperature and humidity parameters are determined, a time limit and temperature and humidity combined adjustment scheme for a large quantity of unhusked rice is formed, and the head rice rate of the unhusked rice is improved.

Owner:青岛袁米农业科技有限公司

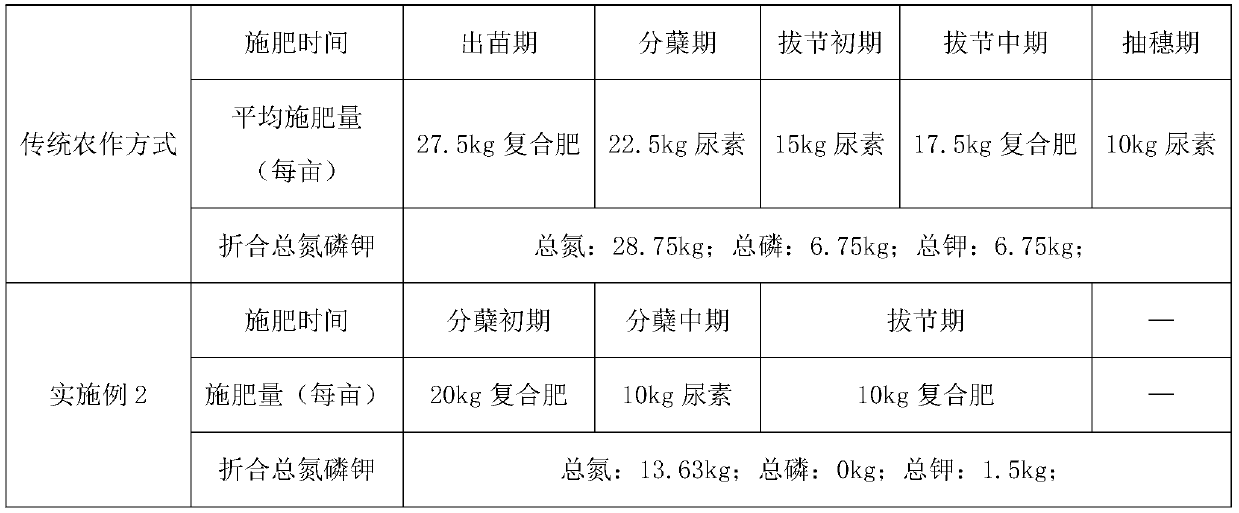

Hulled rice conditioning method under vacuum state

The invention provides a hulled rice conditioning method under a vacuum state. A hulled rice vacuum-conditioning technology is characterized in that hulled rice is subjected to comprehensive processing of dampening and infiltrating by hydrothermal functions and certain infiltrating time. On the basis that an original rice milling technology and equipment is not changed, a hulled rice vacuum-conditioning working procedure is added in the original technology before clean hulled rice subjected to grain and hulled rice separation enters a first rice husking machine between working procedures of hulling and rice husking for hulled rice conditioning. The hulled rice (of which the moisture content is 12.5%) is taken as a raw material, the hulled rice is conditioned in vacuum environment to research an influence rule to a head rice rate by vacuum conditioning time, a vacuum degree and humidification capacity in different vacuum conditioning control parameters, and test conditions are further optimized by response surface analysis on the basis of a single factor test. A result shows that optimal vacuum conditioning parameters are as follows: the vacuum conditioning time is 30min, the vacuum degree is 40kPa, the humidification capacity is 1.6%, and at the time, the head rice rate is about 72.54%.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Breeding method of special japonica rice restorer for beer

The invention discloses a breeding method of a special japonica rice restorer for beer, and belongs to the technical field of special rice breeding. According to the method, a japonica rice strain which is high in head rice rate, short, round and high in yield, a japonica rice strain low in gelatinization temperature, an indica rice strain with which is high in restoring capacity, good in matchingperformance, loose in rice starch distribution and high in amylase content, and a high-yield, disease-resistant and cold-resistant japonica rice strain serve as parents, and through scientific hybridization matching and target trait screening, the high-yield, cold-resistant, disease-resistant, short rounded grain special beer japonica rice restorer with the high head rice rate, the low gelatinization temperature, the loose starch distribution, the high rice amylase content and the good matching performance is bred. The restorer or hybrid rice matched with the restorer can be used for beer brewing, and the economic income can be increased by 500 yuan or above per mu for farmers in the planting process. The method is scientific, efficient and easy to operate, and plays a certain role in breeding of special rice varieties.

Owner:FUJIAN AGRI & FORESTRY UNIV

A kind of high temperature resistant rice plant growth regulator and its use method and application

ActiveCN110663691BReduce heat damageIncrease productionBiocidePlant growth regulatorsBiotechnologyPlant hormone

The invention discloses a high-temperature-resistant rice plant growth regulator and its use method and application, belonging to the field of promoting plant growth. The active ingredients of the regulator include abscisic acid and sucrose. When used, the concentration of the abscisic acid is 1-100 μmol / L, the sucrose accounts for 0.1-2.5% of the total mass of the regulator. The present invention is based on the influence of the interaction between the natural plant hormone abscisic acid and the natural sugar substance sucrose on the grain growth of rice after flowering, and screens the optimum application concentration to significantly reduce the high temperature damage of rice, significantly increase rice yield, and improve rice quality. significantly improved.

Owner:CHINA NAT RICE RES INST

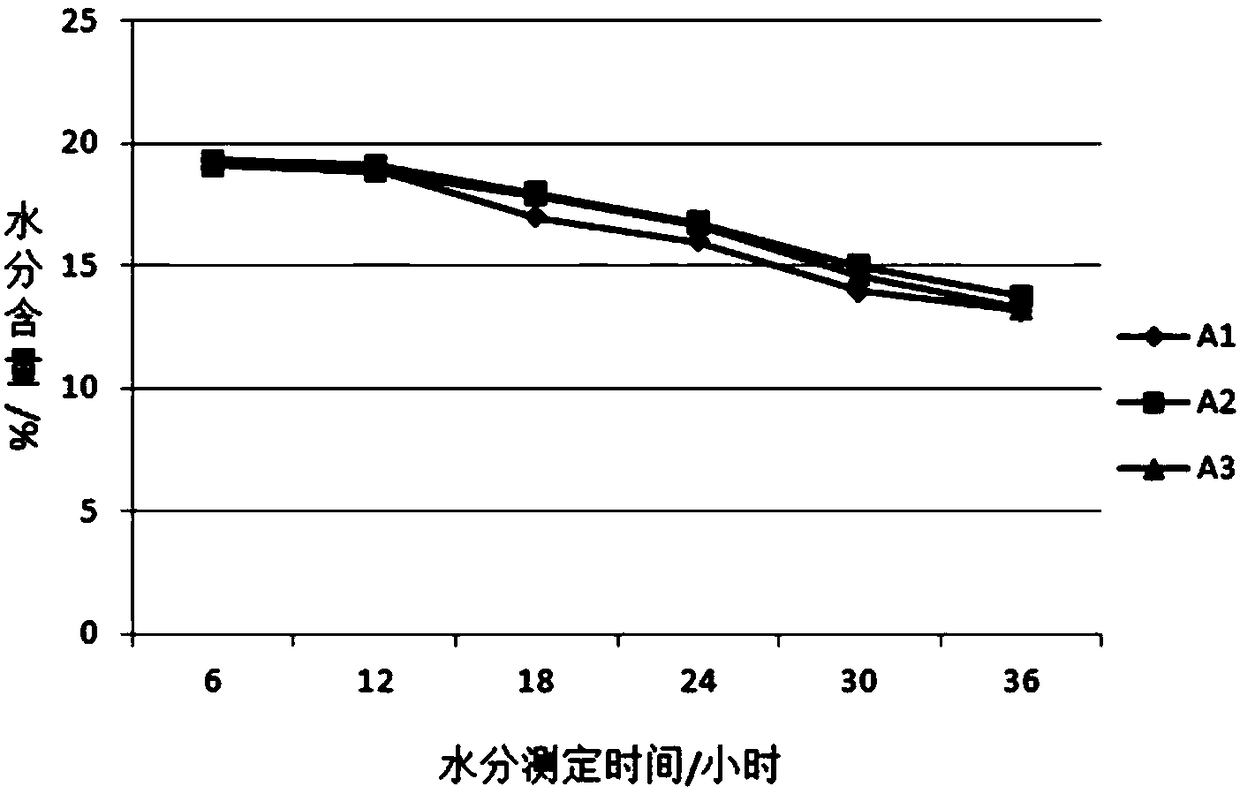

Airing method for increasing head rice yield of rice

InactiveCN108260664AImprove the rice polishing rateReduce moisture contentFood processingClimate change adaptationEngineeringTemperature difference

The application of the invention discloses an airing method for increasing head rice yield of rice. The airing method comprises the following steps of selecting cement ground which is thoroughly cleaned, and spreading a sorghum mat on the clean cement ground as the airing ground. The airing method further comprises an airing manner that a black sunshade cloth is used for shielding aired rice outdoors on daytime, before sunset in the afternoon, the aired rice is loaded into woven bags, and the woven bags are taken indoors. The airing method further comprises the step of uniformly spreading therice on the sorghum mat from 9:30am every day, and the sunshade cloth is used for shielding the aired rice; and the airing method further comprises the step of turning over the aired rice once at 11am. and turning over the aired rice once at 14pm. every day. According to the airing method disclosed by the invention, the rice is moved indoors at night, so that the temperature difference between theairing temperature on the daytime and the temperature at night is reduced, the crack rate is reduced, and the head rice yield is increased; and the situation that sun shielding airing treatment is related with the head rice yield of the rice is guaranteed, and the smaller the change of airing temperature is, the higher the head rice yield of the rice is.

Owner:袁米农业科技有限公司

Wheat-rape interplanting rice planting method without symbiotic period

InactiveCN111512909AAvoid abuseAvoid pollutionClimate change adaptationWatering devicesNutritionPhosphate fertilizer

The invention provides a wheat-rape interplanting rice planting method without a symbiotic period. According to the planting method, through leaving stubble and returning straw to the field, the environmental pollution problem caused by straw burning is solved, and a fertilizer can be saved; a destructive herbicide is sprayed by an unmanned aerial vehicle to directly act on weeds, and thereby theproblem that the herbicide cannot penetrate straw to directly act on weeds is solved; fertilization is performed at the tillering stage and jointing stage, and the fertilization frequency is reduced while the normal growth of rice is met; and a surplus phosphate fertilizer which is not dissolved in water yet in the previous crop wheat-rape field is made full use, the phosphate fertilizer is further dissolved in water in the rice field to provide nutrition for the rice, no phosphate fertilizer is applied during the fertilization process, the abuse of phosphate fertilizers, and the caused phosphorus pollution are effectively prevented, and the labor cost and production cost are reduced by reducing the fertilization frequency and the fertilization amount.

Owner:扬州抱朴自然农业技术有限公司

Enzymatic pretreatment process for improving milling characteristic of brown rice

InactiveCN102430440BImprove the rice polishing rateReduce energy consumptionGrain millingEconomic benefitsBroken rice

The invention discloses an enzymatic pretreatment process for improving milling characteristic of brown rice. In the enzymatic pretreatment process, before milling of the brown rice, food-grade cellulase solution with certain volume, mass, concentration and pH value is sprayed at certain temperature at intervals according to certain single additive amount so that the water content of brown rice reaches milling requirement, cortical cellulose is partly degraded, and the cortical strength of rice kernels is lowered, thereby further reducing the grinding force needed for milling, decreasing broken rice generated during the milling process and lowering milling energy consumption. The enzymatic pretreatment process has no toxic side effects and is beneficial to the improvement of the economic benefit of rice processing enterprisers.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

A grain circulation dryer based on graphene far-infrared heating and its drying method

ActiveCN113632833BReduce drying energy consumptionDry evenlySeed preservation by dryingInfraredThermodynamics

The invention discloses a grain circulation dryer based on graphene far-infrared heating and a drying method thereof. Each adjacent two far-infrared heating components and ventilation and dehumidification components are arranged at intervals up and down, and the grain storage components are arranged along the height direction from top to bottom. Above the first far-infrared heating component, there is a synchronous grain discharge module between the last ventilating and dehumidifying component and the collecting hopper at the bottom; the grain materials in the collecting hopper are conveyed to the elevator through the screw conveyor and the hoist At the top, the grain flow direction controller is used to adjust whether the grain material enters the discharge pipe to be discharged from the dryer or enters the grain storage assembly to be dried again. The present invention is based on the principle that the graphene material emits infrared rays at low temperature after electrification, and the surface temperature of the emission source can be precisely adjusted within the range of 40-80°C, and utilizes the characteristic of being able to directly contact with grain materials to fully improve drying quality and efficiency and reduce production costs.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Spirulina qi-regulating blood-nourishing rice and preparation method thereof

InactiveCN106136083ARich in compositionWith regenerationFood coatingNatural extract food ingredientsFimbristylis miliaceaBasella rubra

Spirulina qi-regulating blood-nourishing rice is made of, by weight parts, 30-45 parts of spirulina phycocyanin liquid, 20-28 parts of astragalus, 23-26 parts of atractylodes lancea, 18-22 parts of blumea, 13-19 parts of basella alba, 12-17 parts of fimbristylis miliacea, 10-15 parts of carthamus tinctorius, 8-13 parts of platycarya strobilacea sieb, 5-9 parts of white hyacinth bean, 4-8 parts of anoectochilus formosanus, 3-6 parts of pen shell ligament, 2-5 parts of daylily root and 700-900 parts of rice. A method for preparing the spirulina qi-regulating blood-nourishing rice mainly comprises a step (1) of preparing rice; a step (2) of preparing spirulina phycocyanin liquid; a step (3) of preparing Chinese medicine liquid; a step (4) of mixing; and a step (5) of drying and sterilization. According to the method, phycocyanin in fresh spirulina is fully extracted, and phycocyanin and the Chinese medicine liquid are evenly mixed and then sprayed on the surface of the rice, so that the rice has rich phycocyanin nutrient and further has pharmacology effects of the selected traditional Chinese medicines in the raw materials and has effects of regulating qi and nourishing blood.

Owner:HARBIN HUAZAO BIOTECH DEV

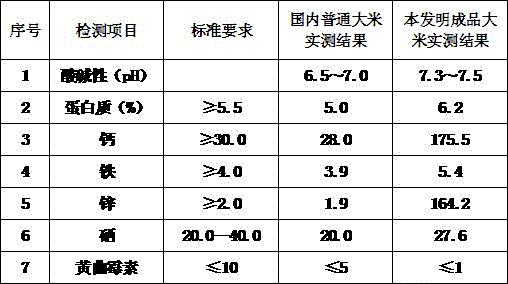

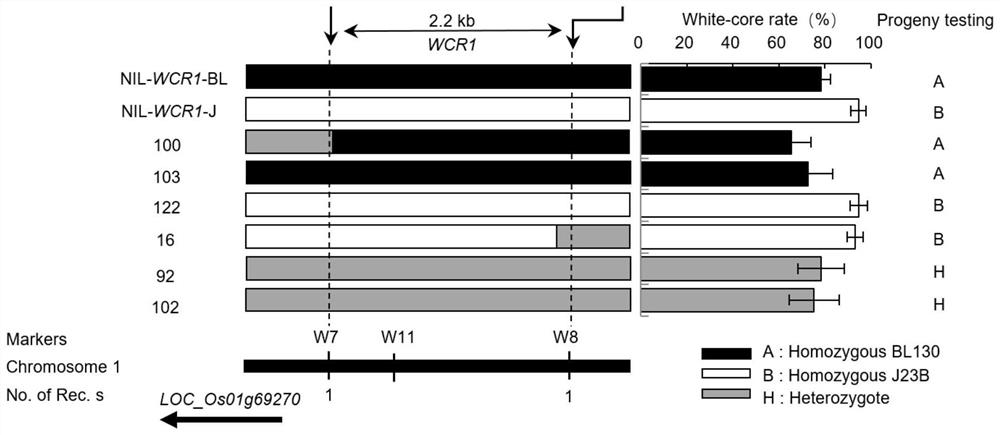

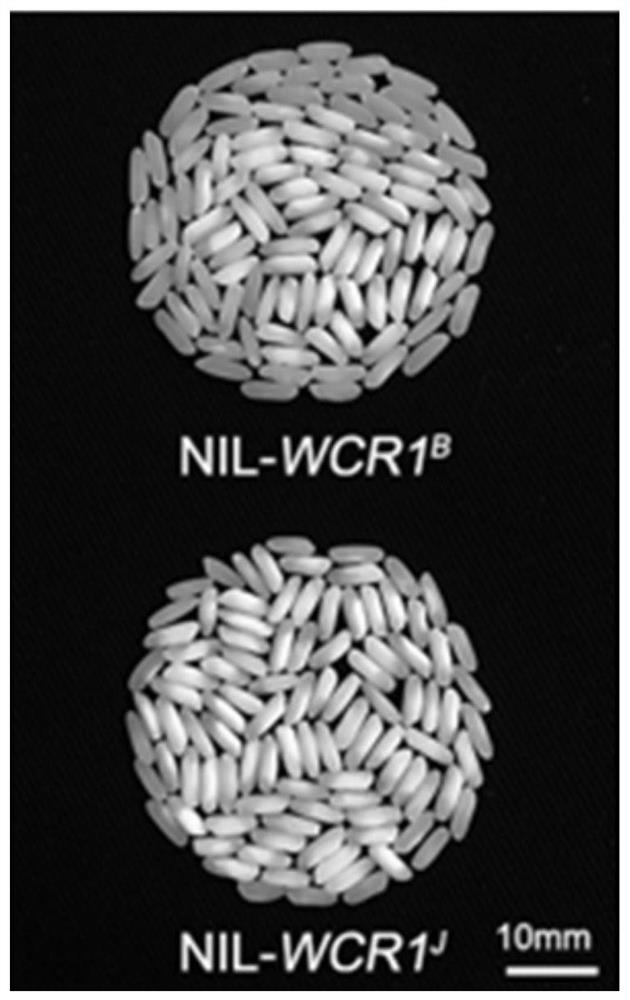

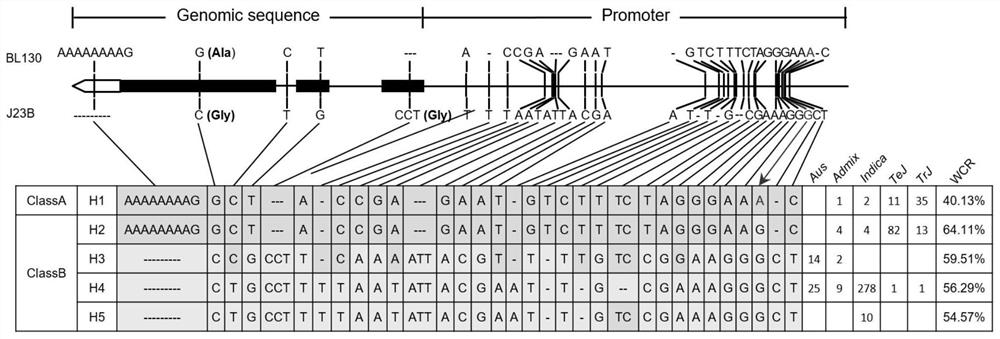

Application of WCR1 gene in regulating core-white rate or taste quality of rice

ActiveCN111808865AEliminate in timeShorten the breeding cycleMicrobiological testing/measurementPlant peptidesBiotechnologyGenetic stock

The invention relates to a new multi-effect core-white-related gene WCR1. A transgenic material is constructed for verification, and finally a functional variation site is found and a corresponding molecular marker is developed, so that an effective theoretical basis and technical support are provided for improvement of chalkiness of rice. The WCR1 gene is used, through genetic manipulation, the core white rate can be reduced by about 20%, the head rice rate can be increased by about 10%, certain positive influences are also achieved on the yield and the taste value of a single plant, and theinfluences are rarely seen in production and application. The invention provides the molecular marker for low core white rate. The detection of the molecular marker can quickly identify a homozygous genotype single plant with low core white rate in the seedling stage, and timely eliminate single plants with high core white rate, so that the production cost is saved, the selection efficiency is greatly improved, and the breeding period of rice varieties is greatly shortened.

Owner:HUAZHONG AGRI UNIV

Method for improving head rice yield of high-quality late indica rice by using radio frequency heating technology

InactiveCN109601616AImprove the rice polishing rateEasy to operateSeed preservation by heatingSeed preservation by dryingRadio frequencyQuality standard

The invention relates to a method for improving the head rice yield of high-quality late indica rice by using a radio frequency heating technology. The method comprises the following steps: (1) high-frequency radio-frequency heating, tempering, low-frequency radio-frequency heating, tempering, and natural cooling. The method of the invention dries high-moisture high-quality late indica rice into arelatively-high-moisture high-quality late indica rice with a moisture content of 16.0-18.0% by the high-frequency radio-frequency heating and the tempering, and then dries relatively-high-moisture high-quality late indica rice into a high-quality late indica rice product with a moisture content of 13.0-13.5% by the low-frequency radio-frequency heating and the tempering. Compared with traditional drying methods, the method of the invention has simple operation and low energy consumption, the head rice yield of the high-quality late indica rice product is as high as 57.0-62.1%, the taste quality is 90-93, and the product is in line with the national primary quality standard of high-quality rice.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY +1

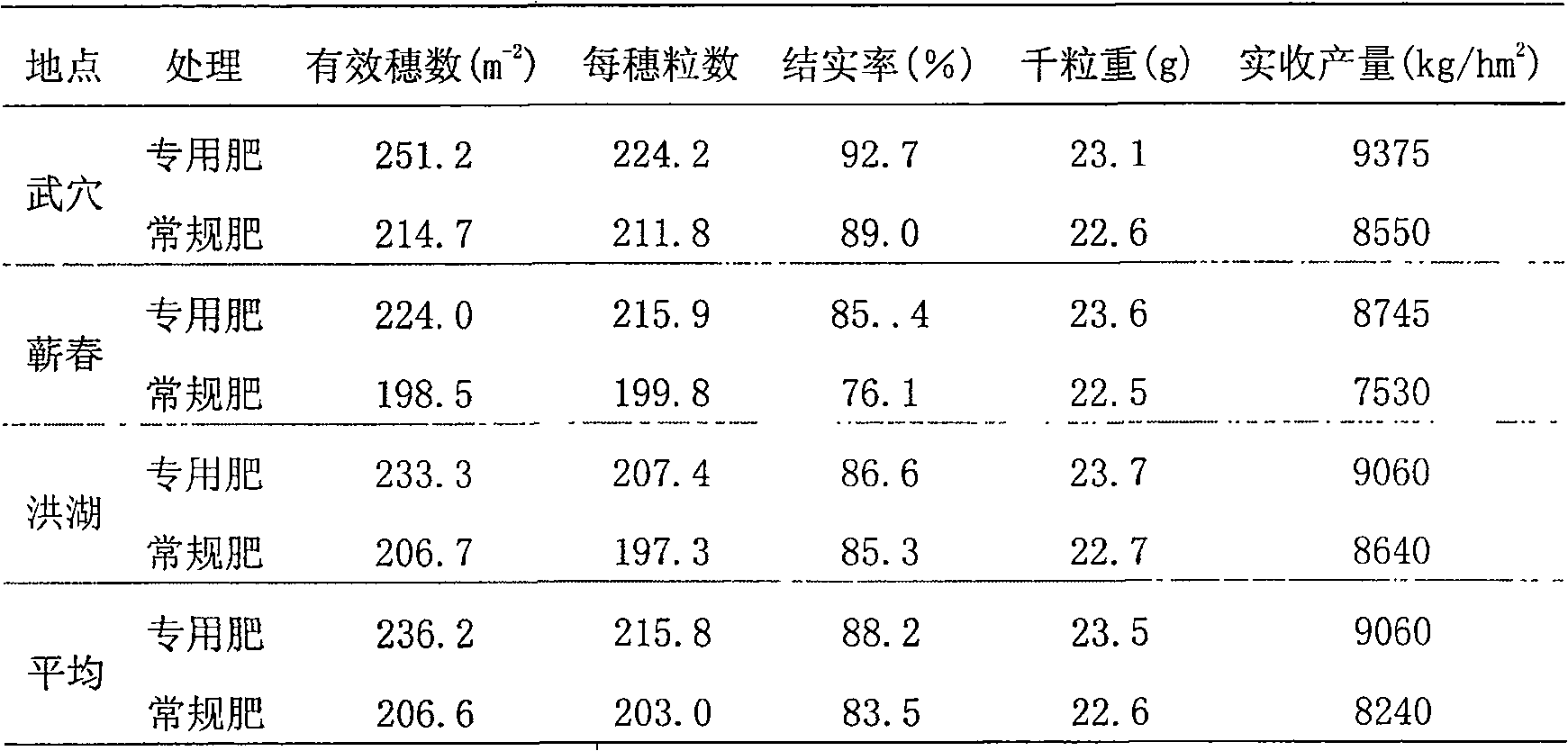

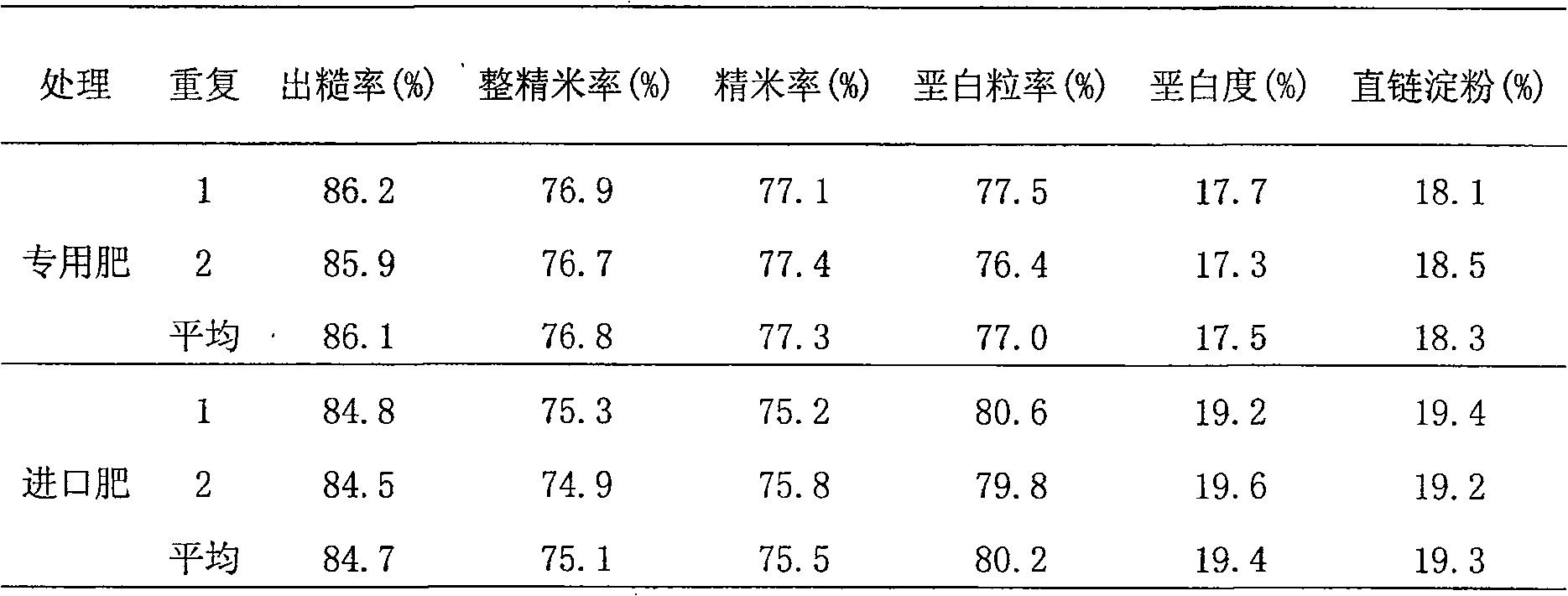

Special formulation fertilizer for rice

ActiveCN100548932CPromote growthIn line with the law of absorptionSuperphosphatesUrea compound fertilisersHectarePotassium

The invention belongs to the technical field of fertilizers, and in particular relates to a special formula fertilizer for rice. It is characterized in that the weight percent of effective elements in the fertilizer in terms of pure nutrients is 25-15 nitrogen, 15-9 phosphorus pentoxide, 20-12 potassium oxide, 5-0 silicon dioxide, 8-0 calcium, and 5-1 sulfur and zinc 2-1. Compared with the prior art, the fertilizer-nutrient distribution ratio of the rice-specific formula of the present invention is reasonable, conforms to the nutrient absorption rule of rice, can obviously promote rice growth, increase rice yield, increase economic benefits, and improve rice nutritional quality. The application test shows that the special formula fertilizer for rice of the present invention can increase the yield of rice by 660-820kg per hectare, increase the income by 756-1468 yuan, and the brown rice rate, the whole polished rice rate, and the polished rice rate in the rice processing quality increase by 1.4%, 1.7% and 1.8% respectively. The white kernel rate and chalkiness decreased by 3.2% and 1.9% respectively, and the amylose content decreased by 1.0%. At the same time, fertilizer use efficiency increased by 5.1%-13.8%.

Owner:HUBEI YISHIZHUANG AGRI TECH

Early and medium maturing rice planting method

InactiveCN109997633AStrong disease resistanceImprove the rice polishing rateRice cultivationRice plantsOryza sativa

The invention relates to the technical field of agricultural cultivation, in particular to an early and medium maturing rice planting method. Rice is generally planted in southern China, and rice planted in northern China is poor in disease resistance and low in head rice rate. The early and medium maturing rice planting method includes: 1) rice breeding, to be specific, planting a plurality of individual plants 'Qiuyou 88' in a cultivation rice field, and selecting a prominent strain for generation-adding breeding; 2) planting the bred rice; 3) fertilizing in a whole growth period; 4) retaining water in a tillering stage, retaining water from ear development to an earing stage, controlling water from a tillering termination stage to an ear differentiation starting stage, and performing dry and wet combined water control in a grain-filling stage; 5) spraying isoprothiolane in the middle of July, and spraying isoprothiolane after earing. High disease resistance and high rice rate are realized.

Owner:宁夏金灵州种业有限公司

A control method and device for feeding and discharging materials in a rice milling chamber

ActiveCN106311381BImprove work efficiencySafe and reliable workGrain treatmentsWorking pressureEngineering

The invention discloses a control method and device for rice milling chamber feeding and discharging. The control method includes the steps of (a) early-stage preparation, (b) traction rod position adjustment, (c) rice milling chamber feeding and discharging pre-commissioning, (d) rice milling chamber allocation adjustment, (e) rice milling chamber feeding and discharging regulation and control, and (f) hydraulic device working pressure adjustment. The device comprises a rice milling chamber and control mechanisms. A rice feeding movement valve is arranged at one end of the rice milling chamber, and a rice discharging movement valve is arranged at the other end of the rice milling chamber. Each control mechanism comprises a workbench, a hydraulic device and a traction mechanism. Each hydraulic device is provided with a pushing rod. Each traction mechanism comprises a traction base and a traction rod. The pushing rods are connected with the corresponding traction bases. By means of the control method and device, a feeding inlet meeting the size requirement of rice species and a discharging outlet meeting the size requirement of the rice species are started according to the categories of specific rice species, so that the sizes of the inlet and the outlet are effectively controlled, time and labor are saved, rice losses are reduced, and the head rice rate is increased. The control effect of the device is good, moreover, the control process can be completed only through two persons, and cost is reduced.

Owner:麦稻智慧粮食有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com