A grain circulation dryer based on graphene far-infrared heating and its drying method

A cyclic drying, far-infrared technology, applied in the direction of preservation of seeds by drying, can solve the problems of uneven drying, waste heat and exhaust gas emission, slow drying rate, etc., achieve uniform drying and high quality, improve the rate of finishing rice, and dry energy consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention are described in detail below, but the protection scope of the present invention is not limited to the embodiments.

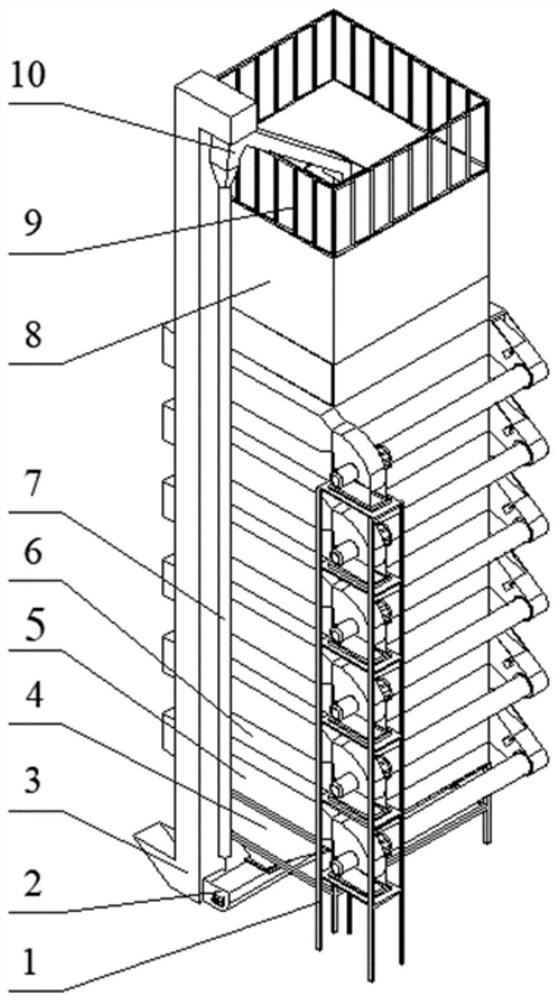

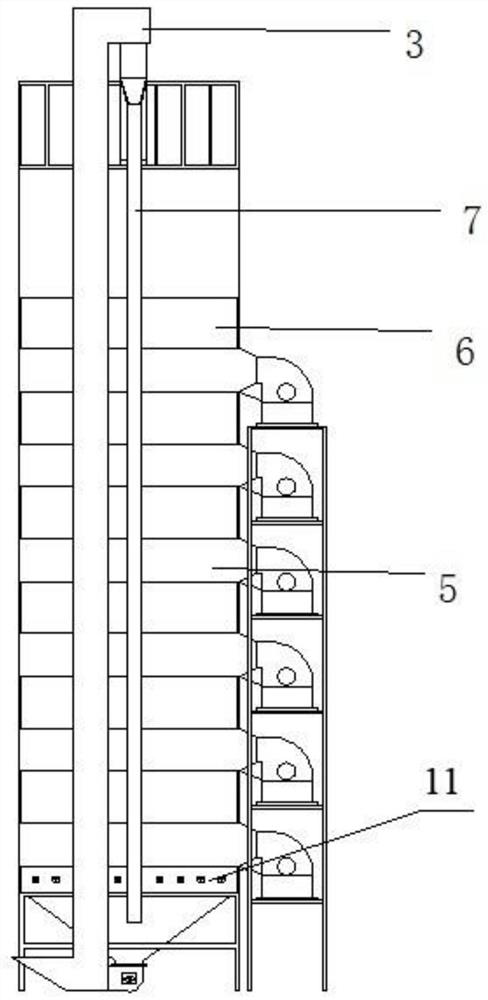

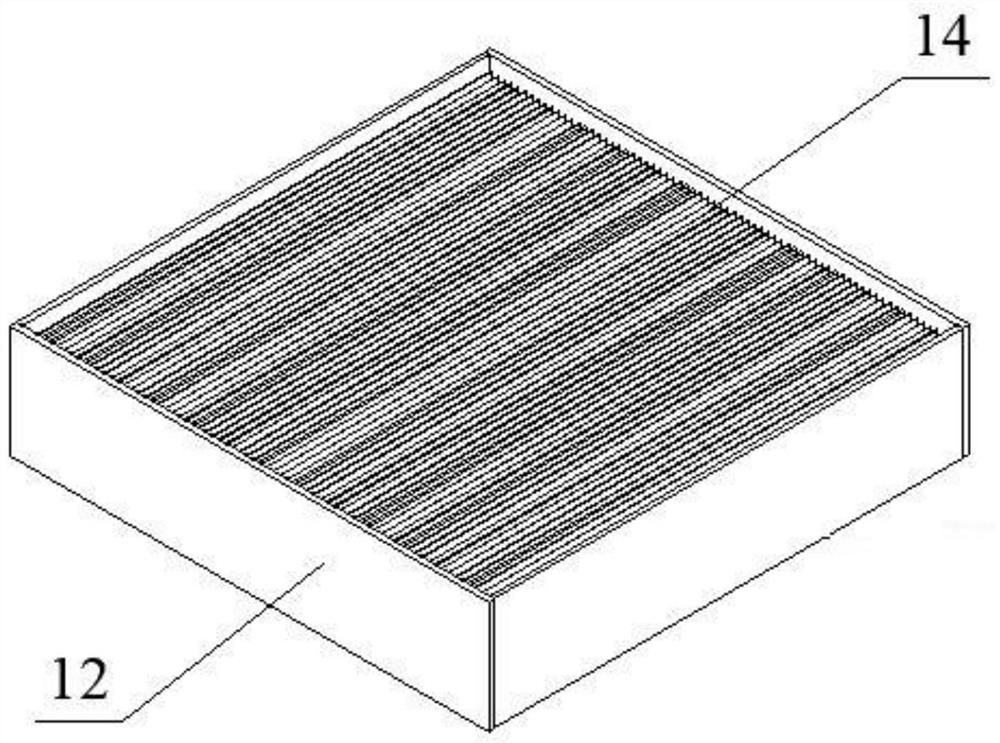

[0038] like figure 1 As shown, a kind of grain circulation dryer based on graphene far-infrared heating of the present embodiment includes a hoist 3, a grain storage assembly 8, a collection hopper 4, a screw feeder 2, a number of far-infrared heating assemblies 6 and a ventilation exhaust. Wet assembly 5; every two adjacent far-infrared heating assemblies 6 and ventilation and dehumidification assemblies 5 are arranged at intervals up and down, and the grain storage assembly 8 is arranged above the first far-infrared heating assembly 6, and the last ventilation and dehumidification assembly 5 and its A synchronous grain discharge module 11 is arranged between the collecting hoppers 4 at the bottom; the grain materials in the collecting hopper 4 are conveyed to the top of the elevator 3 through the screw f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com