A control method and device for feeding and discharging materials in a rice milling chamber

A control method and material feeding and discharging technology, which is applied in grain processing, agriculture, application, etc., can solve the problems of uncontrolled machine feeding, complicated and time-consuming various orifice plates, difficult control of rice precision, etc., to achieve cost saving and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Preparations for construction:

[0030] 1. Technical preparation: Select equipment with specified specifications according to the characteristics of the present invention, and understand the installation technical requirements between related equipment.

[0031] 2. Labor force preparation: According to the control process and control device, reasonably arrange the operators to carry out the work, and do a good job in the safety technical work before the job, and do a good job in safety technology disclosure.

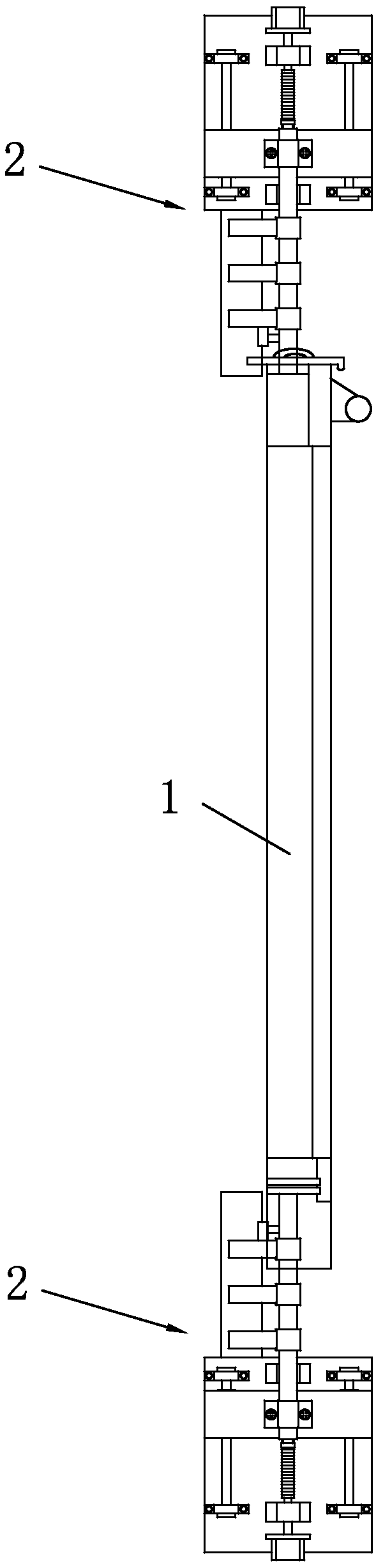

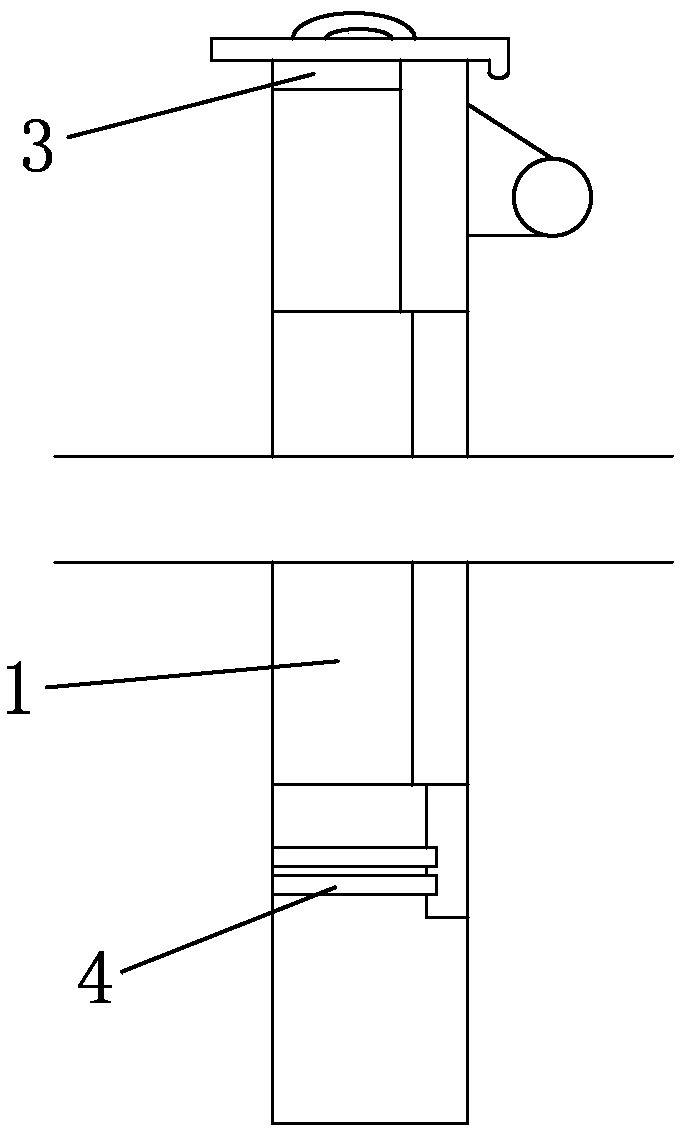

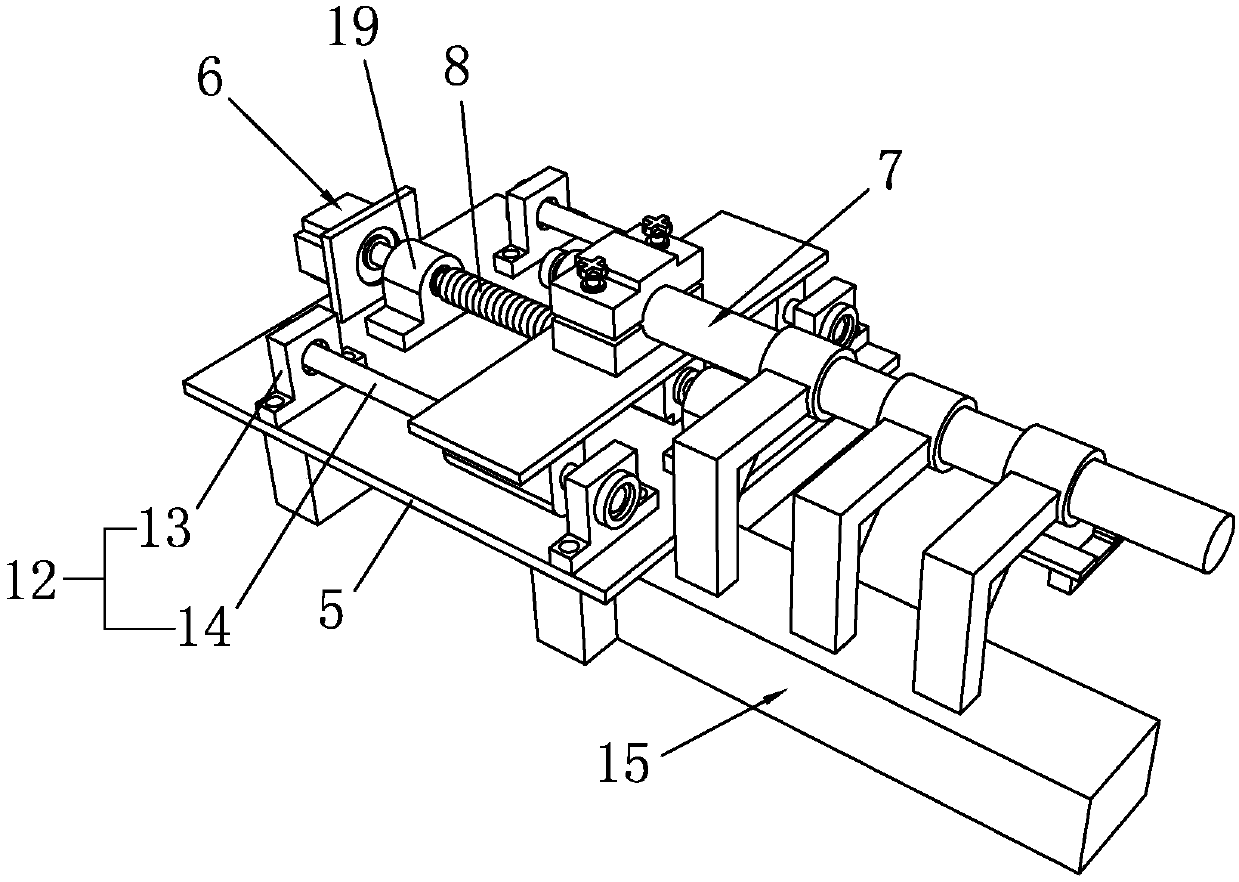

[0032] Such as Figure 1 to Figure 5 As shown, a control method for feeding and discharging materials in a rice milling room includes the following steps:

[0033] (a) Preliminary preparation: Adjust the traction mechanism set at the feeding and discharging places of the rice milling room to the original position, then apply lubricating oil on the traction mechanism and guiding device, and check the hydraulic oil in the hydraulic device, the lubricating oil used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com