Paddy yield increasing cultivation method using acoustic wave treatment

A sonic wave and paddy technology, applied in the field of paddy production increase cultivation method, can solve problems such as difficult large-scale popularization and application, complex treatment methods, cumbersome operation, etc., and achieve the effects of improving rice quality, prolonging photosynthetic time, and enhancing photosynthetic intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

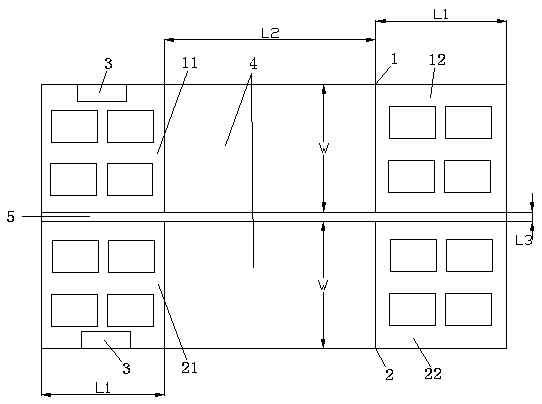

[0025] 1) Select a field with soft and fertile soil, few weeds and no disease sources, sufficient and clean water source, and convenient irrigation and drainage as the seedling field. Irrigate the seedling field with water and soak the field 15 days before sowing, rotary tillage and stubble removal, flatten the seedling field; Width 1.5m, ditch width 25cm, ditch depth 15cm, prepare the seedling board, then drain and dry the board to make the seedling board heavy; 1 day before the sowing date, clear the ditch again, and further level the seedling board; before sowing, put the rice seeds in the sun Turn over and dry for 2 days to increase the germination rate and germination potential of rice seeds; when soaking the seeds, pour the turned seeds into a saline solution with a specific gravity of about 1.13 (50kg of water plus 10kg of salt) for full stirring, remove and float on the salt water The empty seeds and debris, and then wash the remaining plump seeds twice with water; then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com