Enzymatic pretreatment process for improving milling characteristic of brown rice

A technology of pretreatment and brown rice, applied in grain processing, grain milling, application, etc., to achieve the effect of saving energy consumption and safe storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is described in detail with examples below.

[0011] Determination of raw material brown rice initial water content (12.5%), and take by weighing 10kg stand-by.

[0012] A food-grade cellulase solution with a concentration of 100 mg / mL was prepared with pH 5.0 acetic acid-sodium acetate buffer solution, and stored in a refrigerator at 4°C for future use.

[0013] Put the weighed brown rice under the temperature condition of 35°C, and carry out the first enzymatic pretreatment to it, that is, uniformly spray the cellulase solution with a concentration of 100 mg / mL according to the single liquid addition amount of 1.5%, and in this Airtight treatment under the same conditions for 60 minutes; then carry out the second enzymatic pretreatment, that is, evenly spray the cellulase solution at a single dosage of 1.5%, keep the same conditions and keep the airtight treatment for 400 minutes, and then use a rice mill to whiten it.

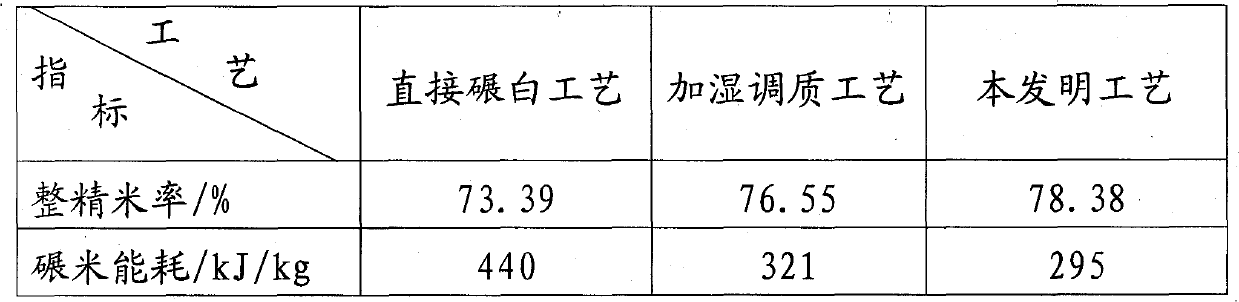

[0014] Table 1 shows tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com