Multifunctional paddy drying device

A drying device and multi-functional technology, applied in drying, dryer, grain drying and other directions, can solve the problems of uneven drying, complicated device operation, etc., so as to prolong the drying time, prolong the storage performance, and reduce the content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

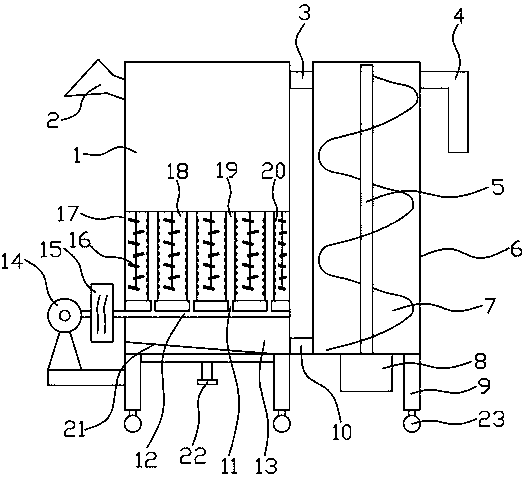

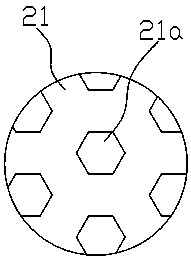

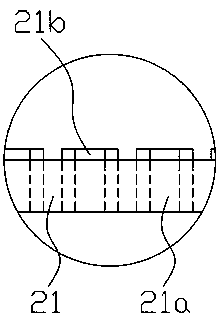

[0023] Such as Figure 1~3 As shown in , 6, the multifunctional rice drying device includes a barn 1, the lower end of the barn 1 is connected with a drying chamber 17, the inside of the drying chamber 17 is provided with a hot air system, and the lower end of the drying chamber 17 is connected with a dry material box 13, One side of the dry material box 13 is connected with a return material box 6, the bottom of the dry material box 13 is provided with a bottom door 22, and the bottom door 22 upper end is obliquely connected with a filter plate 21, and the filter plate 21 surface is provided with a filter hole 21a with an aperture smaller than the rice grain, The upper surface of the filter hole 21a is connected with a sponge ring 21b having the same specifications as the filter hole 21a. The barn 1 is used to temporarily store the rice to be dried, avoiding the need for the operator to dump the rice in real time, which can reduce the labor pressure of the operator. The dryin...

Embodiment 2

[0032] Such as Figure 4 , 5 As shown, this embodiment is a further optimization scheme based on Embodiment 1: at least one guide groove 16a is provided on the surface of the swash plate 16, semicircular bumps 16b are evenly distributed inside the guide groove 16a, and the top of the semicircular bump 16b is connected with Connect to the elastic cord 16c on both sides of the guide groove 16a, the semicircular convex point 16b increases the resistance for the rice to move on the surface of the inclined plate 16, and further prolongs the drying time of the rice. Dry uniformity, due to its own gravity, the rice is subjected to external forces such as the shear force, elastic force, and collision force of the semicircular bump 16b and the elastic rope 16c during the falling process, which induces the generation of free radicals inside the rice, resulting in oxygen free radicals and hydroxyl free radicals. It promotes the oxidative decomposition of fatty acids, produces lipid pero...

Embodiment 3

[0036] Such as Figure 1~6 As shown, the working principle of the present invention is: when the device is drying the rice, the operator adds the rice from the feed port 2 into the barn 1 until the barn 1 is loaded with 75% of the rice of the barn 1 volume, Close the internal switch of the discharge port 4, open the internal switch of the circulation inlet 3, open the air pump 14, the electric heater 15 and the motor 8, and the rice will gradually fall from the inside of the barn 1 to the inclined plate 16 inside the trough 18. Under the action, the paddy slides, rolls and falls downwards on the surface of the inclined plate 16, during which the electric heater 15 heats the air pumped from the air pump 14, and presses the hot air into the inside of the air guide channel 12, and the hot air enters through the air inlet 11 The inside of the hot air pipe 19, and blows from the air outlet 20 to the rice located in the hopper 18, so that the rice is evenly dried, and then the rice ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com