Hulled rice conditioning method under vacuum state

A technology of tempering and brown rice, applied in application, grain processing, grain milling, etc., can solve problems affecting processing and eating quality, reduced rice yield, prone to cracks and broken rice, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

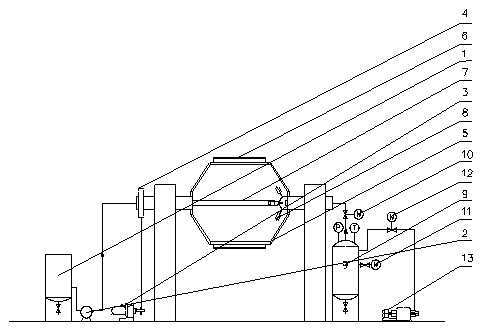

Image

Examples

specific Embodiment approach 1

[0009] Specific implementation mode one: the research on the process parameters of brown rice vacuum conditioning is realized by the following steps: the impact of vacuum conditioning time on the whole polished rice rate, five levels of conditioning time 10, 30, 50, 70, 90min are selected, and brown rice is processed Treatment, under the conditions of vacuum degree of 40 kPa and humidification amount of 1.5%, the change of the whole milled rice rate was measured, and the influence of different tempering time on the whole milled rice rate was studied. The influence of vacuum degree on the rate of whole polished rice, five levels of vacuum degree of 20, 30, 40, 50, 60kPa were selected to treat brown rice. The change of polished rice rate, to study the influence of different vacuum degrees on the polished rice rate. The influence of humidification amount on the rate of polished rice, five levels of humidified amount of 0.5, 1.0, 1.5, 2.0, 2.5% were selected to treat brown rice. ...

specific Embodiment approach 2

[0010] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in the step one, three levels of tempering time 30, 50, and 70min are selected, and under the condition that the degree of vacuum is 40kPa and the amount of humidification is 1.5%, brown rice is processed treatment, and measure the change of the rice polishing rate. Other components and steps are the same as the specific implementation method one.

specific Embodiment approach 3

[0011] Specific embodiment three: the difference between this embodiment and specific embodiment one is that in step one, three levels of vacuum degrees of 30, 40, and 50 kPa are selected, and the vacuum air conditioning time is 30 minutes, and the humidification amount is 1.5%. The unpolished rice was processed, and the change of the polished rice rate was measured. Other components and steps are the same as the specific implementation method one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com