Ice-temperature air adjusting fresh-keeping minced fillet foodstuff and production process thereof

A technology for fresh surimi and food, which is applied in the field of fresh surimi food under ice temperature and air conditioning. It can solve the problems of prolonging the preservation period, easy discoloration of fish balls and fish cakes, and failure to reach them, so as to prevent product discoloration, flavor and taste Maintain good, growth-inhibiting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

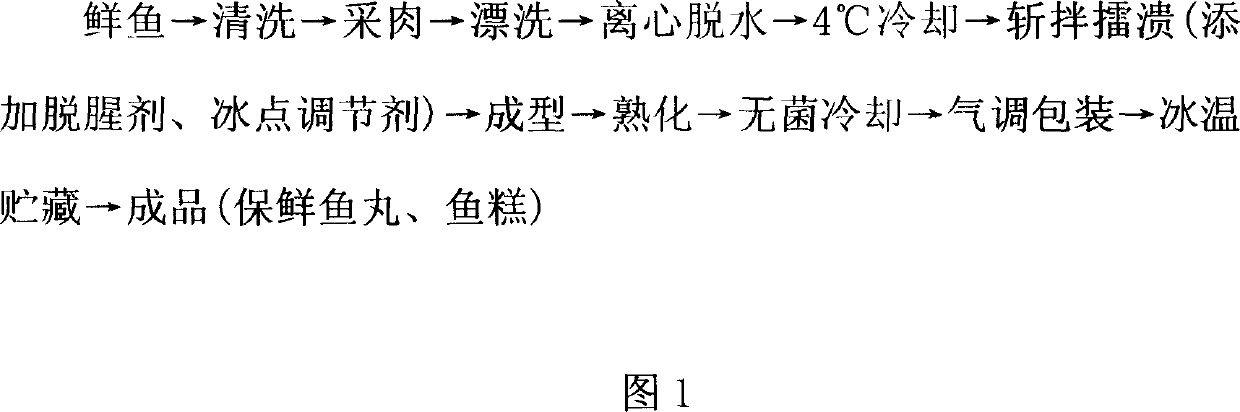

Method used

Image

Examples

Embodiment 1

[0048] Fresh silver carp or grass carp and other freshwater fish are made into surimi through processes such as washing, meat picking, rinsing, and centrifugal dehydration, and then cooled to about 4°C in a high-temperature refrigerator (0-4°C) for later use. Take 50kg of cooled surimi and put it into the cylinder of the crushing machine (cooled by ice water at 0°C) for crushing. After crushing for 20 minutes, add 1.1kg of salt, and after continuing to crush for 20 minutes, add 4.0kg of modified starch esterified tapioca starch Or cross-linked esterified tapioca starch or esterified potato starch or cross-linked esterified potato starch, 0.1kg konjac glucomannan, 0.30kg white sugar, 0.25kg monosodium glutamate, 5.0kg deodorant The proportioning of part is 80-90 parts of ginger juice, 5-10 parts of white pepper, 5-10 parts of edible white vinegar and mix evenly), smash and mix (in this embodiment, do not add water in addition, but utilize fish meat to neutralize and remove The ...

Embodiment 2

[0050] Fresh silver carp or grass carp and other freshwater fish are made into surimi through processes such as washing, meat picking, rinsing, and centrifugal dehydration, and then cooled to about 4°C in a high-temperature (0-4°C) refrigerator for later use. Take 50kg of cooled surimi and put it into the tank of the crushing machine (cooled by ice water, 0°C) for crushing, gradually add 20kg of tap water, add 1.95kg of salt after 20 minutes of crushing, continue to crush for 20 minutes, then add 7.5kg Modified starch esterified tapioca starch or cross-linked esterified tapioca starch or esterified potato starch or cross-linked esterified potato starch, 0.5kg konjac glucomannan, 0.40kg white sugar, 0.30kg monosodium glutamate, 2.5kg deodorant The preparation method of the preparation is 80-90 parts of ginger juice, 5-10 parts of white pepper, and 5-10 parts of edible white vinegar (mixed uniformly) by weight, pounded and mixed. After standing for 30 minutes, it is shaped and h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com