Metal honeycomb type vacuum multi-layer attenuation heat insulation plate

A technology of metal honeycomb and thermal insulation board, which is applied in the direction of metal layered products, layered products, chemical instruments and methods, etc., can solve the problems of large volume, high manufacturing cost, and short life of glass thermos bottles, so as to reduce heat loss and process Easy molding and small thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention:

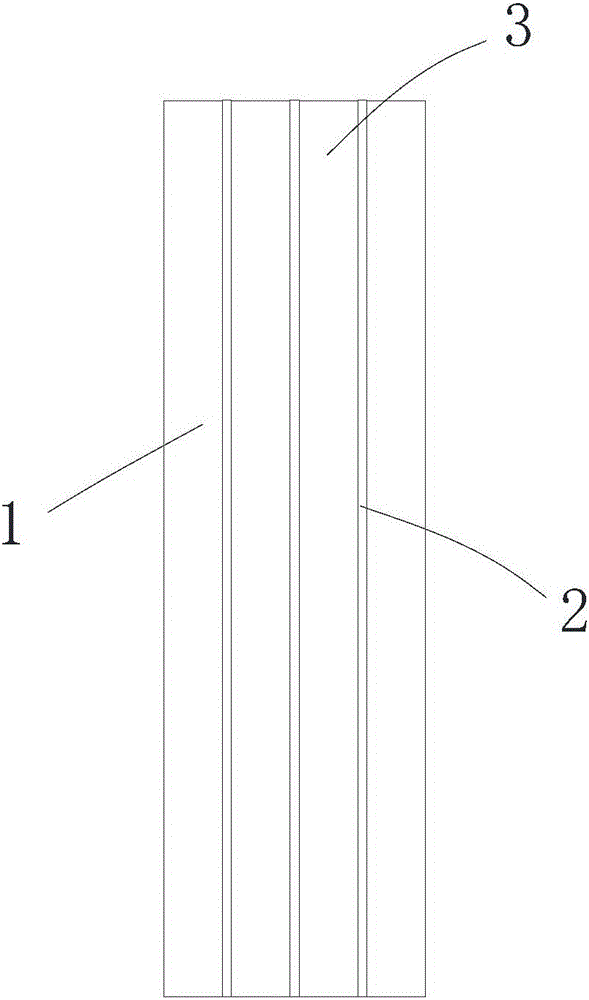

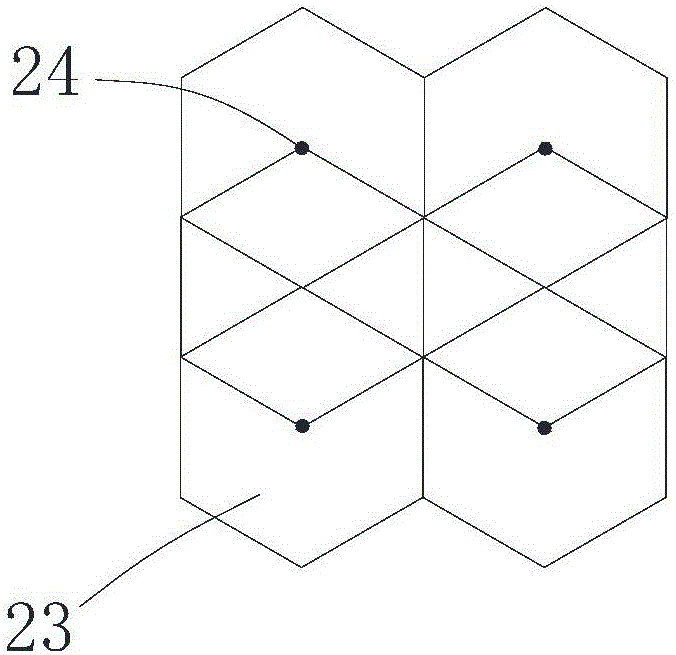

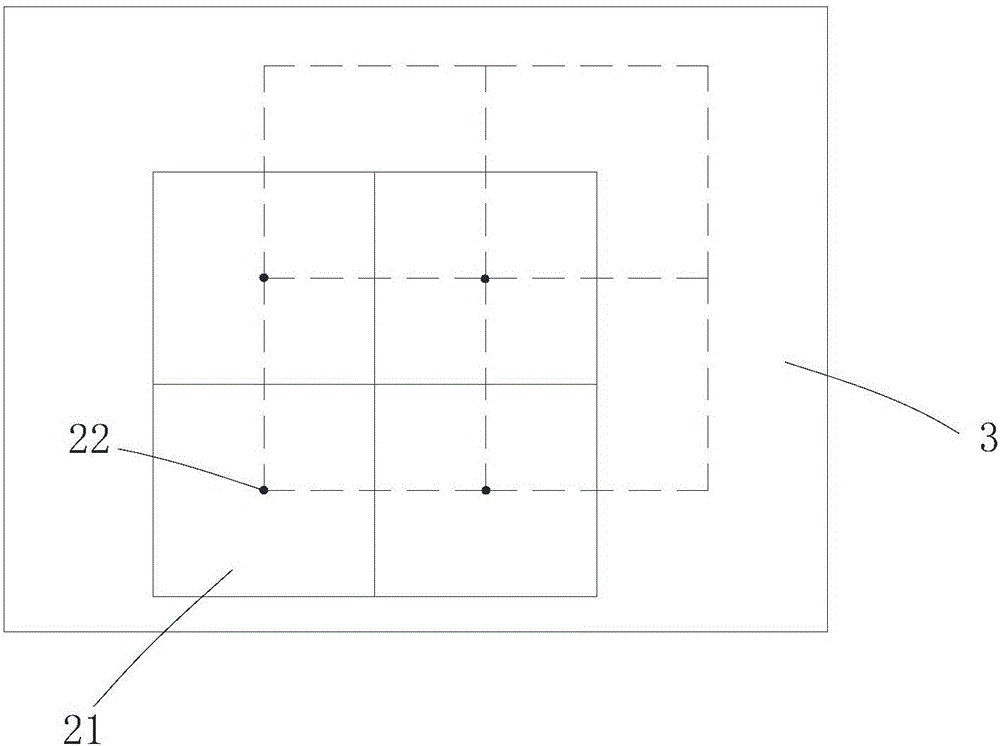

[0021] Such as Figure 1-5 Shown: a metal honeycomb vacuum multi-layer attenuation insulation board with a multi-layer sandwich structure. It mainly includes multi-layer honeycomb panels 2, partitions 3 arranged between the honeycomb chamber panels, and panels 1 wrapped on the outermost side.

[0022] In the combined state, the projections of the side walls of the honeycomb in the multilayer honeycomb chamber plate intersect, and the alloy panel 1, the multilayer honeycomb chamber plate and the partition 3 are fixed by vacuum welding; the honeycomb interior of the honeycomb chamber plate is vacuum, and the single The heat blocking rate of the vacuum honeycomb str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com