Method for sintering neodymium iron boron magnetic tile and spark plasma sintering device thereof

A discharge plasma and sintering device technology, which is applied in the direction of electromechanical devices, circuits, magnetic materials, etc., can solve the problems of low magnetic strength, easy cracking, and slow sintering speed, and achieve magnetic strength and strength improvement, uniform heating, and heating speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

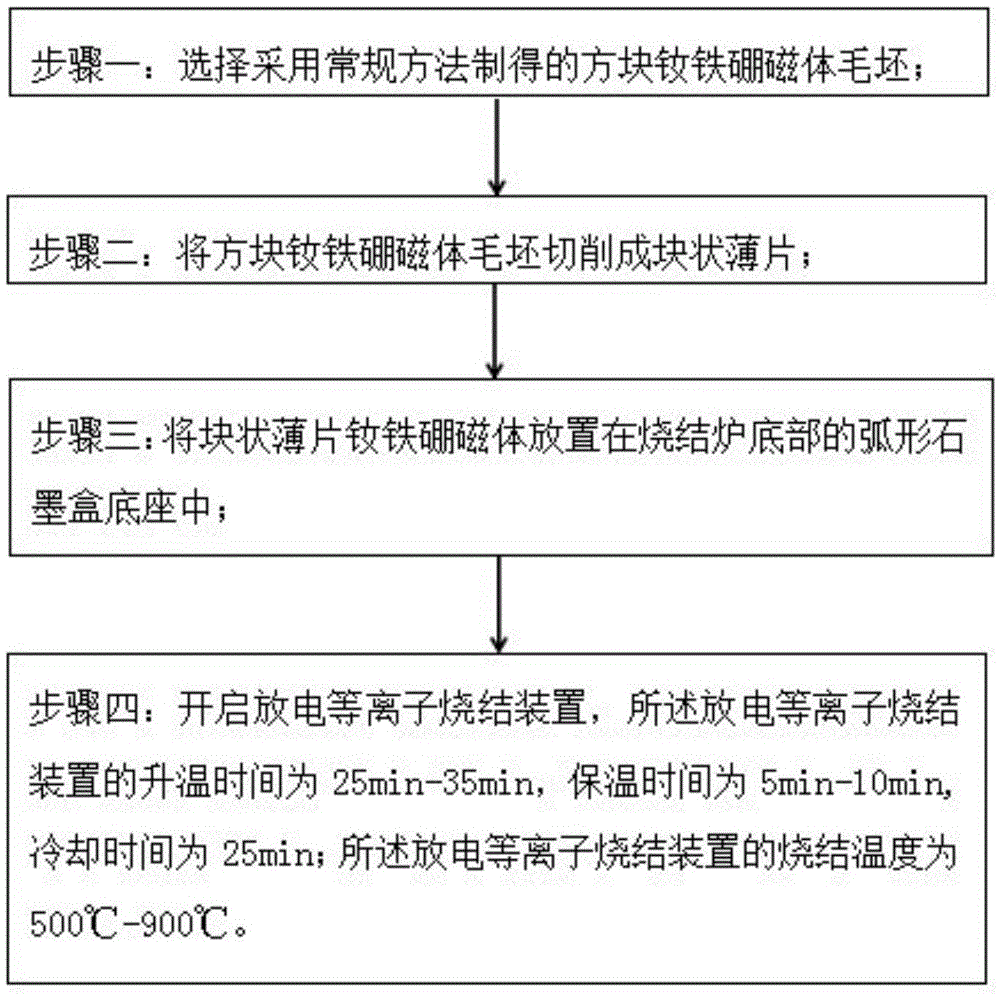

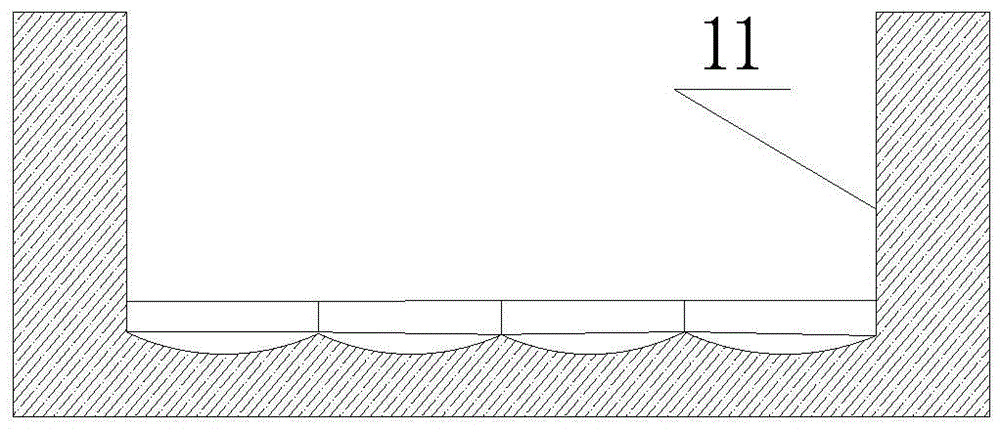

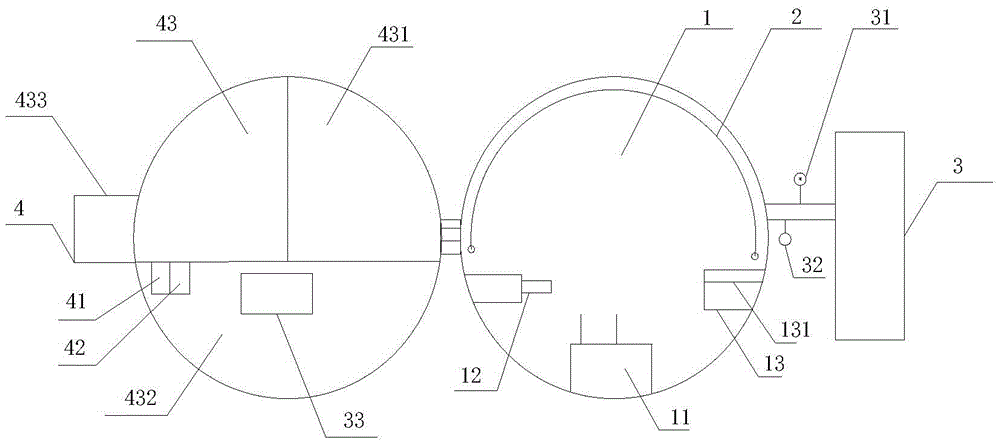

[0042] Such as figure 1 , this specific embodiment discloses a method for sintering NdFeB magnetic tiles, including the following steps:

[0043]Step 1: Select the square NdFeB magnet blank obtained by the conventional method; NdFeB is divided into sintered NdFeB and bonded NdFeB, and the bonded NdFeB has magnetism in all directions and is corrosion-resistant; Because sintered NdFeB is easy to corrode, the surface needs to be plated. Generally, there are galvanized, nickel, environmentally friendly zinc, environmentally friendly nickel, nickel-copper-nickel, and environmentally friendly nickel-copper-nickel. Sintered NdFeB is generally divided into axial magnetization and radial magnetization, depending on the required working surface. As a preference, in this specific embodiment, the square NdFeB magnet blanks are placed in a radial distribution manner, and the field effective magnetic field distribution after installation of the magnetic force lines distributed by the radia...

Embodiment 2

[0050] This specific embodiment discloses a method for sintering NdFeB magnetic tiles. The difference from Example 1 is that the heating time of the spark plasma sintering device is 30 minutes, the holding time is 7 minutes, and the cooling time is 25 minutes. The sintering temperature is 700°C.

[0051] Compared with the magnetic tiles prepared in Example 1, the magnetic force and strength of the magnetic tiles prepared by adopting this specific embodiment are improved.

Embodiment 3

[0053] This specific embodiment discloses a method for sintering NdFeB magnetic tiles. The difference from Example 1 is that the heating time of the spark plasma sintering device is 35 minutes, the holding time is 10 minutes, and the cooling time is 25 minutes. The sintering temperature is 900°C.

[0054] The magnetic strength and strength of the magnetic tile produced by this specific embodiment are equivalent to those of the magnetic tile prepared in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com