Light emitting diode base plate heat radiation structure and manufacture method thereof

A technology of light-emitting diodes and heat dissipation structures, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of poor reflection effect of aluminum plate, weak welding, difficult process technology, etc., and achieve good light reflection effect, flatness and The smoothness is easy to guarantee and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

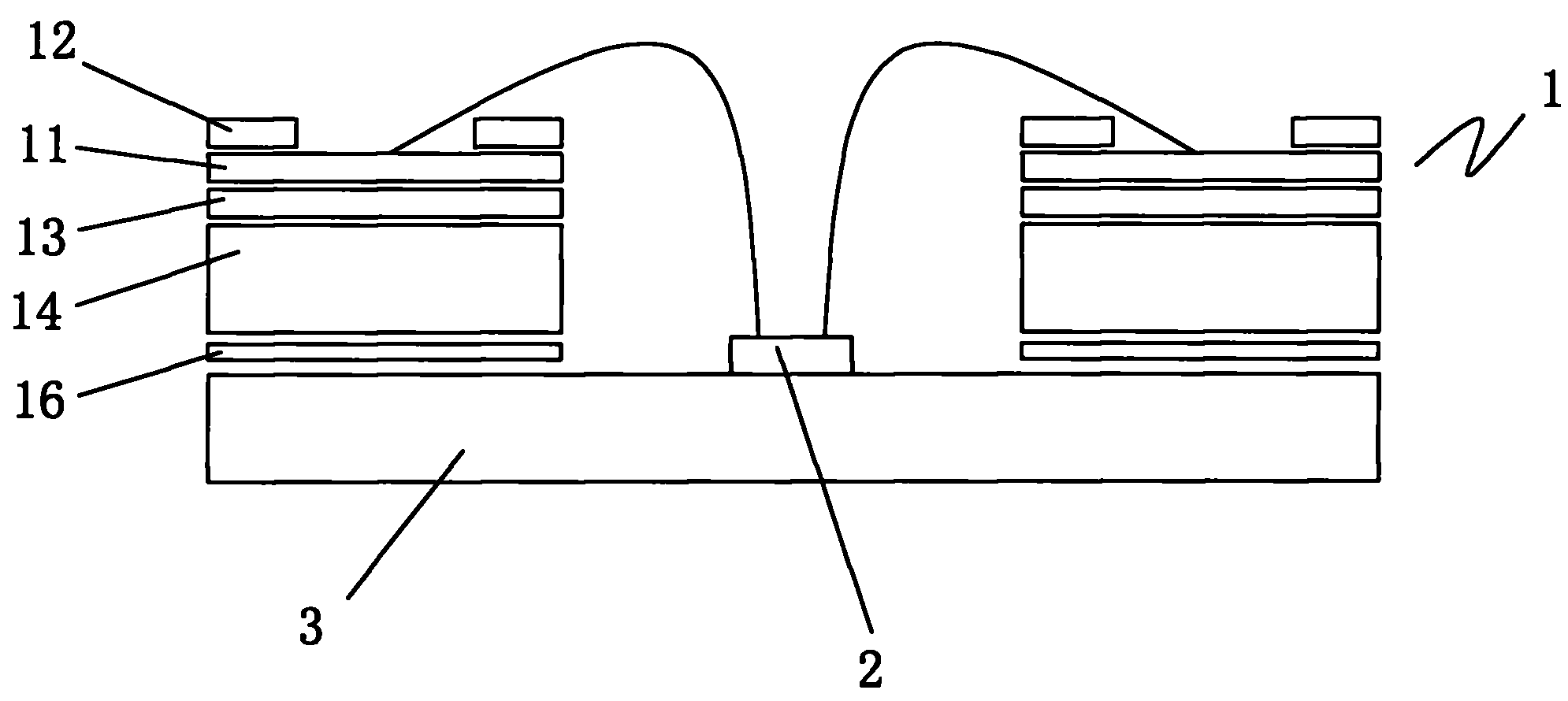

[0026] Embodiment 1: As shown in Figure 3, the heat dissipation structure of the light-emitting diode circuit board disclosed in this embodiment is an improvement on the heat dissipation structure of the conventional light-emitting diode aluminum substrate, which is consistent with the conventional aluminum substrate. The aluminum substrate 1 consists of White oil layer 12 , conductive circuit layer 11 , insulating layer 13 and aluminum substrate 14 .

[0027] Compared with the existing aluminum substrate, the biggest improvement of the aluminum substrate in this embodiment is that the bottom of the aluminum substrate 14 is closely pasted with a heat-dissipating base plate 3 through the heat-conducting adhesive 16, and the material of the base plate 3 can be good for heat dissipation The metal, silicon or ceramics can also be used. A through hole 15 is opened at the position where the light emitting diode 2 is installed on the substrate 14 , the light emitting diode 2 is close...

Embodiment 2

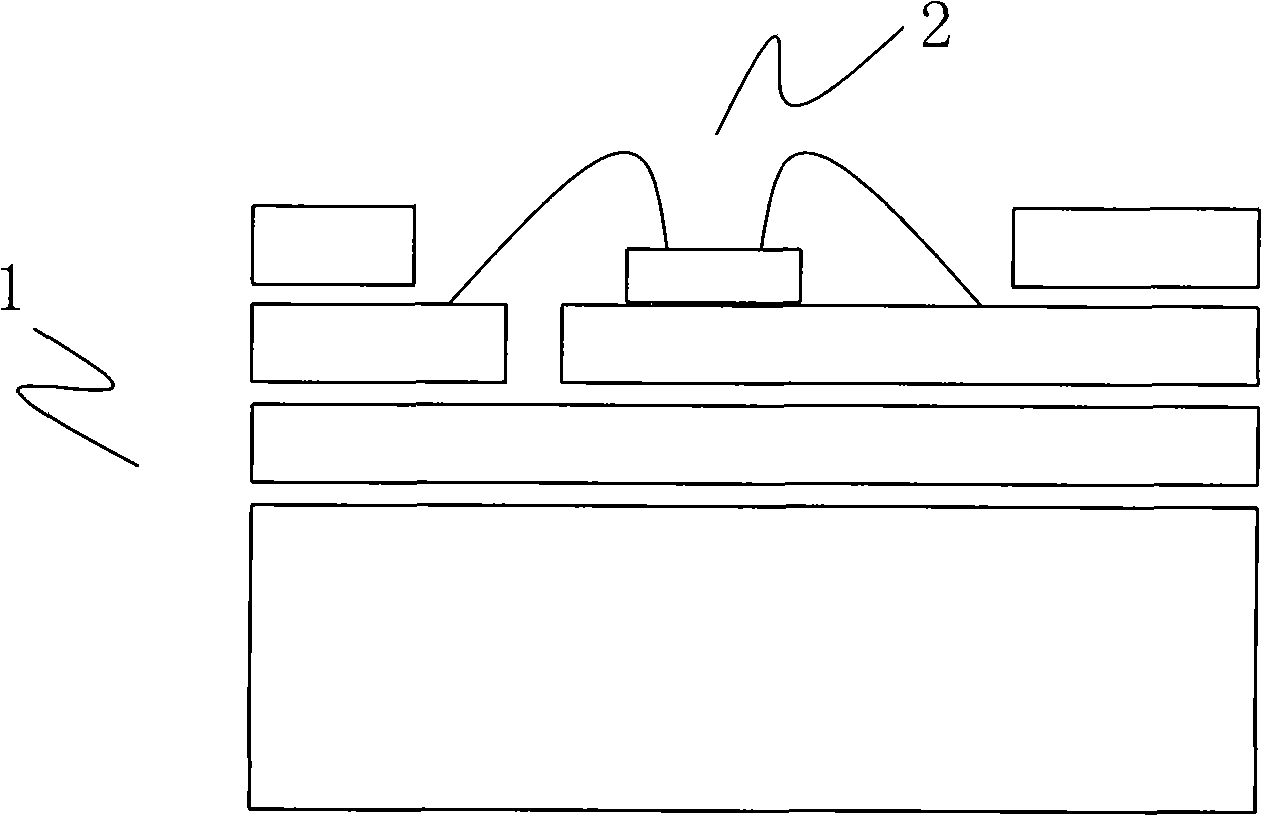

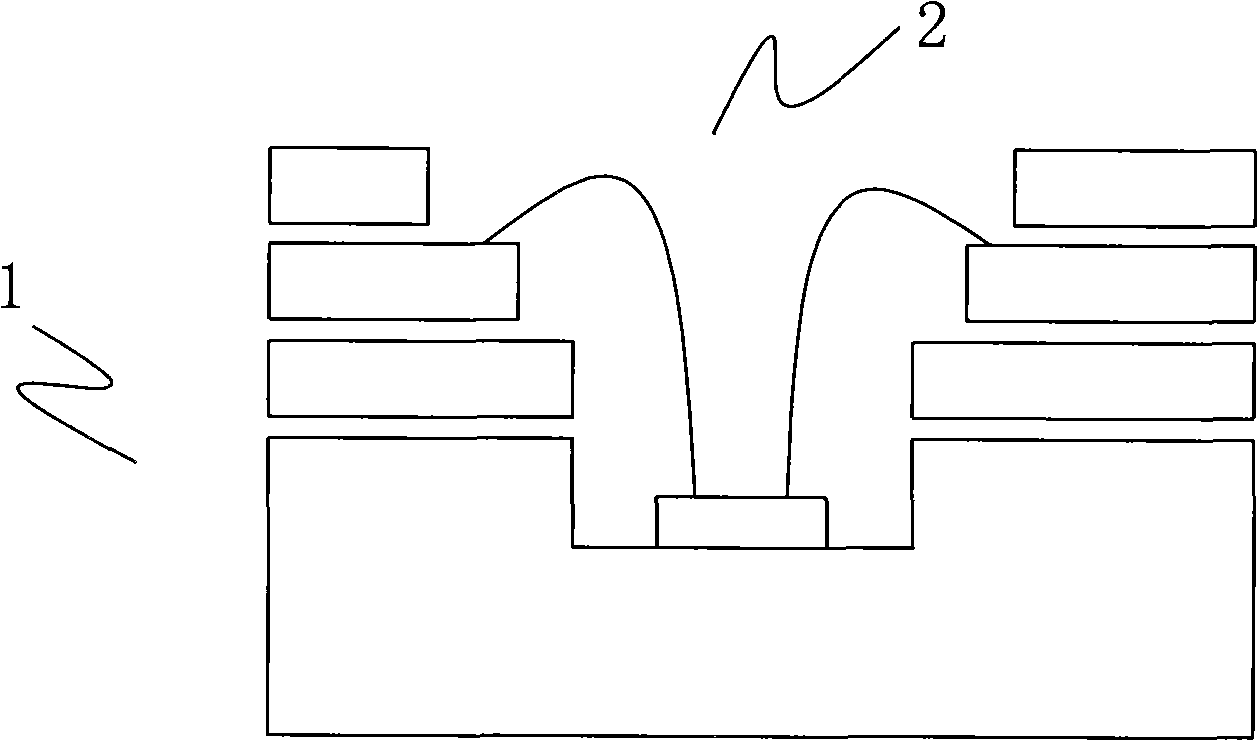

[0035] Embodiment 2: As shown in accompanying drawing 4, the structural principle of this embodiment is consistent with that of Embodiment 1, the difference is that the glass fiber circuit board in the circuit board is improved, and the glass fiber circuit board 1 is from top to bottom The lower layer includes a white oil layer 12, a conductive circuit layer 11 and an insulating layer 13 in sequence, which is consistent with the improvement in the embodiment. A heat dissipation bottom plate 3 is also closely attached to the bottom of the insulating layer 13 through a heat-conducting adhesive 16. The light-emitting diode 2 is preset in the The through holes on the glass fiber circuit board 1 are closely attached to the base plate 3 , and the power lines of the LEDs 2 are also connected to the wiring layer 11 .

[0036] Similarly, the following steps can be used for specific production:

[0037] a. Process the bottom plate according to the size of the circuit board and the distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com