Wearable heating floor

A floor and heat generation technology, which is applied in the structural field of the floor, can solve the problems that affect the efficiency of decoration and installation, the floor cannot be assembled, and the floor boards are scrapped, etc., and achieve the effects of reducing consumption, good environmental protection, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

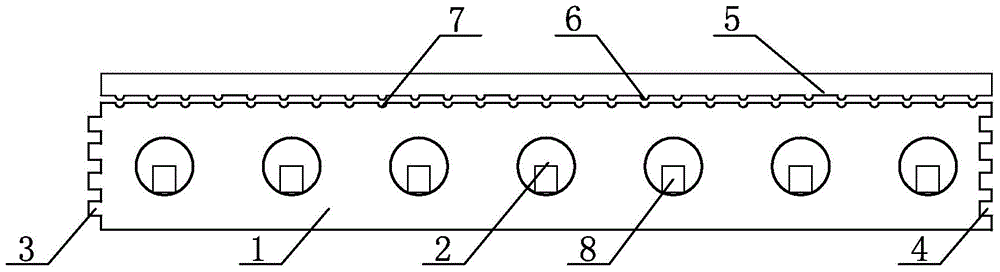

[0009] Such as figure 1 As shown, the present invention includes a floor body 1 and a wear-resistant layer 5. There are several circular cavities 2 along the width direction in the floor body 1, which is conducive to reducing the amount of wood and will not affect the strength of the floor body. The two ends of the main body 1 are provided with several rectangular bosses 3 and rectangular grooves 4, which facilitate the connection and cooperation between the two floor bodies 1, and are easy to install. The manufacturing process of the rectangular bosses 3 and the grooves 4 is simple and low in cost. The surface of 1 has an arc-shaped groove 7 along the width direction; the bottom surface of the wear-resistant layer 5 has an arc-shaped convex circle 6 along the width direction, and the convex circle 6 is embedded in the arc-shaped groove 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com