Environmentally-friendly heating type material-saving floor

An environment-friendly floor technology, applied in the field of floor structure, can solve the problems affecting the efficiency of decoration and installation, the floor cannot be assembled, the floor boards are scrapped, etc., and achieve the effects of reducing gas, good environmental protection and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

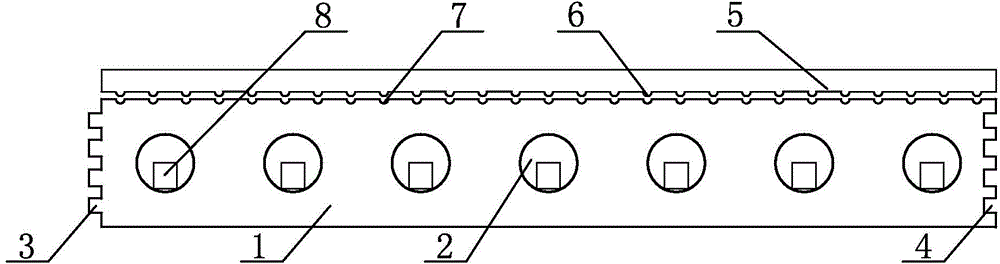

[0009] Such as figure 1 As shown, the present invention includes a floor body 1 and a wear-resistant layer 5. There are several circular cavities 2 along the width direction in the floor body 1, which is conducive to reducing the amount of wood and will not affect the strength of the floor body. An electric heating tube 5 is installed in the circular cavity 2, which can generate heat after being energized, which can not only protect the floor body 1 from moisture, but also increase the indoor temperature, especially in winter, which can reduce the use of gas and coal, and is environmentally friendly Good performance, the two ends of the body 1 are equipped with several rectangular bosses 3 and rectangular grooves 4 respectively, which is convenient for the connection and cooperation between the two floor bodies 1, and the installation is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com