Current-assisted friction additive manufacturing device and method

A technology of additive manufacturing and manufacturing methods, applied in the field of current-assisted friction additive manufacturing devices, can solve problems such as weak interface bonding performance, achieve the effects of increasing interface bonding strength, improving bonding strength and service performance, and increasing interface temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

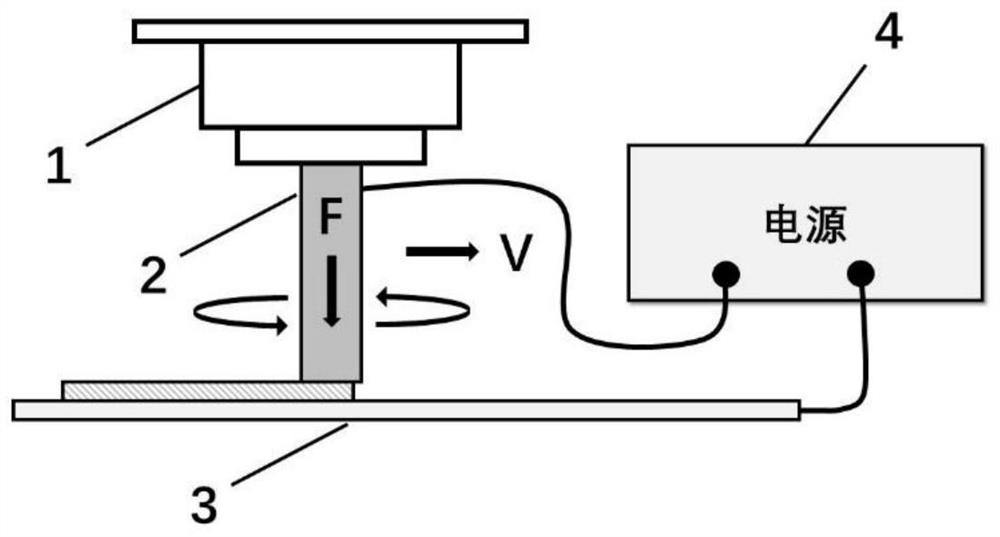

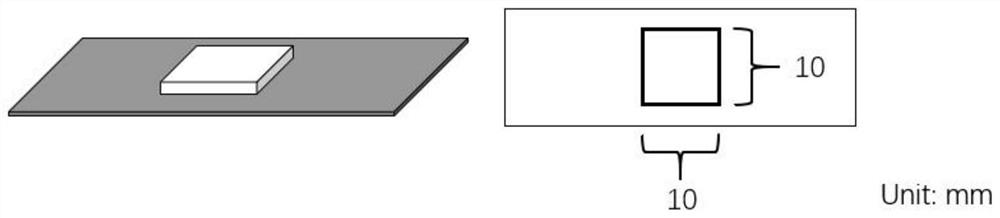

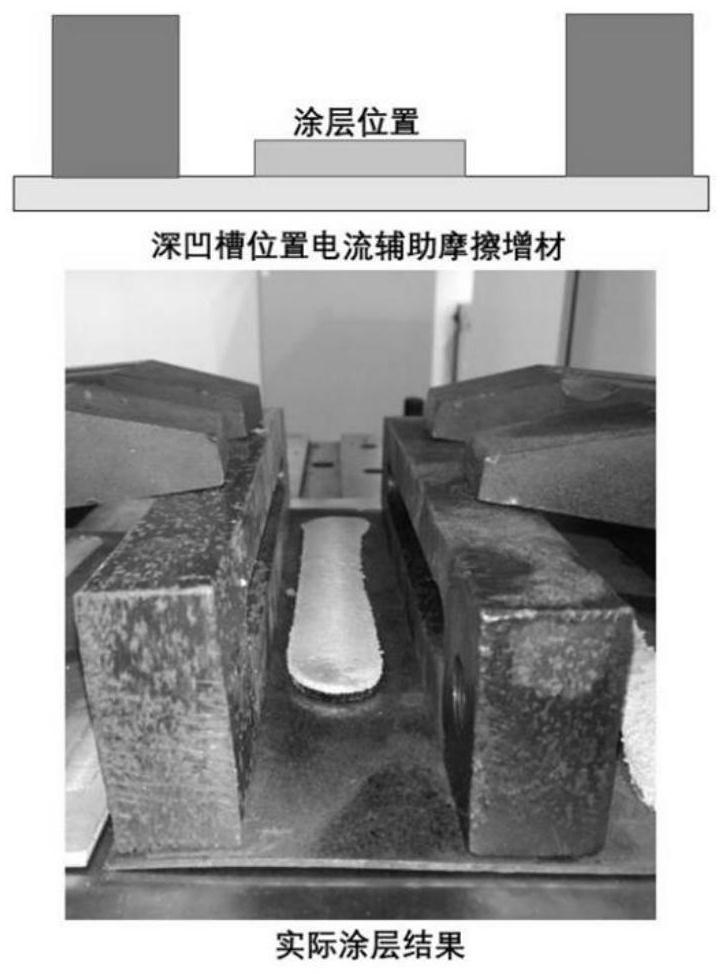

[0037] Such as figure 1 As shown, the aluminum alloy consumable rod 2 is fixed on the friction coating equipment 1 , the positive electrode of the current generating device is connected to the aluminum alloy consumable rod, and the negative electrode of the current device is connected to the substrate material which is a steel plate 3 .

[0038] When preparing a single layer, start the friction coating device first, and then start the current generating device 4 (power supply) to generate current. specific reference figure 1 , first install the aluminum consumable rod used for friction coating on the friction coating device, then fix the steel plate as the substrate material, then the coating material touches the surface of the steel plate while rotating continuously, and at the same time turn on the power of the current generating device, and apply the current synchronously field. Among them, the angle between the aluminum consumable rod and the vertical line on the surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com