USB Type-C connector and fabrication process thereof

A manufacturing process and connector technology, which is applied in the direction of connection, contact manufacturing, and components of connecting devices, etc., can solve the problems of high mold design and development cost, complex assembly process, increased material waste, etc., and reduce labor assembly costs. , Improve the quality of the process and reduce the waste of the material strip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

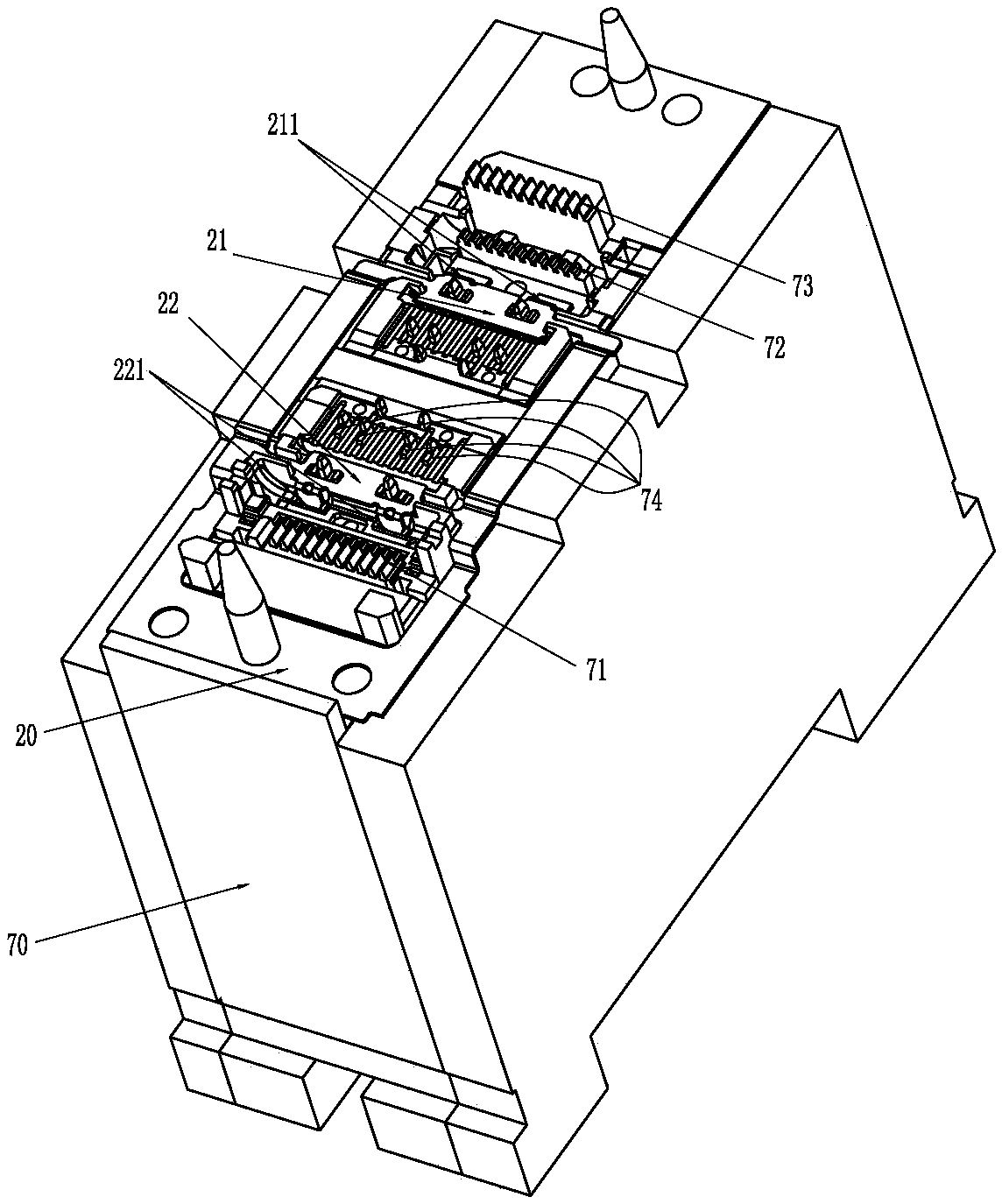

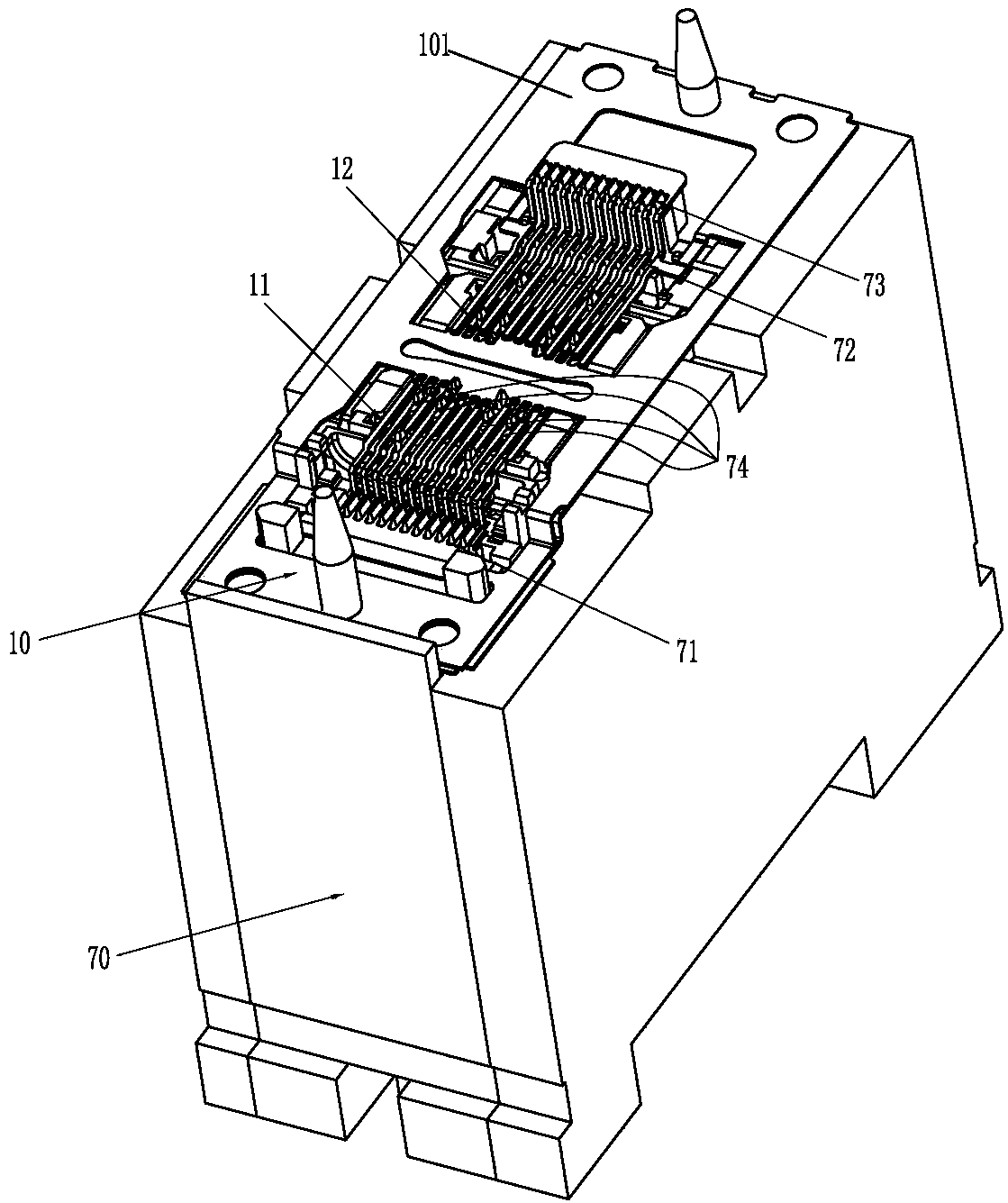

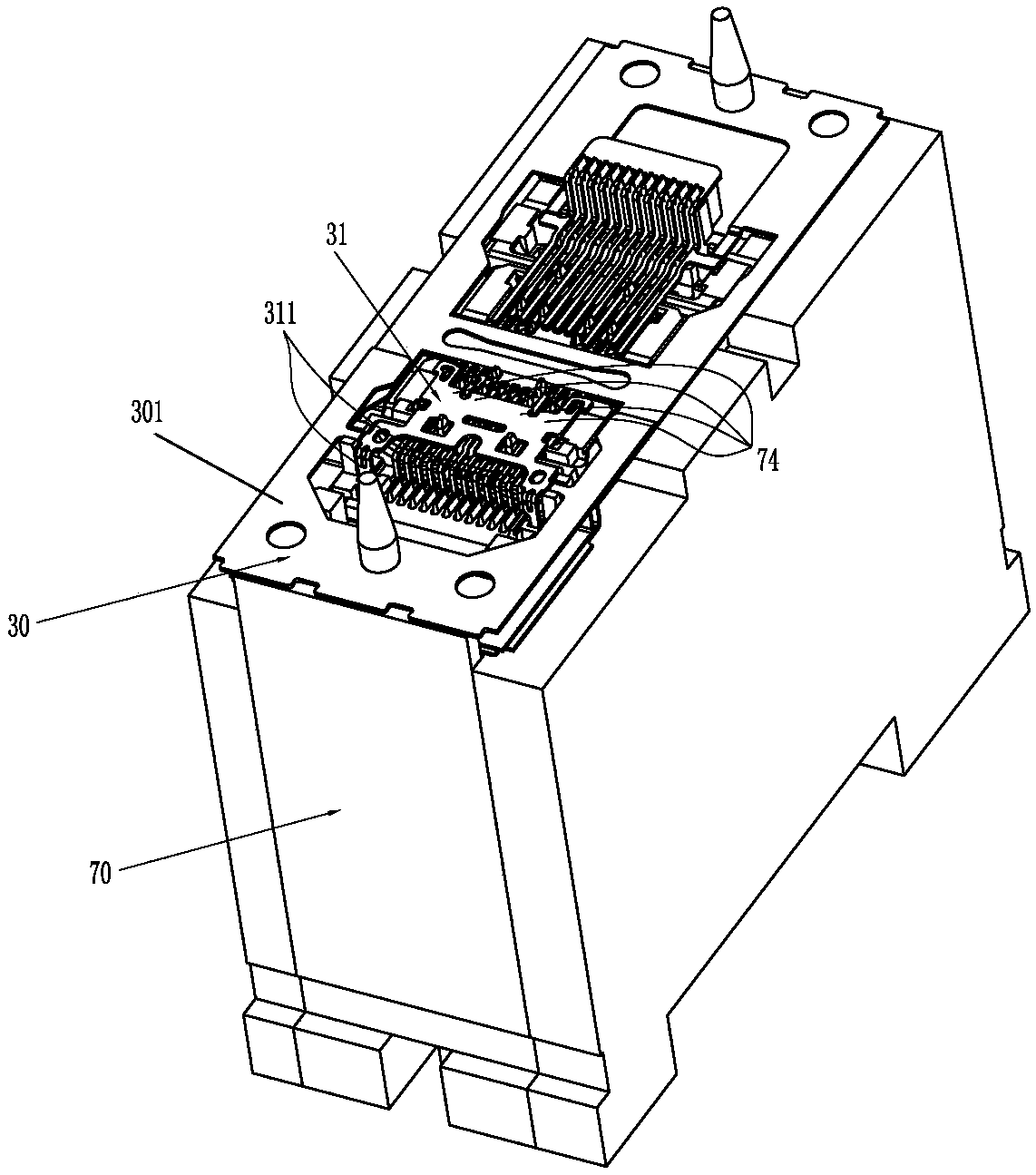

[0066] Please refer to Figure 1 to Figure 16 As shown, it shows the specific structure of the preferred embodiment of the present invention. In this embodiment, a solder plate type USB Type-C receptacle connector is taken as an example for illustration. Since each metal strip is a long-sized extended strip, in order to better reflect the structure, the drawings in this specification only show the partial structure of the strip design.

[0067] A manufacturing process of a USB Type-C connector, comprising the steps of:

[0068] Step 1. Please refer to Image 6 As shown, prepare the first metal strip 10, the second metal strip 20 and the third metal strip 30;

[0069] Wherein, the first group of terminals 11 and the second group of terminals 12 are arranged on the first metal strip 10, here, preferably, the first group of terminals 11 and the second group of terminals 12 are respectively arranged on the first metal strip 10 In the left and right areas, the left and right si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com