A cam type multi-stable reversing valve and its working position switching method

A multi-stable, cam-type technology, applied in the field of solenoid valves, can solve the problems of increasing the cost of using electromagnetic reversing valves and the power consumption of electromagnets, and achieve the effects of reducing control difficulty and cost, eliminating resistance, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

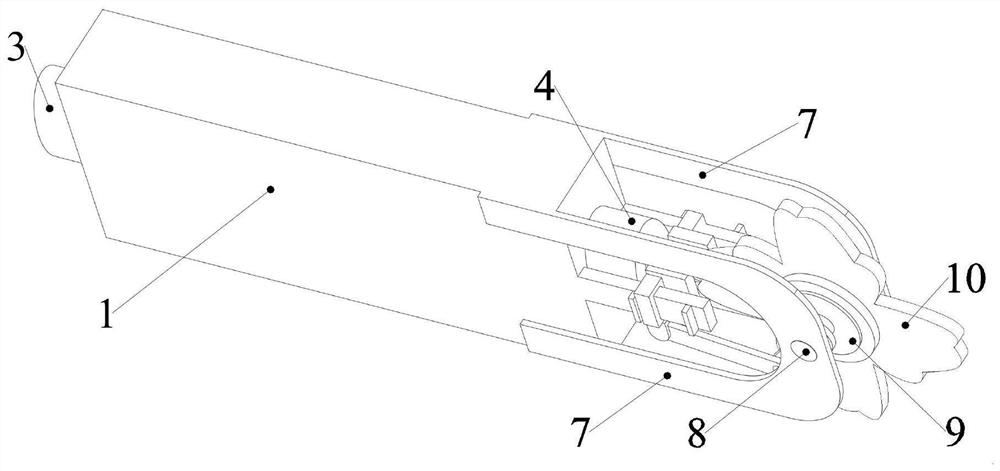

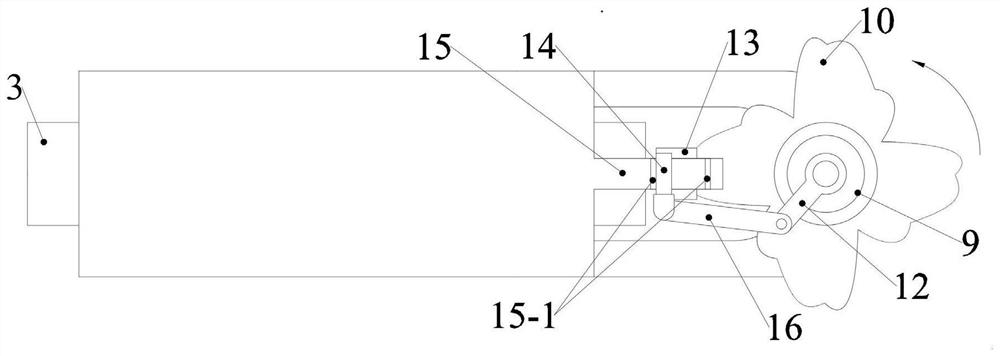

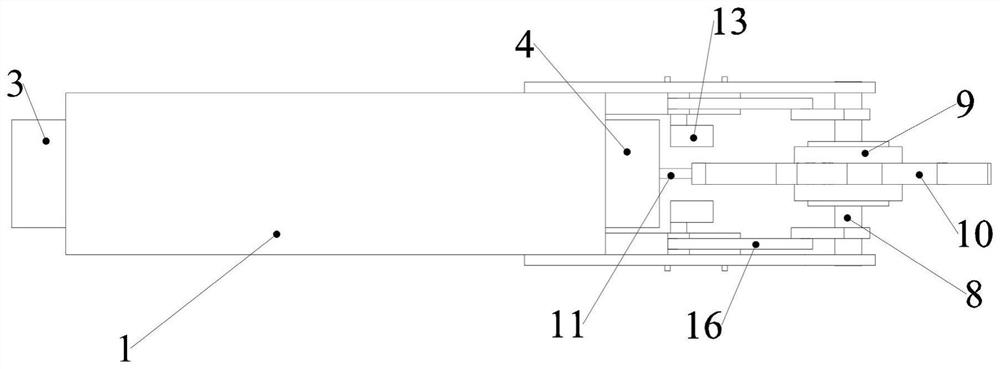

[0031] Such as figure 1 , 2 , 3 and 4, a cam-type multi-stable reversing valve includes a valve seat 1, a valve core 2, a first electromagnet 3, a second electromagnet 4, a moving permanent magnet 5, a suction block 6 and a working bit switching mechanism. Both the first electromagnet 3 and the second electromagnet 4 are de-energized electromagnets; the de-energized electromagnets have magnetism when no power is applied, and the magnetism disappears after being energized. The suction block 6 is made of a magnetic material (a material that can be magnetized). The valve seat 1 is provided with a valve core placement channel. The first electromagnet 3 and the second electromagnet 4 are respectively fixed at both ends of the spool placement channel. The spool 2 is elongated and forms a sliding pair with the spool placement channel. The valve core 2 is located between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com