Method for manipulating microscopic particles and analyzing the composition thereof

A particle and sample technology, used in the field of semiconductor sample surface removal and analysis of tiny particles, which can solve problems such as reducing the cycle time of pollutant removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

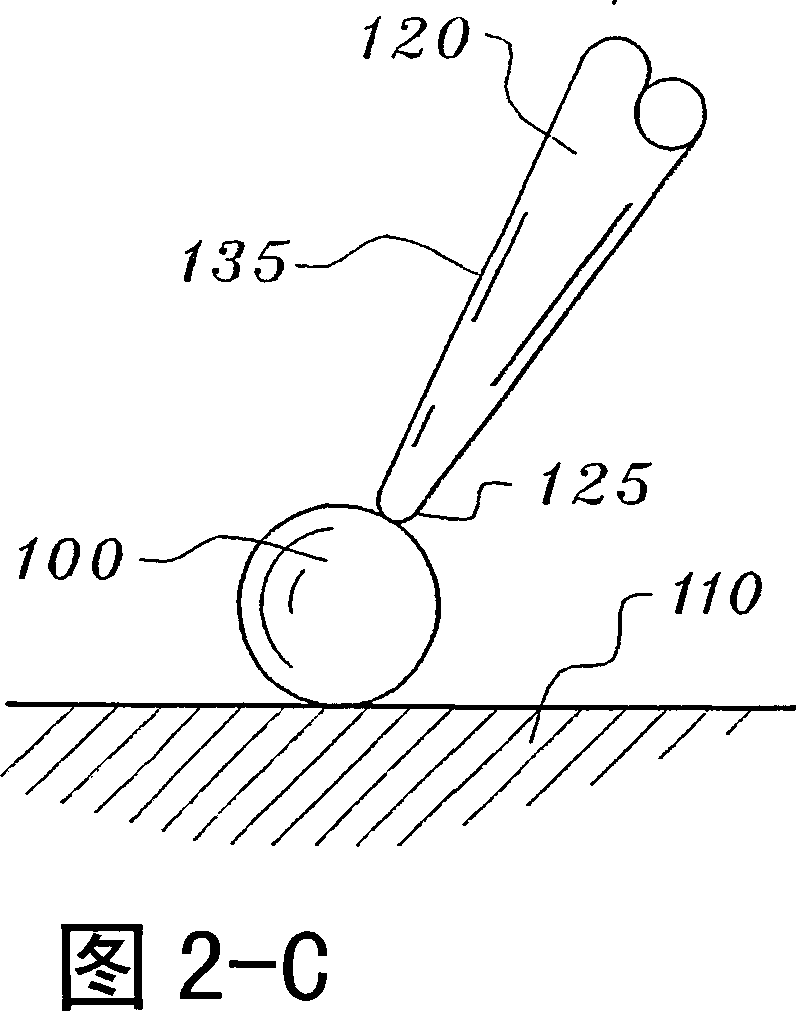

[0024]Semiconductor manufacturing typically uses scanning electron microscopes (SEM), focused ion beam (FIB) instruments, or scanning Auger microprobes (SAM) to analyze tiny particles. FIB instruments are available in single-beam or dual-beam (SEM and ion beam) modes. Commonly used FIB instruments are manufactured by FEI Corporation of Hillsboro, Oregon, and there are several models of 200, 235, 820, 830 and 835. The probe 120 mentioned below is a component of the micromanipulator connected to the FIB instrument with vacuum feedthrough. A conventional such micromanipulator is the Model 100 micromanipulator manufactured by Omniprobe Corporation of Dallas, Texas. Typical SAM instruments include Peabody, JAMP-7810 and JAMP-7830F manufactured by JEOL USA, Inc. of Massachusetts.

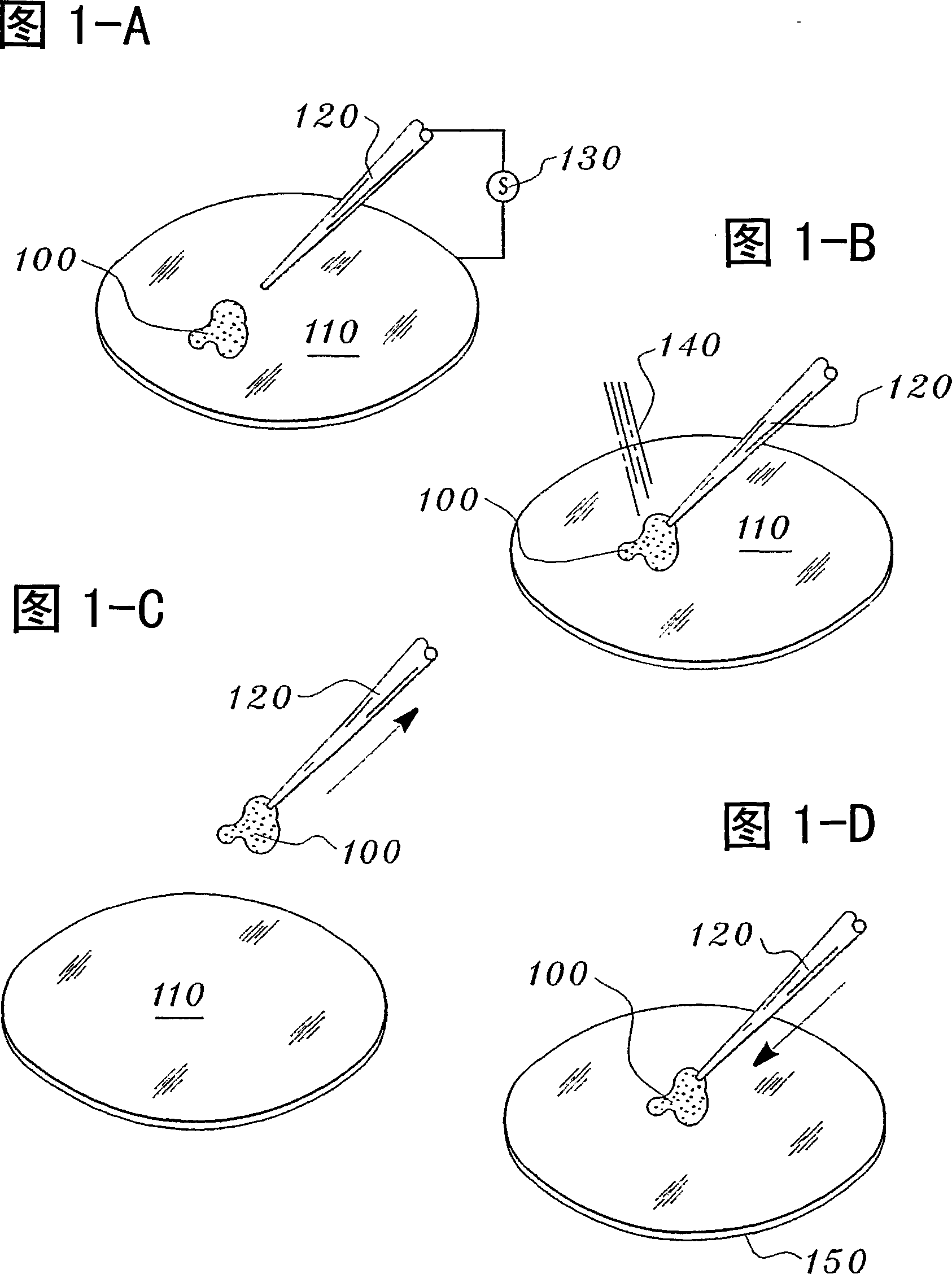

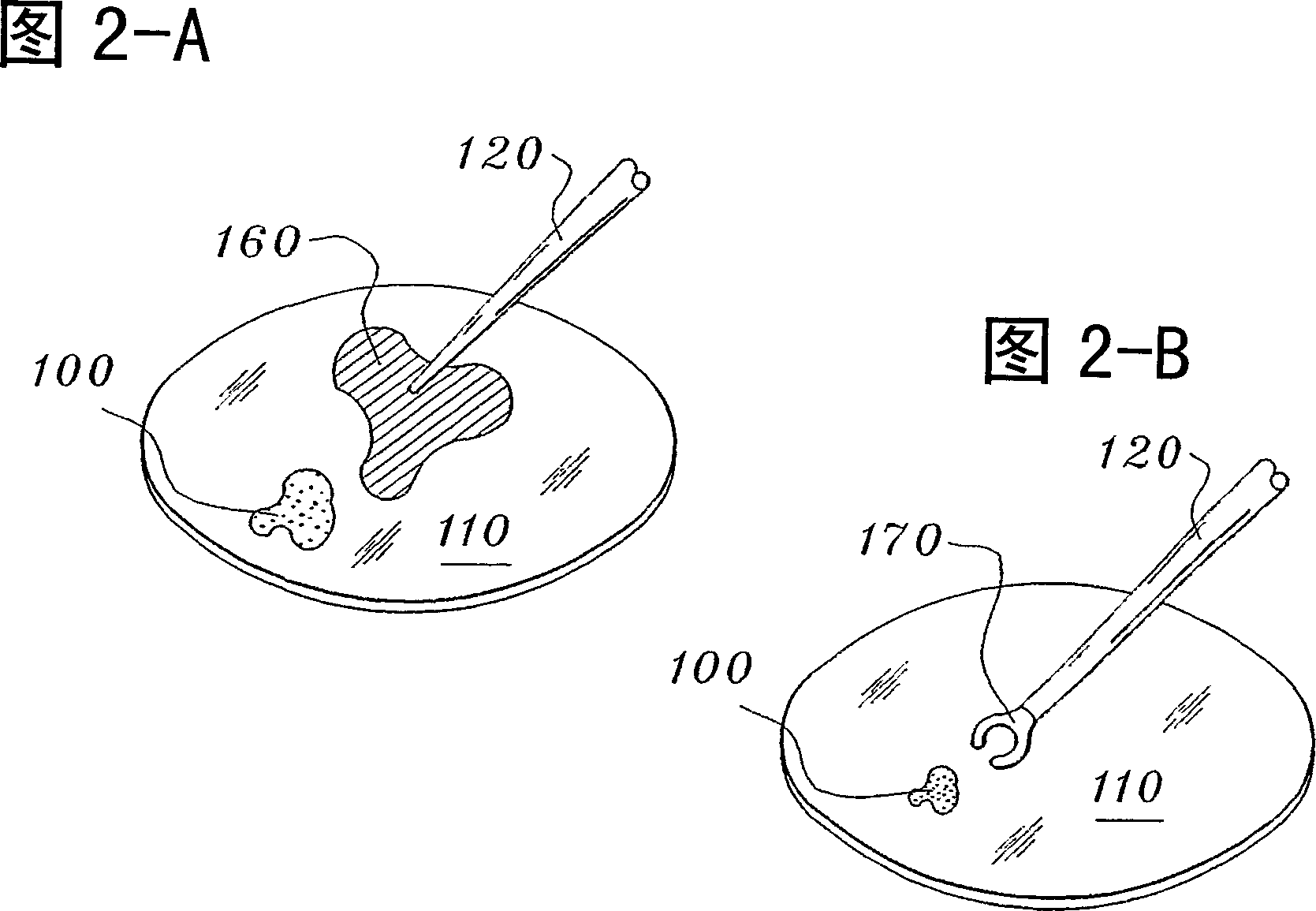

[0025] Figure 1 depicts a common setup for handling and analyzing particles. FIG. 1A shows a particle 100 to be detected resting on a first sample surface 110 . The micromanipulator probe 120 is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com