Short-distance coincident section heading machine

A short-distance, roadheader technology, applied to mining equipment, earthwork drilling, tunnels, etc., to achieve the effects of refined equipment, dispersed disturbance, and local stress reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

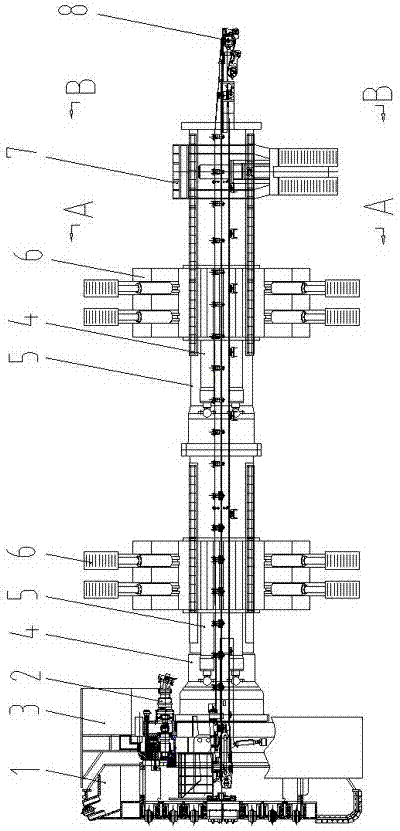

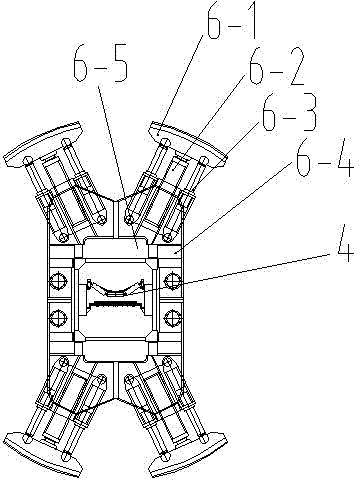

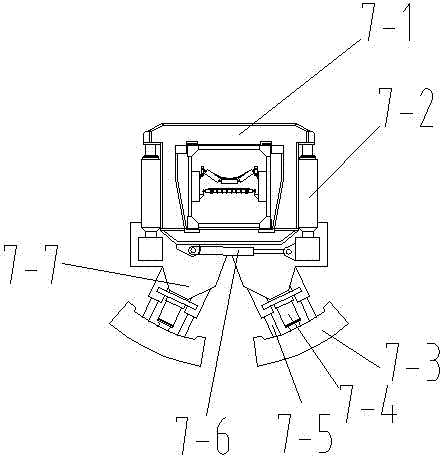

[0022] Such as figure 1 As shown, a short-distance overlapping cross-section tunneling machine is sequentially connected by a cutter head 1, a drive 2, a shield 3, a propulsion and support system, a tail support system 7, and a slag conveyor 8, and is controlled by a control system. The propulsion and support system is composed of two main beam propulsion shoe systems set in series, with two modes of excavation mode with step change and excavation mode without step change to deal with different surrounding rocks, and the arrangement of the spreader shoes in the main beam pusher shoe system The azimuth enables the roadheader to carry out multiple overlapping excavations, and each shoe has multiple pairs of shoe feet to disperse the local stress of the shoe on the rock and reduce the disturbance to the rock.

[0023] The cutter head 1 is a plane cutter head or a conical cutter head, and the cutter head 1 is connected with the ring of the drive 2 through a flange. The cutter head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com