Prefabricated fabricated pier suitable for moderate-strong earthquake area and construction method of prefabricated fabricated pier

A prefabricated assembly, seismic zone technology, applied in the erection/assembly of bridges, bridges, bridge construction, etc., can solve the problems of weak hysteretic energy dissipation capacity, easy damage of prefabricated piers, and large local stress, so as to reduce local stress, reducing earthquake damage, reducing the effect of stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

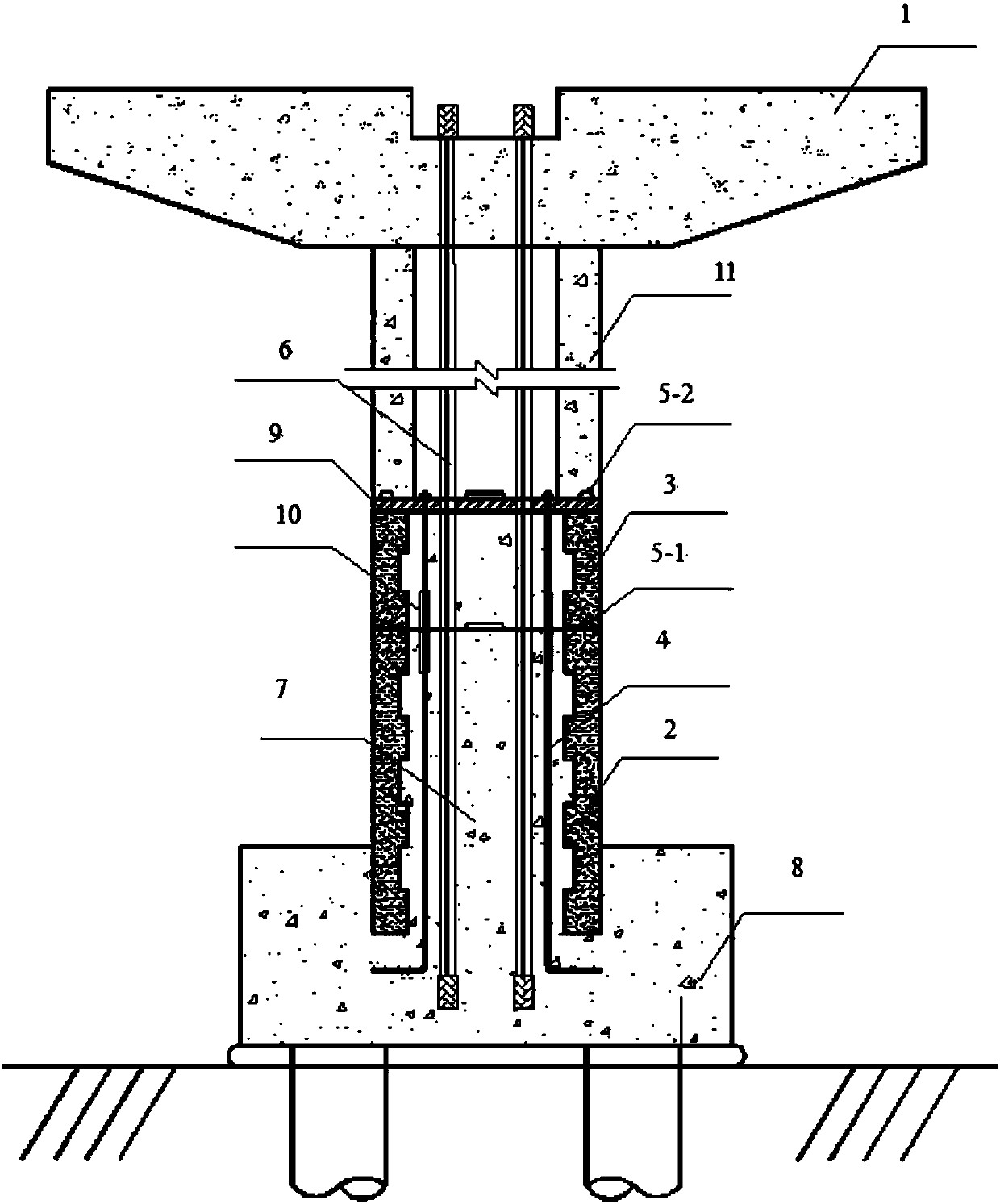

[0058] The section of the pier body is a hollow rectangular section with chamfers.

[0059] A construction method for prefabricated bridge piers suitable for moderately strong earthquake areas, the method steps are as follows:

[0060] Step 1: Make cover beam 1, prefabricated segment 11, bottom UHPC sleeve 2 and transition UHPC sleeve 3 in the precast yard; cover beam 1 and precast segment 11 are poured with ordinary concrete, bottom UHPC sleeve 2 and transition UHPC Sleeve 3 is poured with ultra-high performance steel fiber reinforced concrete, and the volume content of steel fiber is 2%~4%.

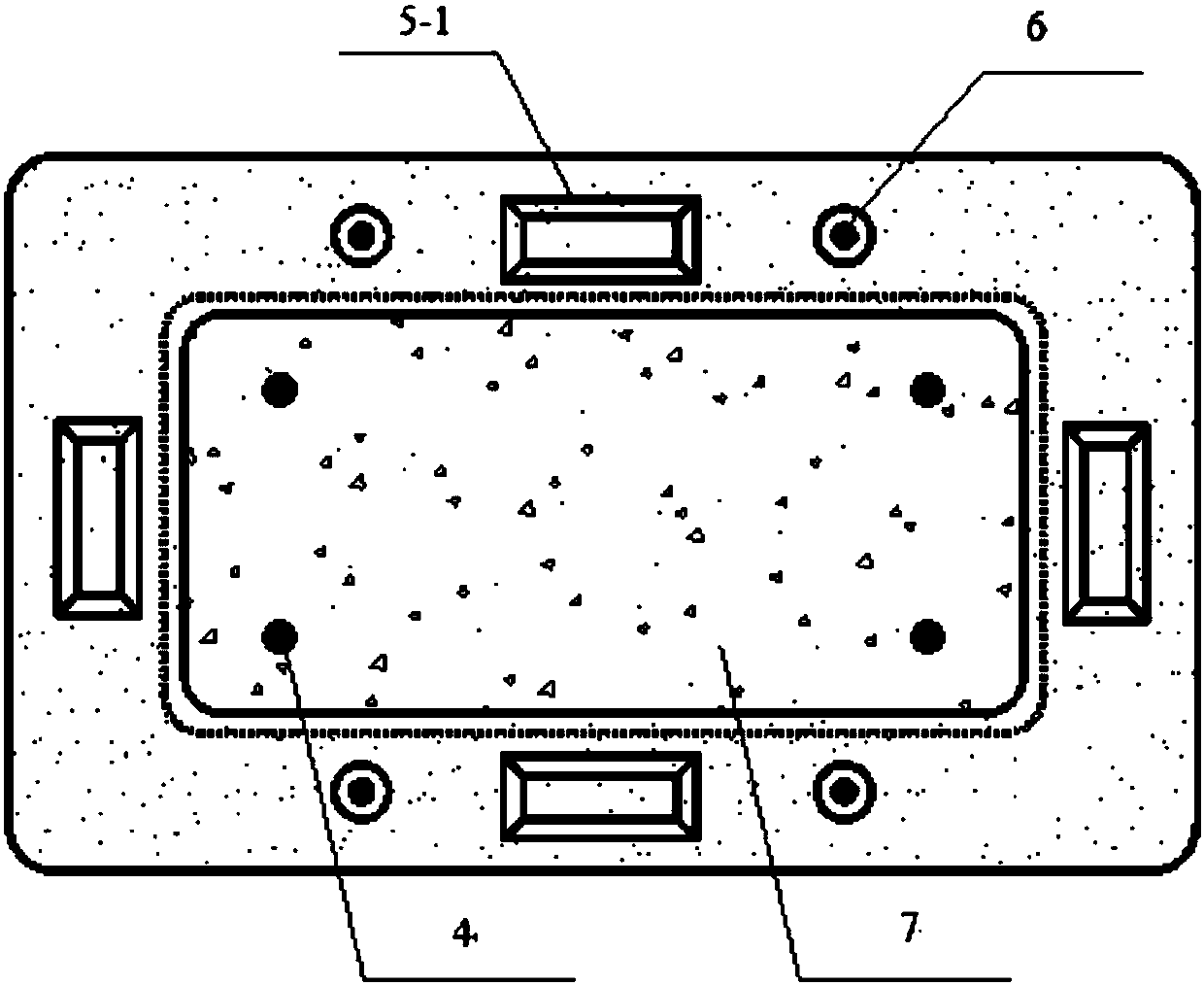

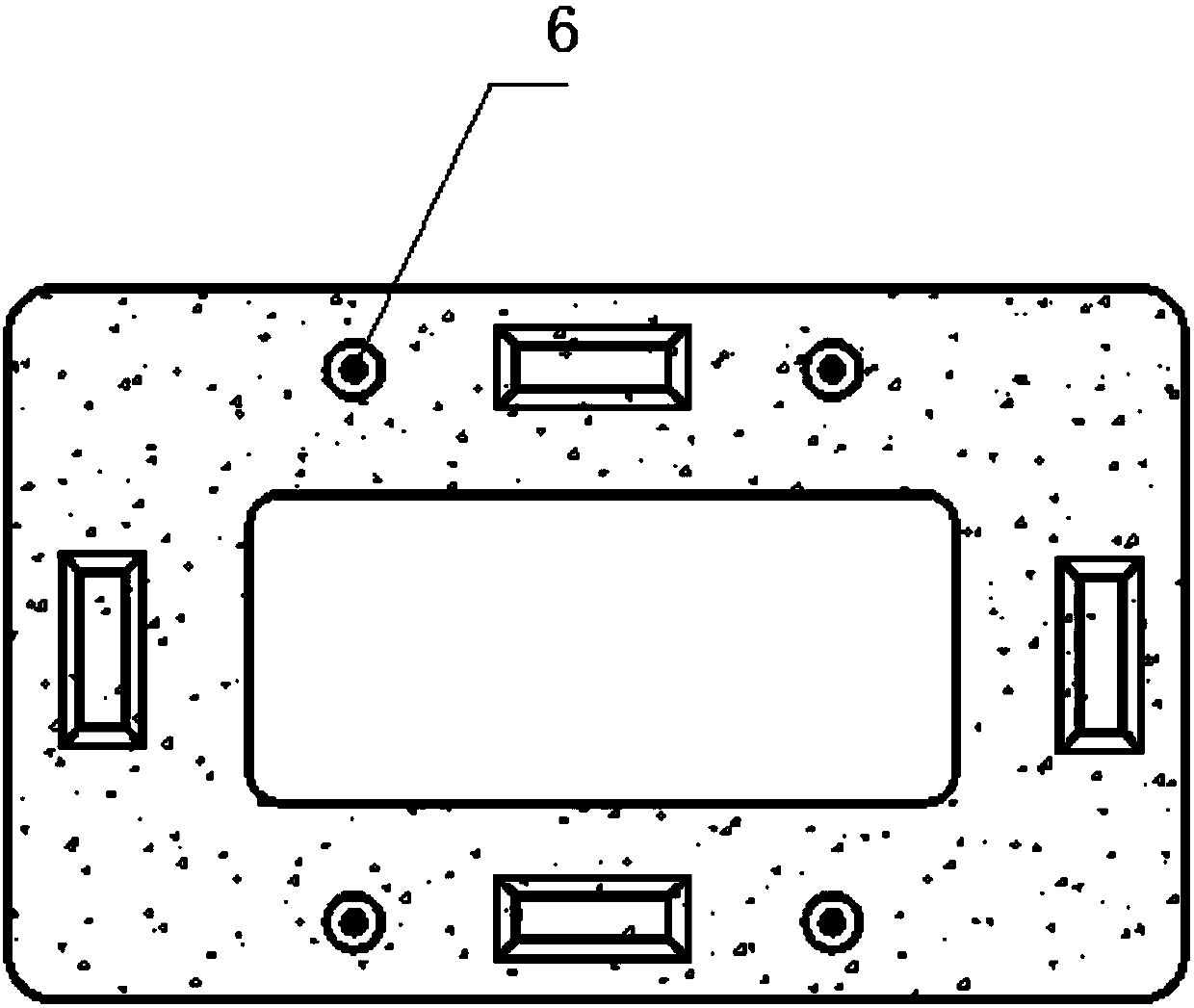

[0061] Four sleeve shear keys 5-1 are evenly distributed on the top surface of the bottom UHPC sleeve 2, and four sleeve shear key slots are distributed on the corresponding positions on the bottom surface of the transition UHPC sleeve 3, through which the sleeve shear keys 5-1 and the sleeve Barrel shear force keyway fit limit. Four steel plate shear keys 5-2 are evenly distributed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com