Steel cage lifting device for tubular pile industry

A hoisting device and industry technology, used in sheet pile walls, transportation and packaging, load hanging components, etc., can solve the stress point of the steel cage and the bending deformation of the steel cage, the deformation of the steel cage and the collapse of the steel cage, and the threat to the personal safety of construction workers, etc. problem, to achieve the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

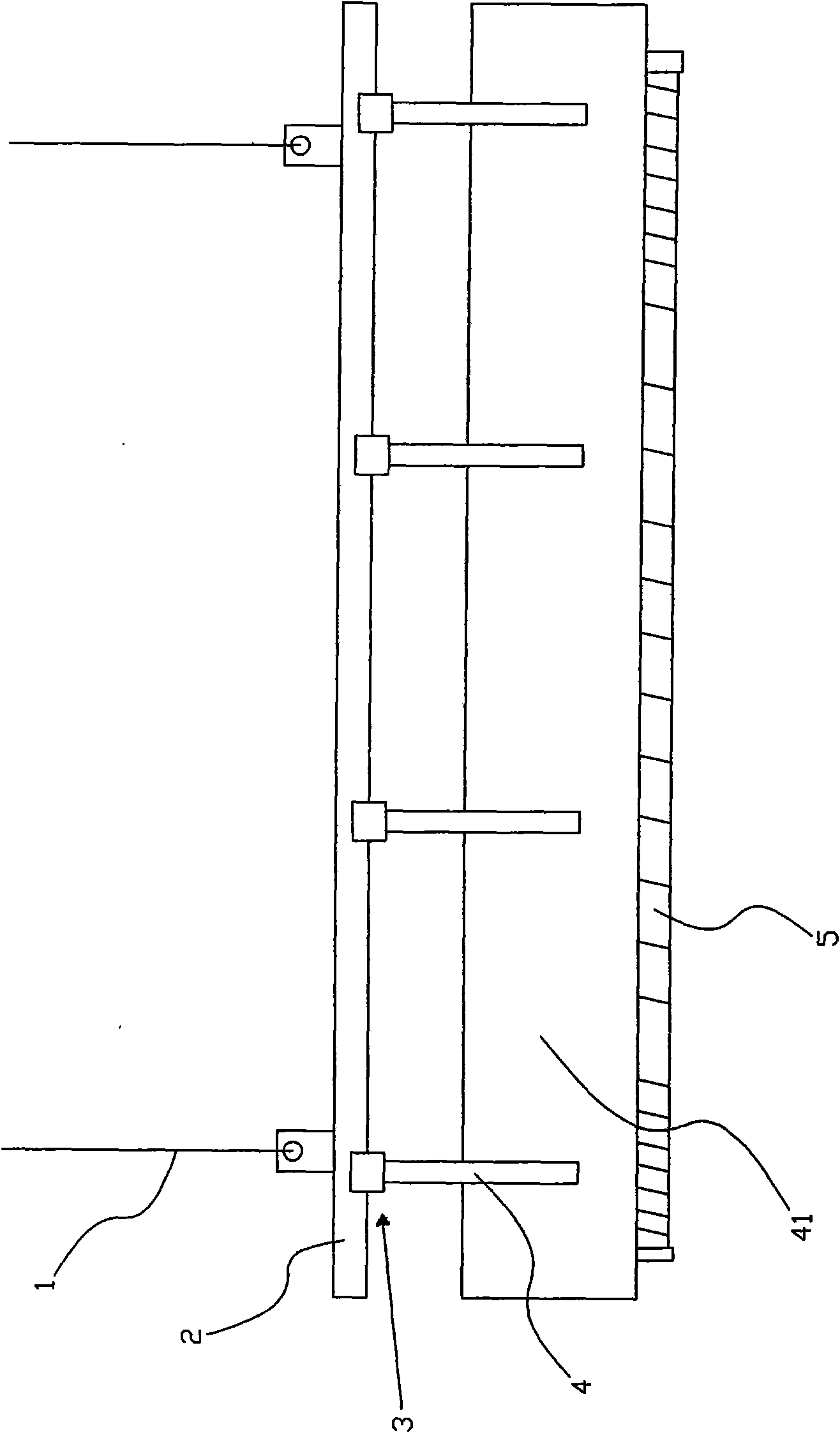

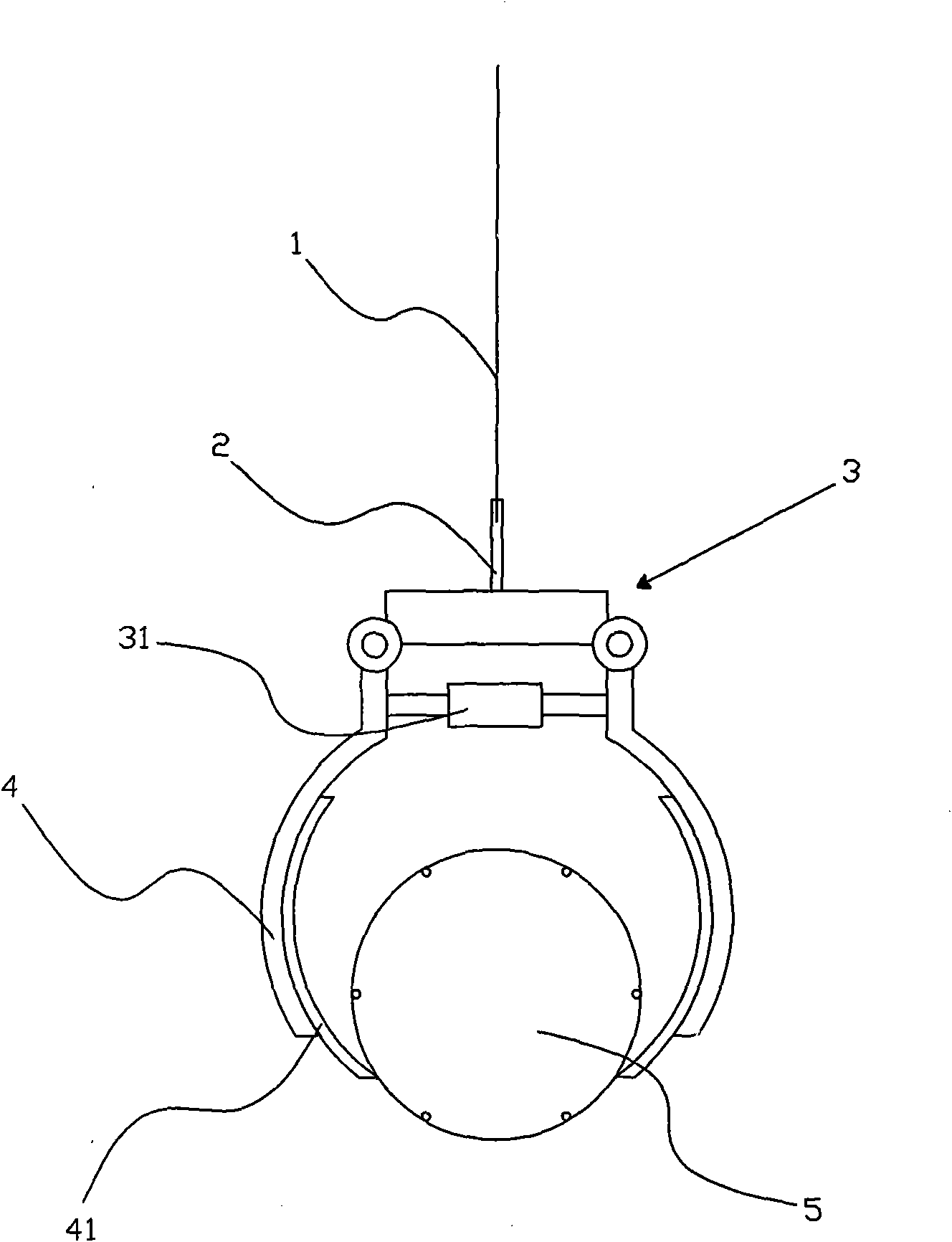

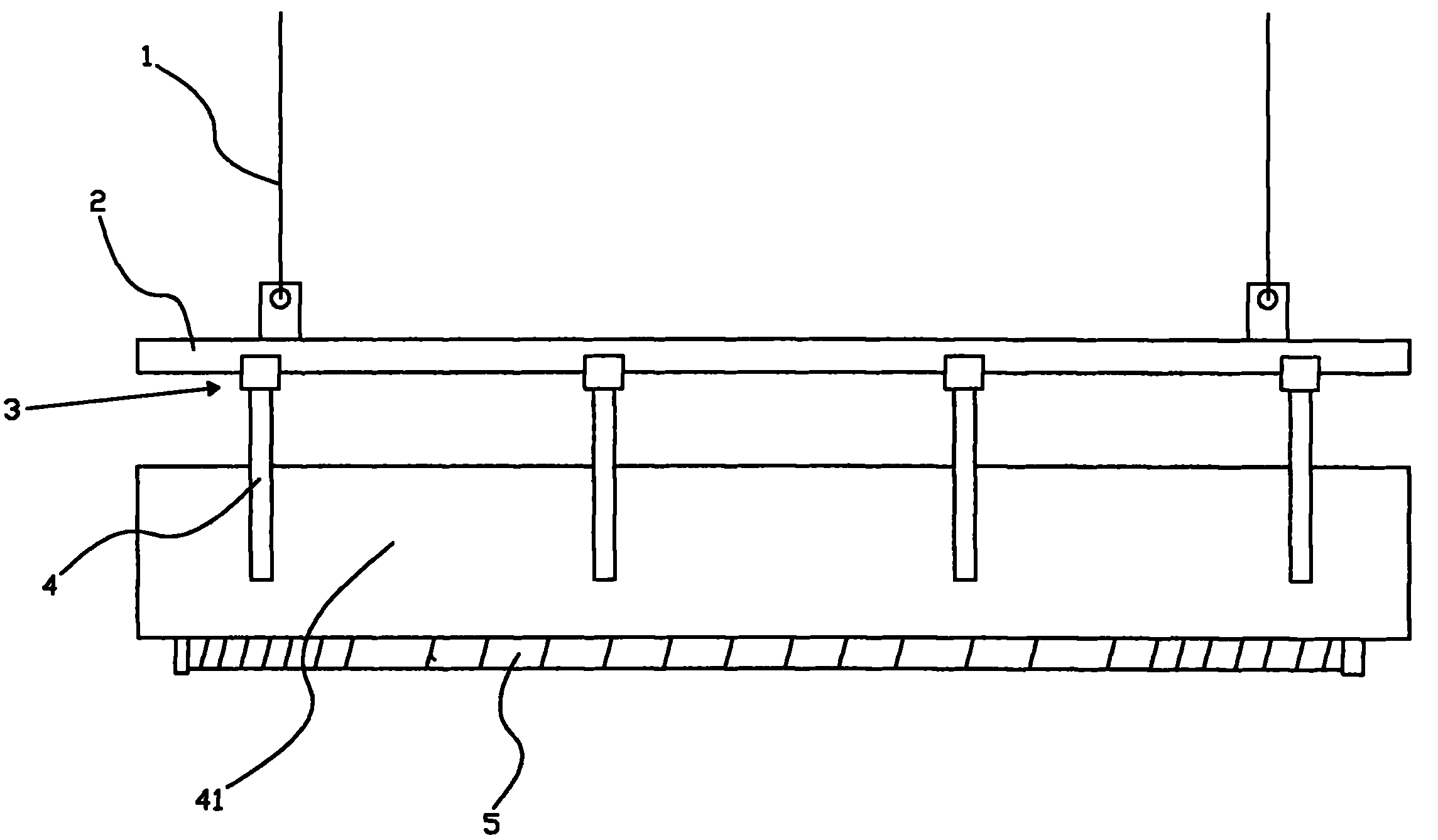

[0014] refer to figure 1 , figure 2 , a steel cage hoisting device in the pipe pile industry, including a steel wire rope 1 connected to a crane, a bracket 2 is hoisted under the steel wire rope 1, two or more steel wire ropes are fixed, and a clamping mechanism 3 is fixedly installed on the bracket 2. The two ends of the tightening mechanism 3 are telescopic rods 31, and the ends of the telescopic rods 31 are connected with manipulators 4.

[0015] The hoisting steps are as follows:

[0016] a. Hoist the bracket 2 on the wire rope 1;

[0017] b. By lowering the steel wire rope 1 to lower the bracket 2, the telescopic rod 31 of the clamping mechanism 3 is extended to control the manipulator 4 to open, so that the manipulator 4 can accommodate the steel cage 5 to enter;

[0018] c. Lowering the bracket 2 makes the lowermost end of the manipulator 4 lower than the upper part of the steel cage 5; so that when the manipulator is folded, most of the steel cage will be wrapped i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com