Girder-declining construction method for steel box girder spanning railway trunk line

A construction method and technology of steel box girders, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as no reflection, no particularly good beam drop construction method, etc., to ensure overall stability and local stability of the beam body resistance, increase the effect of anti-overturning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A steel box girder drop girder construction method across the main railway line, which includes the following three stages:

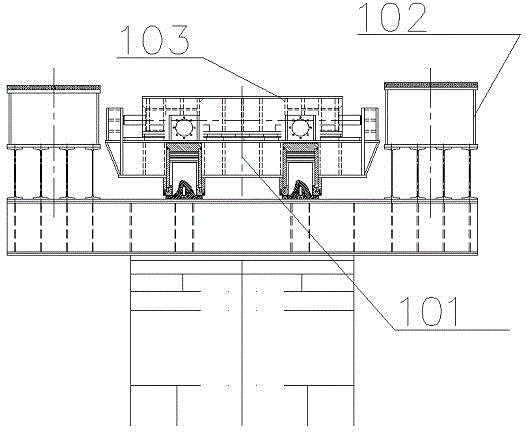

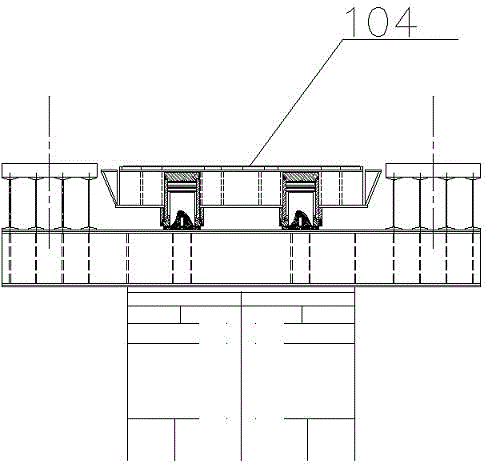

[0028] The first stage: first, the walking-type pushing equipment 101 is used to directly drop the beam 20--40cm, and the steel box girder falls on the box-shaped pad beam 102 of the beam section of the pushing equipment 101, such as figure 1 Shown; Then, remove the horizontal slide block 103 on the top of the pushing equipment and the reaction seat around the horizontal sliding block, drop the beam 40--60cm with the jacking device 104 at the bottom of the pushing equipment, and the steel box girder falls on the I-shaped steel, as figure 2 shown;

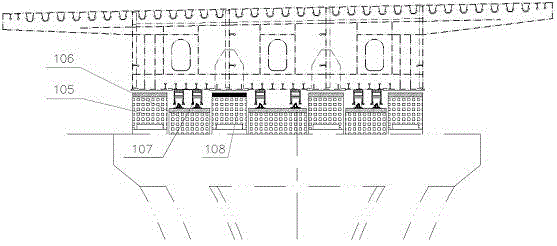

[0029] The second stage: the pushing equipment 101 used in the first stage is dismantled, and three pier 106 are set up between the support pad stones 106, and the pier 106 is 100 cm long, 150 cm wide, and 100 cm high. Place a one-way jack 107 on the pier 106, and the one-way jack 107 lifts the steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com