Full-soluble fracture bridge plug with novel structure

A new type of structure and bridge plug technology, which is applied in drilling equipment, wellbore/well parts, earthwork drilling and mining, etc., can solve problems such as low reliability, easy to stick metal surface, improper material selection, etc., to increase construction safety , Eliminate the phenomenon of tooth collapse and improve the effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

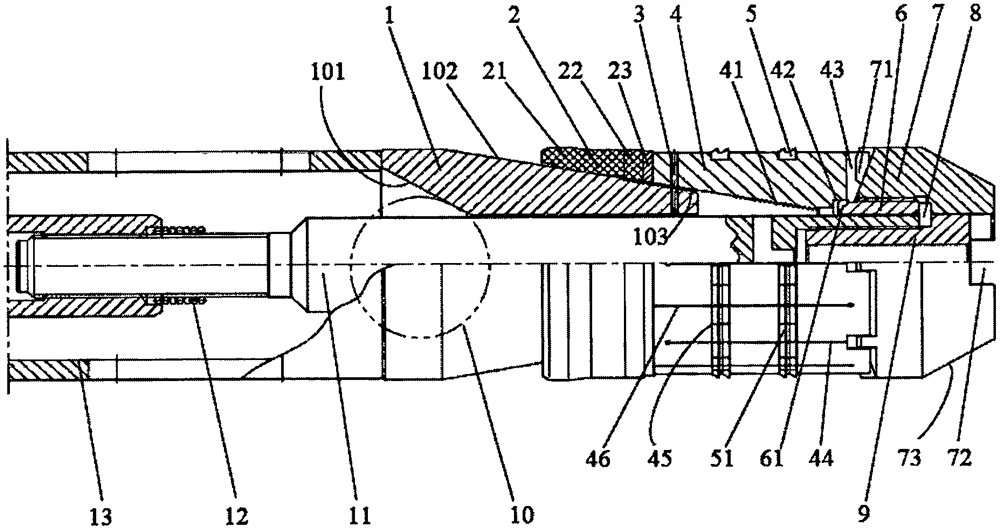

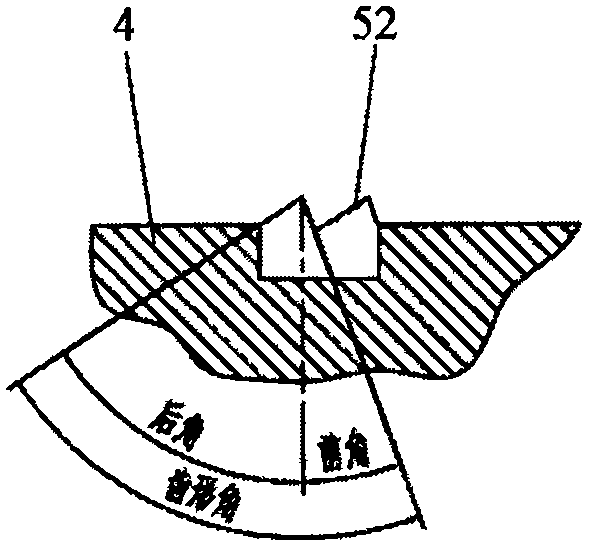

[0009] Such as figure 1 , define the left end in the figure as the upper end of the soluble bridge plug in this scheme. A fully soluble fracturing bridge plug of a new structure according to the present invention includes a male cone 1, a sealing assembly 2, a screw 3, a slip female cone 4, a slip ring 5, a shear ring pressure cap 6, a base 7, a shear Parts such as ring 8, shear ring seat 9, soluble ball 10 are formed. In order to cooperate with the construction of the setting tool, the accessories provided by the present invention include a central pull rod 11, a locking torsion spring 12, and a pusher 13. Some setting tools require an adapter between the central pull rod 11 and the setting tool.

[0010] The male cone 1 is a part with an outer cone surface 102 and an inner cone surface 101 of the ball seat, and the cone angle of the outer cone surface is 16°-24°; the inner cone surface 101 of the ball seat is on the inner surface of the upper end of the male cone 1 , the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com