Flexible spring

A technology of flexible springs and vortex grooves, which is applied in the direction of springs, springs/shock absorbers, and spring components composed of several springs. It can solve the problems of asymmetric motor magnetization structure, direct friction between piston and cylinder, and damage to cylinder and Piston clearance sealing and other issues to achieve the effect of small deformation, uniform stress distribution and large radial stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

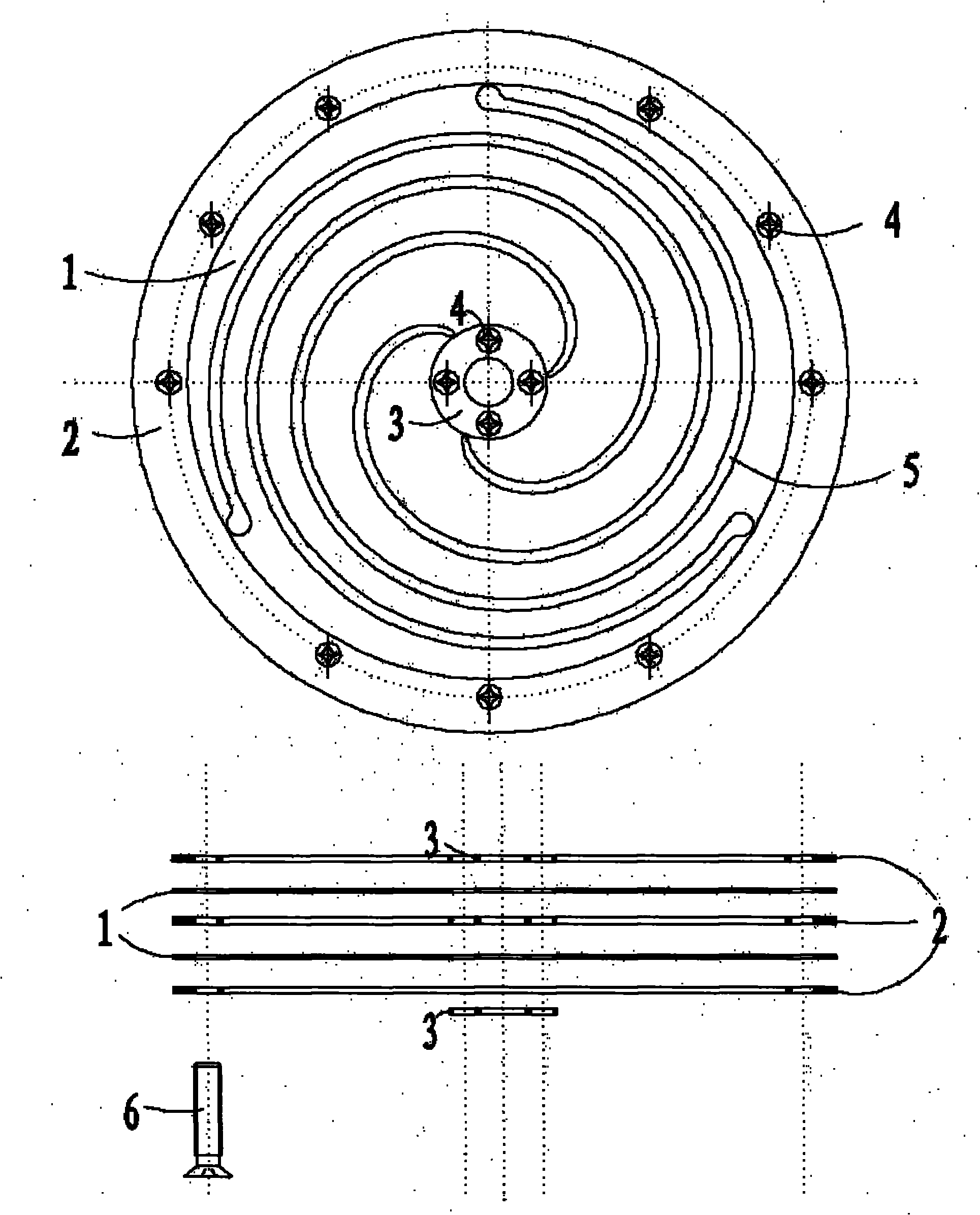

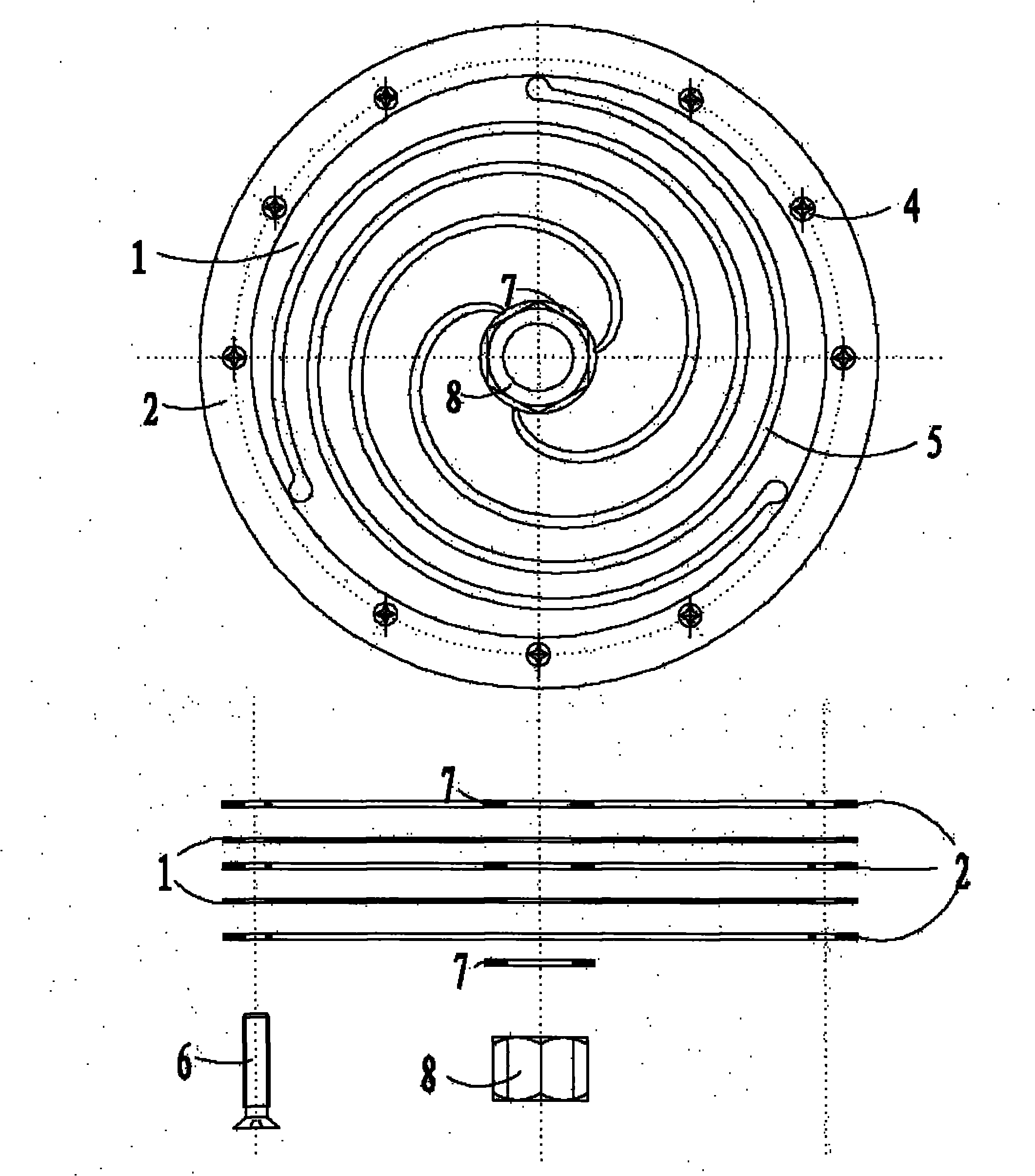

[0017] The specific implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples, but the protection scope of the present invention should not be limited thereby.

[0018] Flexible spring is a part with a certain rigidity processed on the elastic sheet material according to a specific profile, the thickness is generally 0.2mm ~ 3mm, and its production materials are generally stainless steel spring (1Cr18Ni9Ti), beryllium bronze.

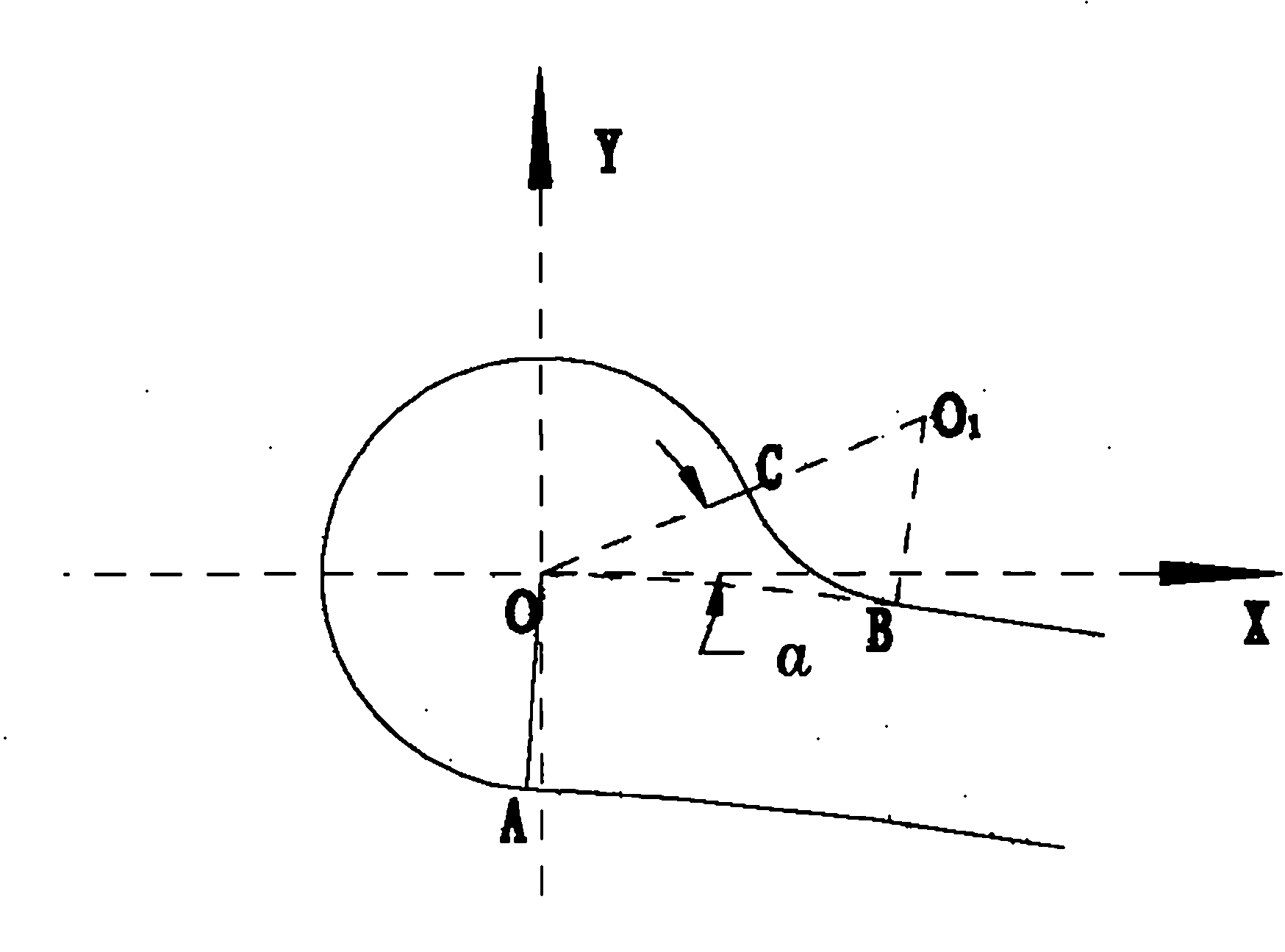

[0019] Profile shape of flexible spring: This invention uses the Fermat curve equation as the basic algorithm to determine the profile line of the spring vortex groove on the flexible spring. There are three profile lines, and the three profile lines are evenly distributed at 120° angles. The following is the profile line mathematical expressions.

[0020] Symbol definitions in the equation:

[0021] A: The radius of the starting point of the vortex groove profile...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com