Flexible pipe having pressure armour layer and components thereof

A technology of hoses and components, applied in the directions of hoses, pipes/pipe joints/fittings, pipes, etc., can solve the problem of difficulty in obtaining contours with large heights, achieve high burst pressure, increase hydrostatic external pressure, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

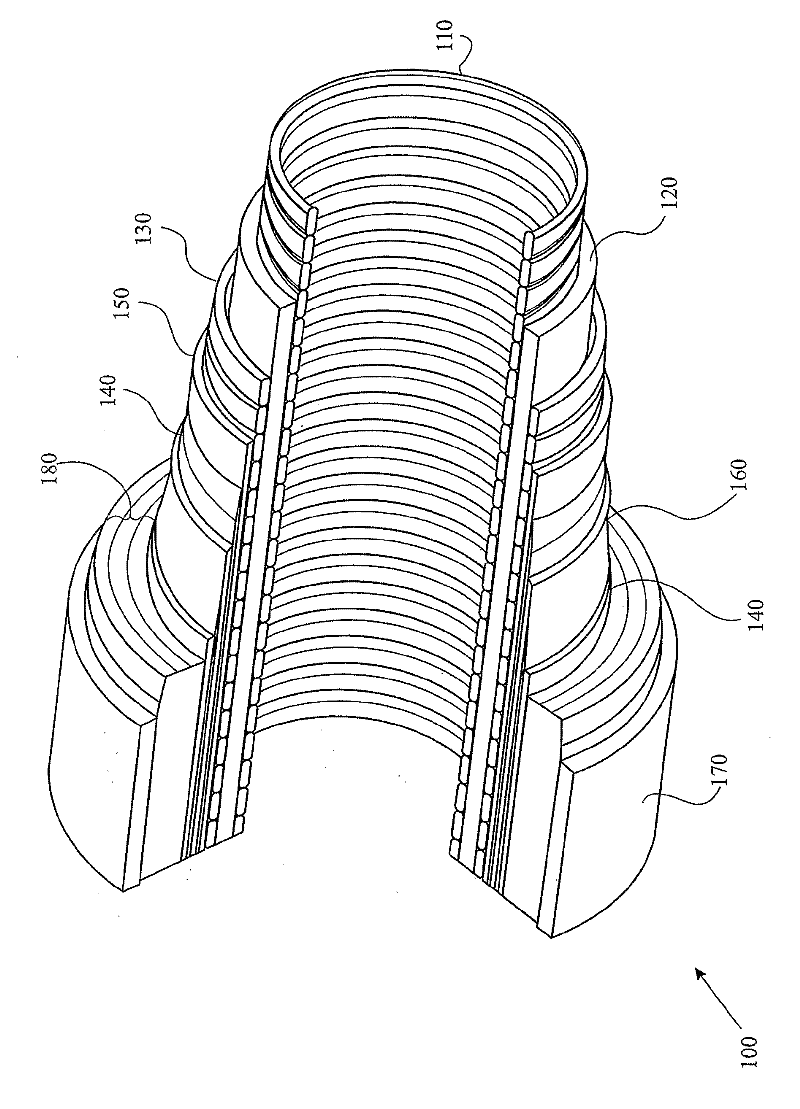

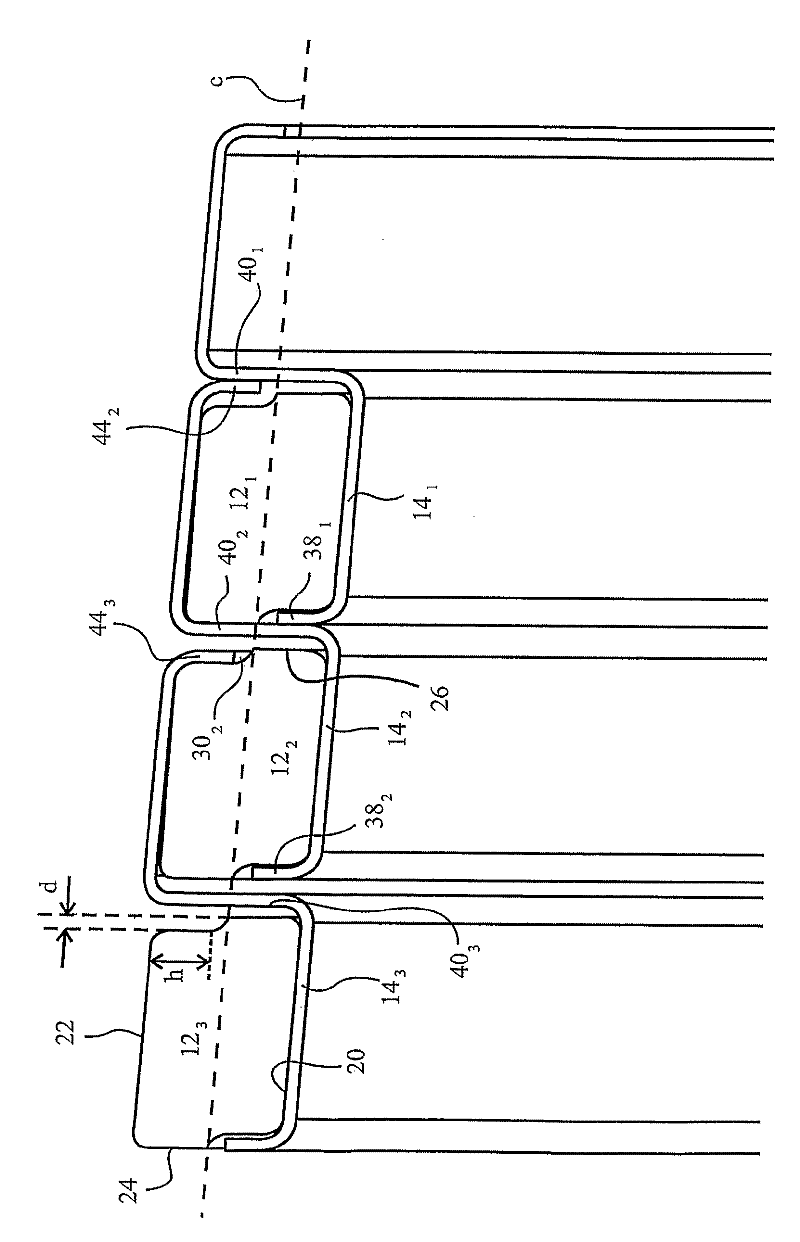

[0034] Reference is made to the hose throughout the instructions. It should be understood that a hose is an assembly of a portion of a tubular body and one or more end fittings, the ends of the tubular body terminating in each end fitting. figure 1 Illustrated how the pipe body 100 is formed from a composite of materials forming a pressure conduit-containing laminate in accordance with an embodiment of the present invention. Although in figure 1 A number of individual layers are shown, but it should be understood that the invention is broadly applicable to composite pipe structures comprising two or more layers. It should also be noted that the various layer thicknesses are shown for illustrative purposes only.

[0035] Such as figure 1 As shown, the tubular body includes an innermost carcass layer 110 and a pressure sheath 120 . Carcass 110 provides an interlocking metallic structure that can be used as the innermost layer to prevent internal pressure sheath 120 from full...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com