Shredding and rubbing device for silage harvester

A technology of silage and kneading device, which is applied to cutting equipment, agricultural machinery and implements, and grain processing, etc. It can solve the problems of silage retention, clogging of chopping drums, and large resistance, so as to reduce local stress and improve quality , the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

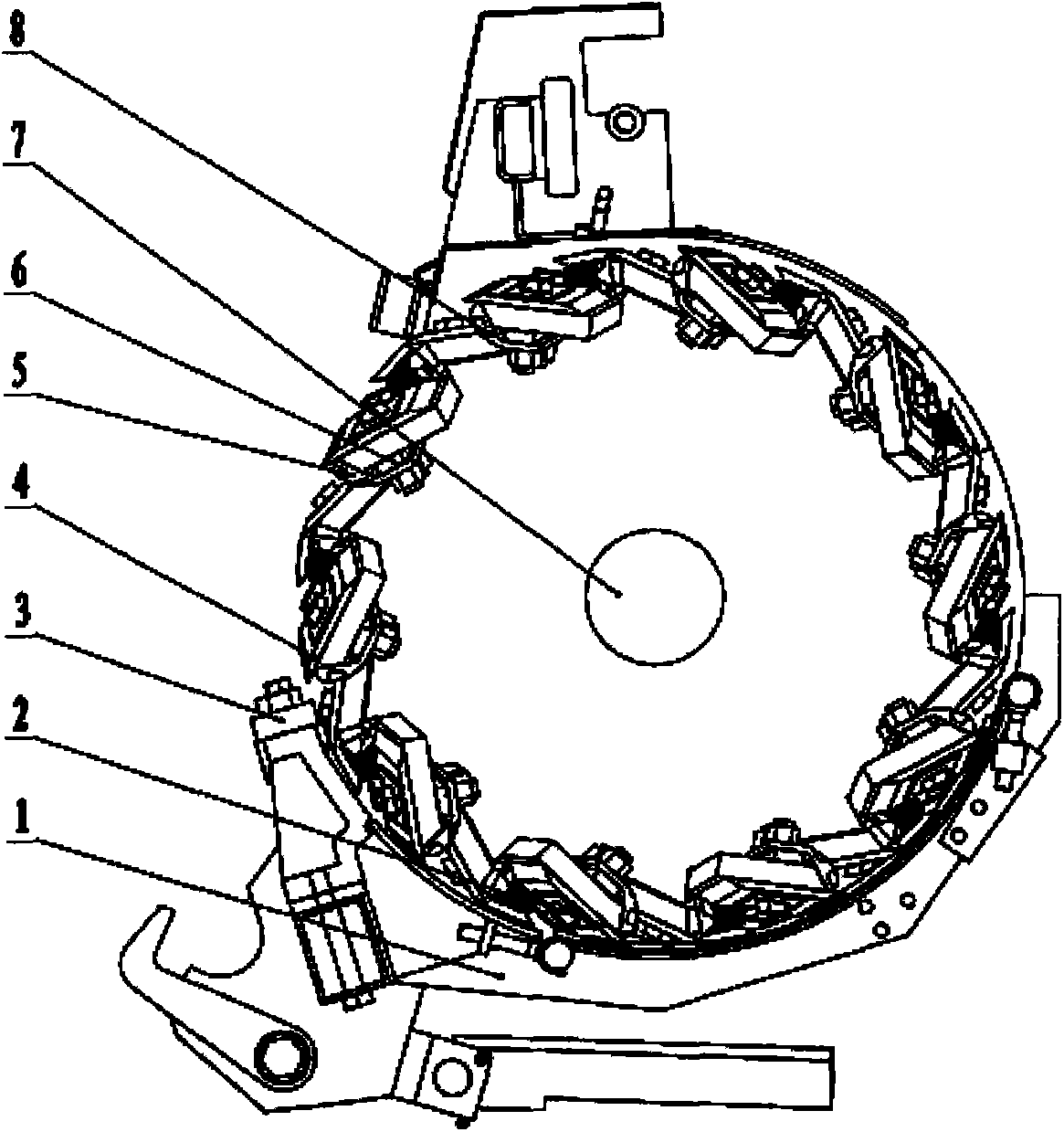

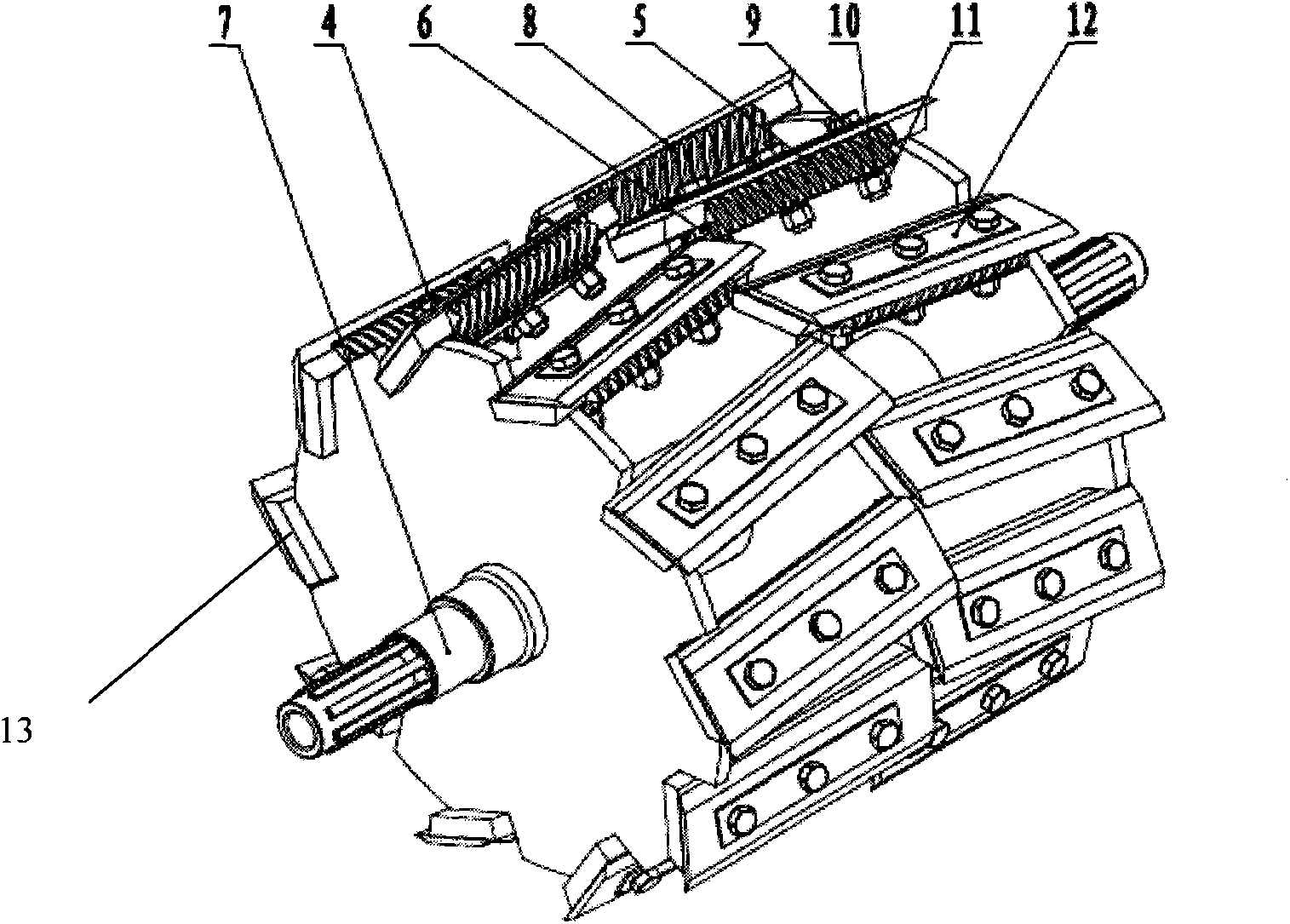

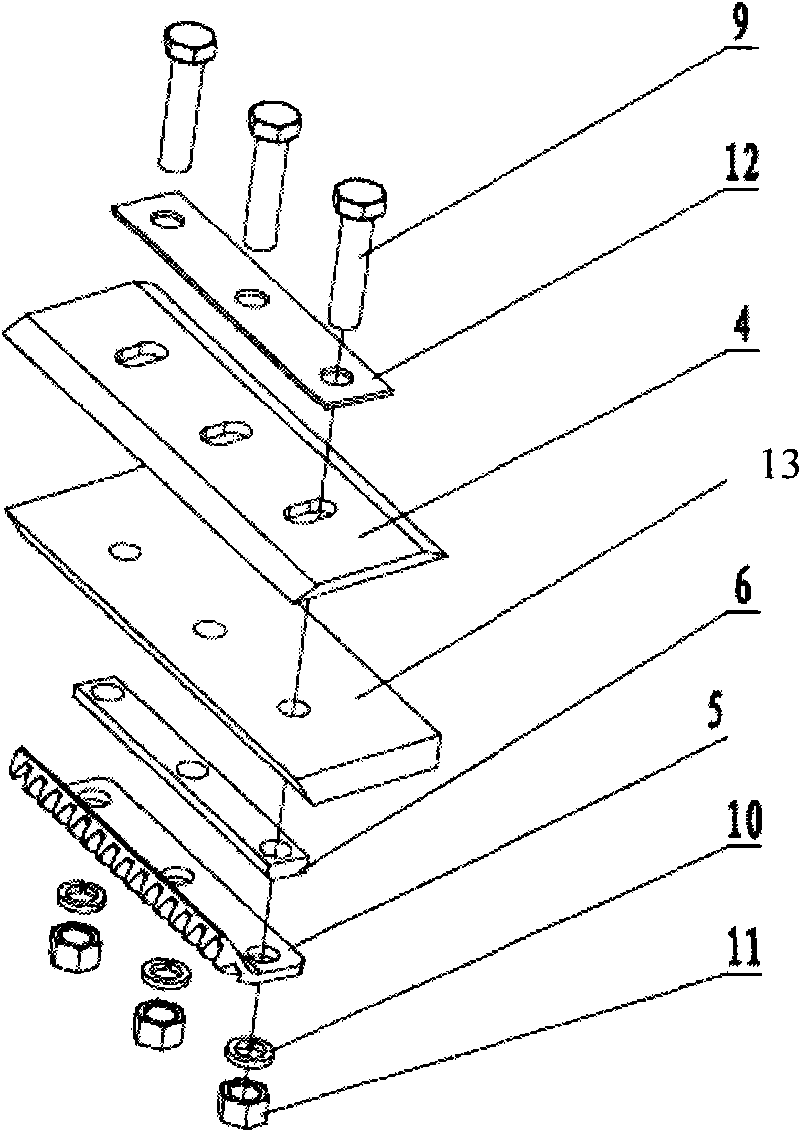

[0019] Such as Figure 1 to Figure 5 As shown, the chopping and kneading device of the silage harvester of the present invention includes a chopping mechanism and a kneading mechanism, and the chopping mechanism includes a chopping drum shell (1), a chopping machine arranged in the chopping drum shell (1). The drum (7), the fixed knife seat fixedly connected to the shell of the shredding drum (1), the movable knife seat (13) fixedly connected to the left and right sides of the shredding drum (7) and arranged crosswise in a herringbone shape ; The fixed knife seat is fixedly connected with a fixed knife (3), and the movable knife seat (4) is fixedly connected with a movable knife (4) by a bolt (9), a spring washer (10), a nut (11), and a gasket (12). ); the moving knife (4) is fixedly connected to the upper end of the moving knife seat (13); the kneading mechanism includes a friction block, an intermediate pad (6) and a concave plate (2); the friction block is fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com