An external-layer fabric of fire-fighting heat-insulating protective clothing

A protective clothing and outer layer technology, which is applied in the field of layered structure of outer layer fabrics and fabrics of fire-fighting heat insulation protective clothing, can solve the problem of large local stress between the aluminum-plated carrier layer and the base fabric layer, and uneven distribution of overall stiffness/flexibility , heat radiation resistance decline and other problems, to achieve good anti-radiation heat penetration performance, local stress reduction, good effect of reflecting radiant heat function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

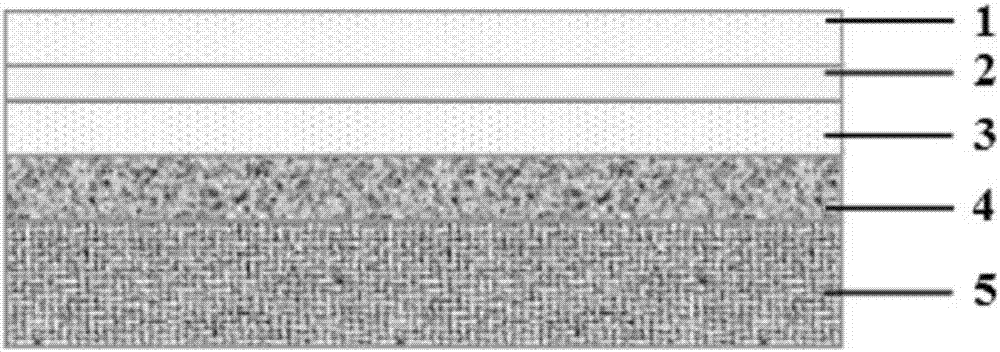

[0030] see figure 1 , a kind of outer layer fabric of fire-fighting heat-insulating protective clothing, comprise the first aluminized layer 1, high temperature resistant polymer film layer 2, the second aluminized layer 3, bonding glue layer 4, base cloth layer 5; Said first The aluminum-coated layer 1 and the second aluminum-coated layer 3 are plated on both sides of the high-temperature-resistant polymer film layer 2 , and the second aluminum-coated layer 3 and the base cloth layer 5 are bonded by an adhesive layer 4 .

[0031] In this embodiment, the adhesive layer 4 is a high-temperature flame-retardant adhesive.

[0032] see figure 1 , in this embodiment, the high temperature resistant polymer film layer 2 is PVC film, PET film or PTFE film.

[0033] In this embodiment, the high-temperature flame-retardant adhesive is an inorganic polymer adhesive made of aluminum phosphate, magnesium silicate, sodium silicate, fireproofing agent, and inorganic polymer polymerizer.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com