Modified inorganic decorative sheet and preparation method thereof

A decorative sheet and inorganic technology, applied in the field of building decoration materials, can solve problems such as danger, complicated construction technology, and difficult renovation, and achieve the effects of good elasticity and flexibility, superior fire resistance, and simplified manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

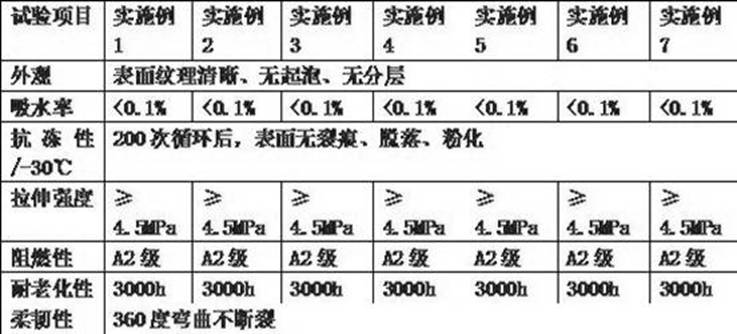

Examples

Embodiment 1

[0032] (1) At room temperature, add 10 parts of acrylic emulsion, 15 parts of water, 0.5 parts of colorant, 0.1 part of dispersant, 0.1 part of polyvinyl alcohol fiber and 0.008 part of cellulose into the reactor, stir for 60 min, add inorganic powder for 30 part and 50 parts of stone sand, stirred for 100 min, then added 0.1 part of defoamer and 0.2 part of water repellent, stirred for 120 min until uniformly mixed, and modified inorganic slurry was obtained;

[0033] (2) Spray the prepared modified inorganic slurry evenly on the surface of the silica gel mold. The surface of the silica gel is provided with a predetermined texture, and the spraying thickness is controlled at 3 mm to form a decorative layer;

[0034] (3) Heat and cure the silicone mold sprayed with slurry at 80°C until the decorative layer presents a star-shaped semi-cured state;

[0035] (4) Lay a layer of glass fiber grid on the top of the semi-cured veneer layer, and then spray the slurry prepared in step (...

Embodiment 2

[0038] (1) At room temperature, add 20 parts of acrylic emulsion, 10 parts of water, 0.1 part of colorant, 0.3 part of dispersant, 0.009 part of polyvinyl alcohol fiber and 0.005 part of cellulose into the reactor, stir for 80 min, and add inorganic powder for 35 part and 60 parts of stone sand, stirred for 120 min, then added 0.3 part of defoamer and 0.4 part of water repellent, stirred for 100 min until uniformly mixed, and modified inorganic slurry was obtained;

[0039] (2) Spray the prepared modified inorganic slurry evenly on the surface of the silicone mold, the surface of the silicone is provided with a predetermined texture, and the spraying thickness is controlled at 2.5mm to form a decorative layer;

[0040] (3) Heat and cure the silicone mold sprayed with slurry at 100°C until the decorative layer presents a star-shaped semi-cured state;

[0041] (4) Lay a layer of glass fiber grid on the top of the semi-cured veneer layer, and then spray the slurry prepared in ste...

Embodiment 3

[0044] (1) At room temperature, add 30 parts of acrylic emulsion, 18 parts of water, 1 part of colorant, 0.2 part of dispersant, 0.007 part of polyvinyl alcohol fiber and 0.01 part of cellulose into the reactor, stir for 100 min, add inorganic powder for 40 part and 80 parts of stone sand, stirred for 90 min, then added 0.2 part of defoamer and 0.6 part of water repellent, stirred for 80 min until uniformly mixed, and modified inorganic slurry was prepared;

[0045] (2) Evenly spray the prepared modified inorganic slurry on the surface of the silica gel mold, the surface of the silica gel is provided with a predetermined texture, and the spraying thickness is controlled at 2 mm to form a decorative layer;

[0046] (3) Heat and cure the silicone mold sprayed with slurry at 120°C until the decorative layer presents a star-shaped semi-cured state;

[0047] (4) Lay a layer of glass fiber grid on the top of the semi-cured veneer layer, and then spray the slurry prepared in step (1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com