Preparation method of amorphous alloy mold and application thereof in micro-flow groove forming

A technology of amorphous alloy and micro-fluid, which is applied in the field of hot-press forming of amorphous alloy mould, to achieve batch precision replication, save production cost, good surface quality and dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0040] A preparation method of an amorphous alloy mould, comprising the steps of:

[0041] (1) Silicon mold preparation

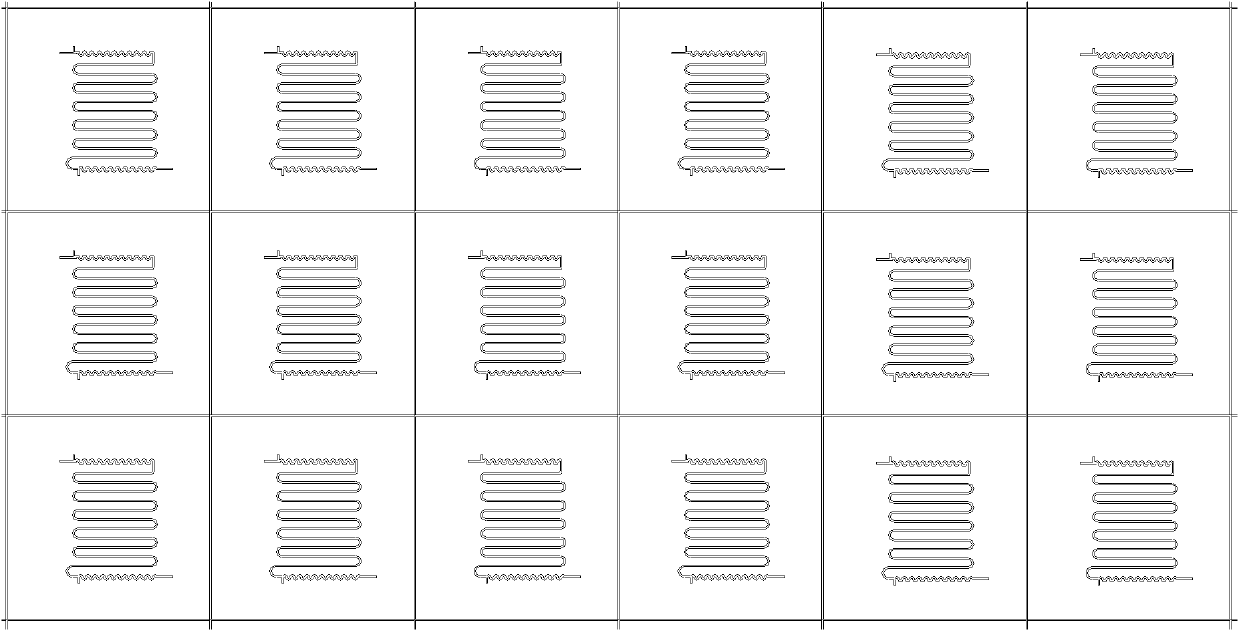

[0042] The designed micro-channel pattern is etched on the silicon chip with deep reactive ion etching technology to etch a micro-channel female master mold with concave channels. A silicon mold containing a single microfluidic female master mold with a length and width of 5 mm was cut out, washed with acetone and dried. In this example, a silicon mold containing a single microfluidic female master mold is cut out, and a silicon mold containing multiple microfluidic female female molds can also be cut out.

[0043] (2) Preparation of amorphous alloy samples

[0044] Select a Zr-Be based amorphous alloy system with high brittleness value, wide supercooled liquid region, low glass transition temperature, and high temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com