Preparation process of a high strain rate superplastic rare earth magnesium alloy

A technology with high strain rate and preparation technology, which is applied in the field of preparation technology of high strain rate superplastic rare earth magnesium alloy, can solve the problems of inability to achieve high strength and high plasticity, and decrease elongation, so as to reduce processing cost and increase elongation , The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

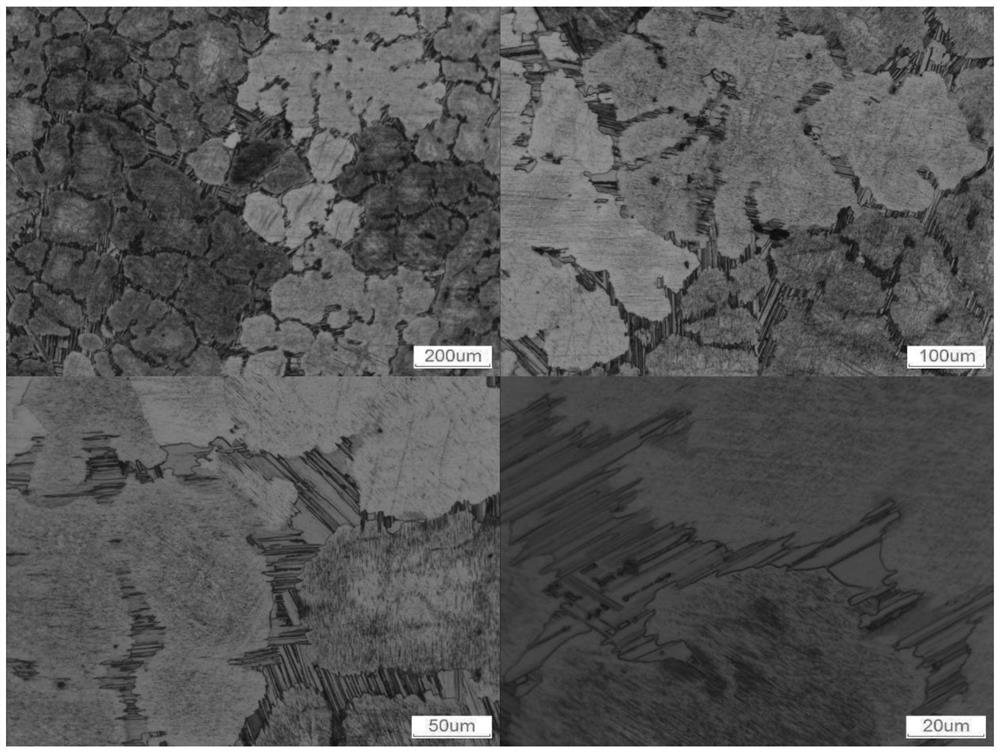

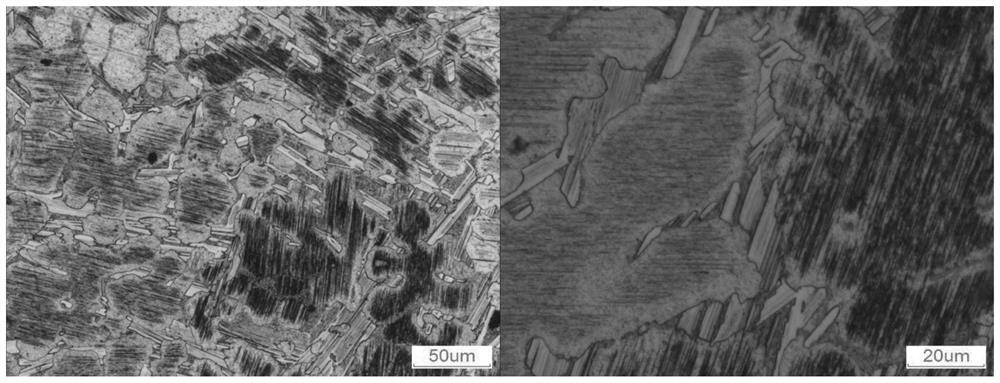

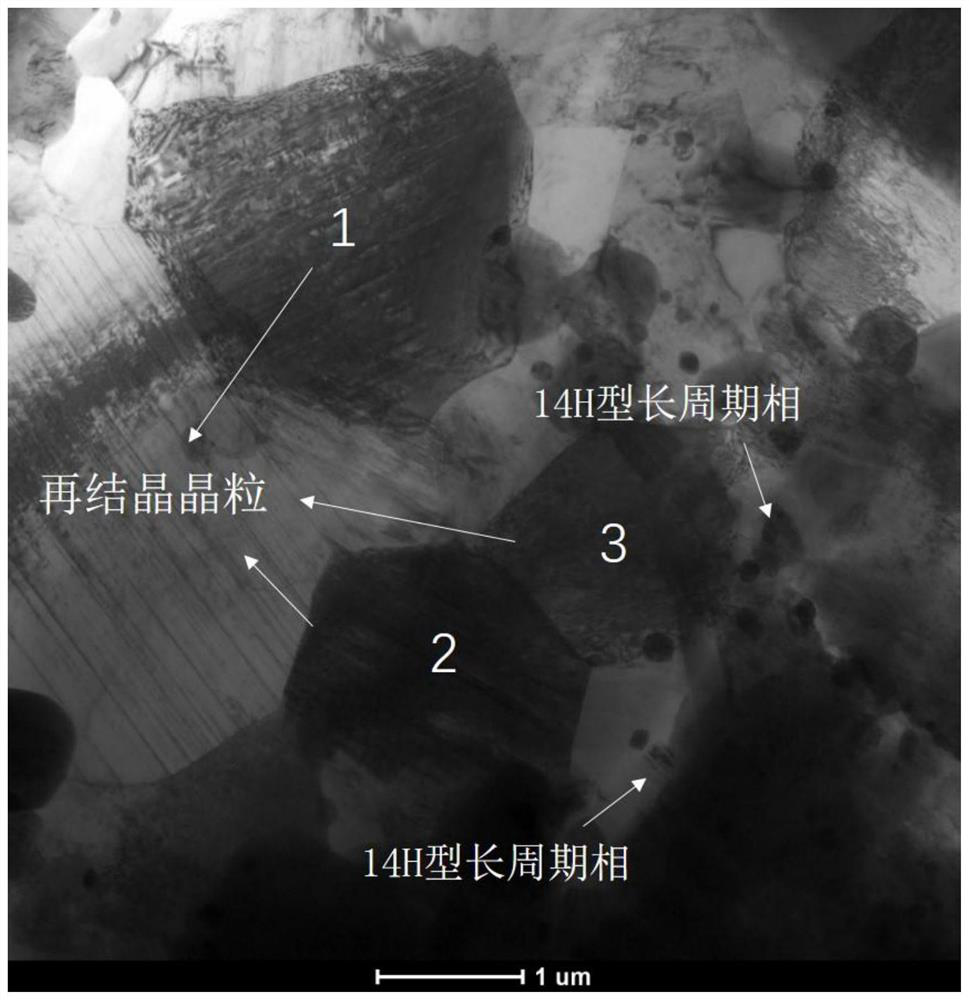

Embodiment 1

[0037]Preparation of low temperature high strain rate superplastic rare earth magnesium alloy. With pure magnesium (99.95wt%), Mg-20Er (wt%), Mg-30Y (wt%), pure zinc (99.95wt%) in the ratio of 37:10:18:2 as raw material in CO 2 (99vol%) and SF 6 (1vol%) melting at 700°C under a protective atmosphere of mixed gas to obtain rare earth magnesium alloy Mg-8Y-2Er-3Zn, and then pouring water cooling to obtain the original cast rare earth magnesium alloy, and the obtained original grain size is 150-160 μm; Cut out a cuboid ECAP sample with a size of 50×20×20mm by using a wire electric discharge machine; after the block sample is fully isolated from the air, it is buried and compacted with graphite, and placed in a constant temperature timing horse boiling furnace for 12h solidification at 500°C. Dissolution treatment; keep warm and heat the ECAP mold to 400°C, then put the magnesium alloy sample uniformly coated with graphite emulsion into the mold and keep it warm for 10 minutes, a...

Embodiment 2

[0039] With pure magnesium (99.95wt%), Mg-20Er (wt%), Mg-30Y (wt%), pure zinc (99.95wt%) in the ratio of 37:10:18:2 as raw material in CO 2 (99vol%) and SF 6 (1vol%) melting at 700°C under a protective atmosphere of mixed gas to obtain rare earth magnesium alloy Mg-8Y-2Er-3Zn, and then pouring water cooling to obtain the original cast rare earth magnesium alloy, and the obtained original grain size is 150-160 μm; Cut out a cuboid ECAP sample with a size of 50×20×20mm by using a wire electric discharge machine; after the block sample is fully isolated from the air, it is buried and compacted with graphite, and placed in a constant-temperature timing horse-boiler for 10 hours of solidification at 500°C. Dissolution treatment; keep warm and heat the ECAP mold to 400°C, then put the magnesium alloy sample uniformly coated with graphite milk into the mold and keep it warm for 10 minutes, and then perform 32 passes of ECAP processing; the sample after ECAP processing is processed by...

Embodiment 3

[0041] Preparation of low temperature high strain rate superplastic rare earth magnesium alloy. With pure magnesium (99.95wt%), Mg-20Er (wt%), Mg-30Y (wt%), pure zinc (99.95wt%) in the ratio of 37:10:18:2 as raw material in CO 2 (99vol%) and SF 6 (1vol%) melting at 700°C under a protective atmosphere of mixed gas to obtain rare earth magnesium alloy Mg-8Y-2Er-3Zn, and then pouring water cooling to obtain the original cast rare earth magnesium alloy, and the obtained original grain size is 150-160 μm; Cut out a cuboid ECAP sample with a size of 50×20×20mm by using a wire electric discharge machine; after the block sample is fully isolated from the air, it is buried and compacted with graphite, and placed in a constant-temperature timing horse-boiler for 10 hours of solidification at 495°C. Dissolution treatment; keep warm and heat the ECAP mold to 380°C, then put the magnesium alloy sample uniformly coated with graphite emulsion into the mold and keep it warm for 10 minutes, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com