A kind of preparation method of nickel-manganese-gallium alloy with superplasticity

A technology of nickel-manganese-gallium and superplasticity, which is applied in the field of nickel-manganese-gallium alloy preparation, can solve the problems of high deformation resistance and difficulty in forming nickel-manganese-gallium alloys, and achieve the effects of improving forming efficiency, good application prospects, and reducing forming costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

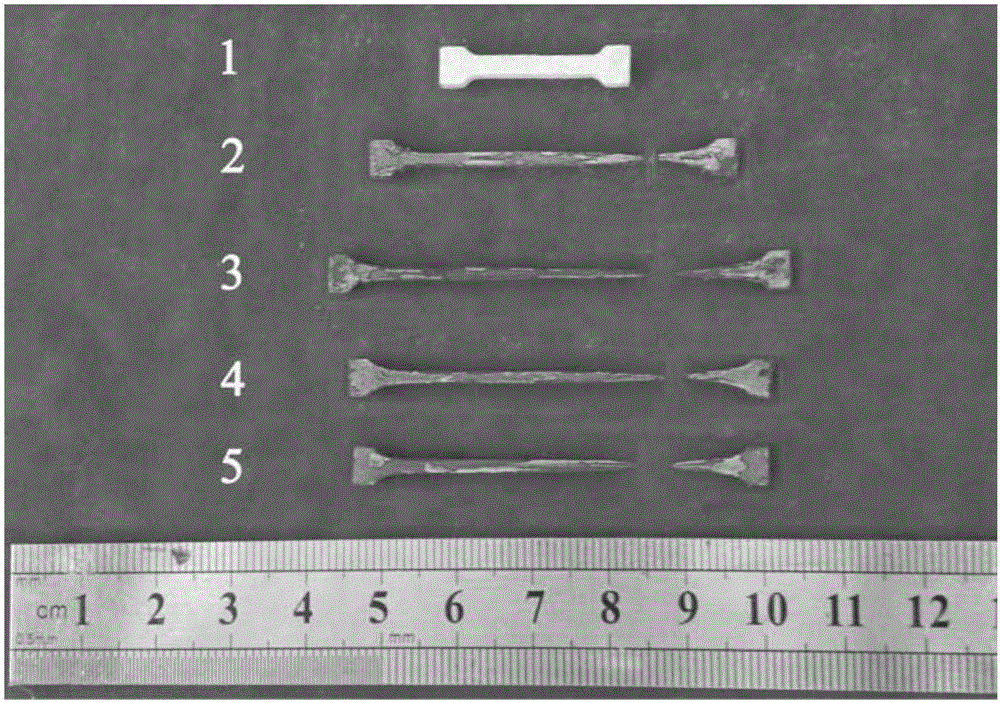

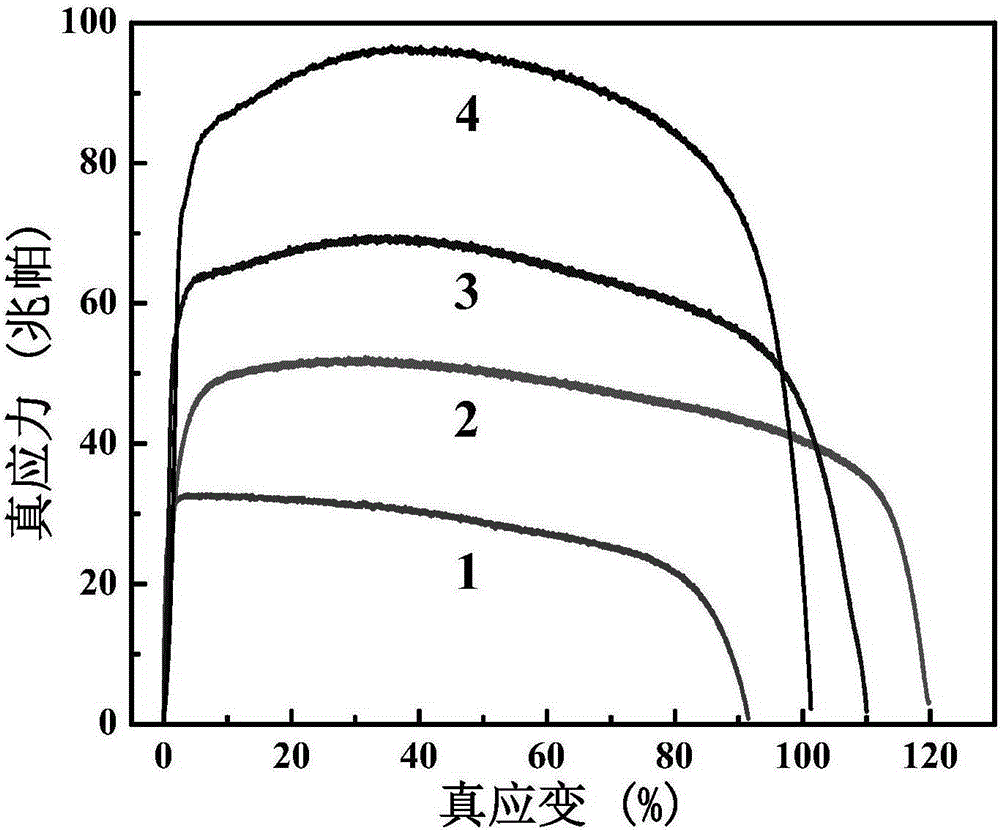

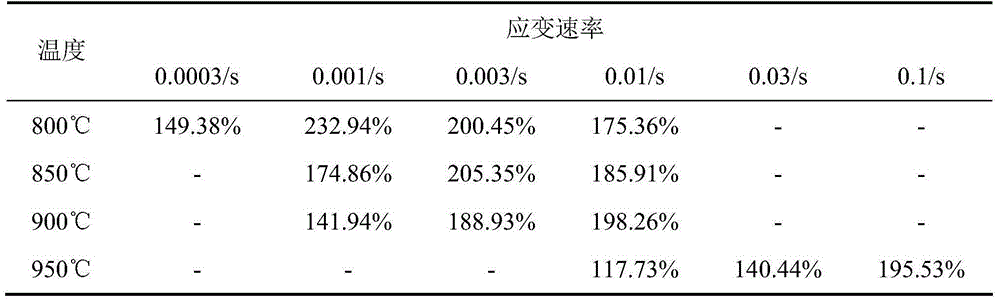

[0016] Embodiment 1: The preparation method of a superplastic nickel-manganese-gallium alloy described in this embodiment is specifically carried out according to the following steps:

[0017] 1. Preparation of nickel-manganese-gallium alloy: firstly weigh pure nickel, pure manganese and pure gallium according to the atomic percentage of 45% to 55% nickel, 25% to 35% manganese and 15% to 25% gallium, and then use vacuum induction melting method Preparation of nickel-manganese-gallium alloys with a diameter greater than 150 mm and a height greater than 100 mm;

[0018] 2. Homogenization heat treatment: use electric spark to cut the nickel-manganese-gallium alloy prepared in step 1 into a cylindrical blank with a diameter of 60mm-150mm and a height of 40mm-100mm, then place the cylindrical blank in acetone and clean it under the action of ultrasonic waves 15min to 30min, then put the cleaned cylindrical blank in an oven at a temperature of 80°C to 120°C for drying, and finally p...

specific Embodiment approach 2

[0025] Embodiment 2: This embodiment differs from Embodiment 1 in that the sheathing material described in step 3 is a metal material with low yield strength at high temperature and good plasticity. . Others are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the sheathing material is low carbon steel, stainless steel or brass. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com