A kind of nb‑si‑ti‑mo‑b alloy plate and preparation method thereof

An alloy sheet, nb-si-ti-mo-b technology, applied in the field of Nb-Si-Ti-Mo-B alloy sheet and its preparation, can solve the problem of reducing the high-temperature tensile strength of alloy materials, difficult to process and form, and fracture Low toughness and other problems, to achieve the effect of improving room temperature plastic toughness, reducing density, and improving room temperature plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

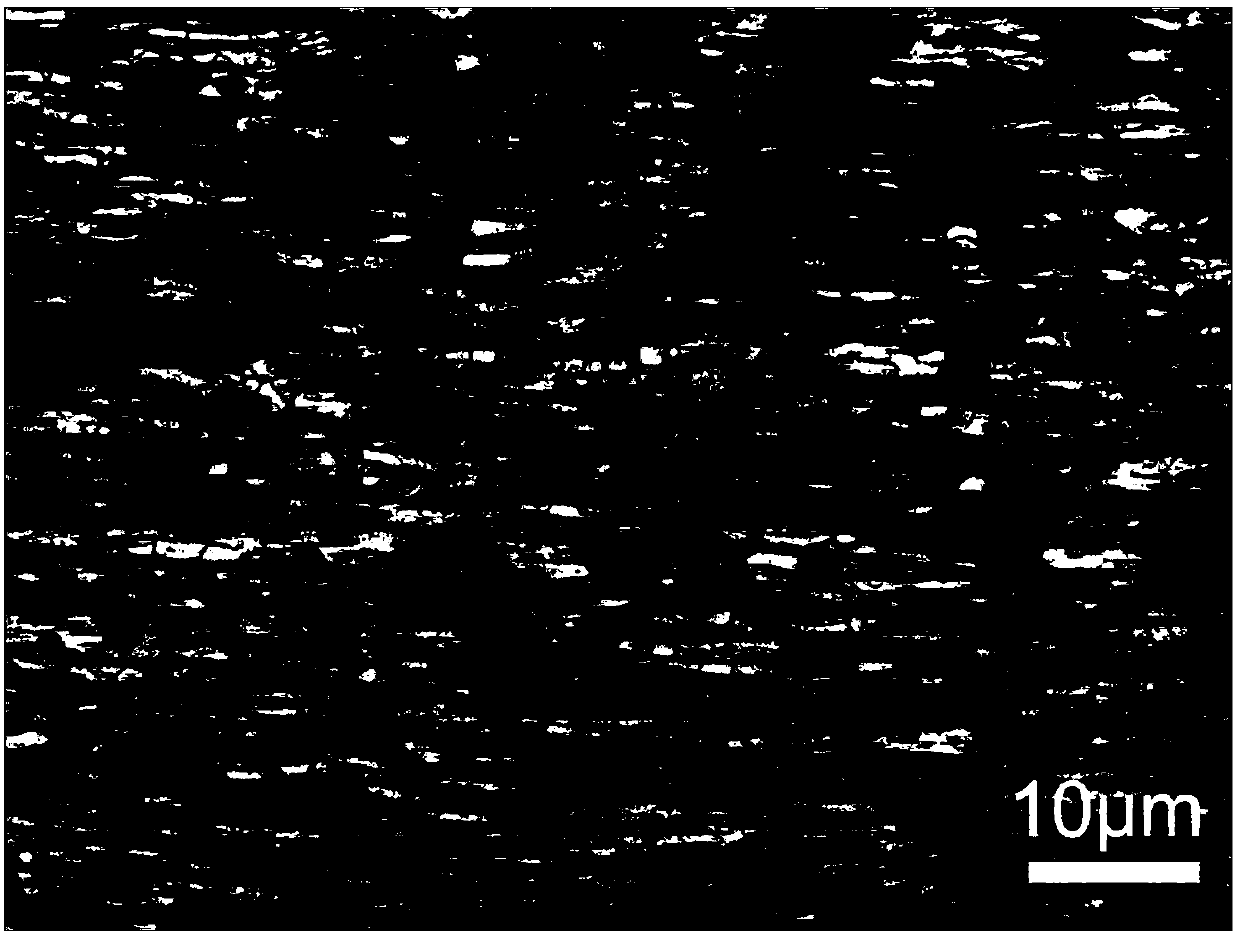

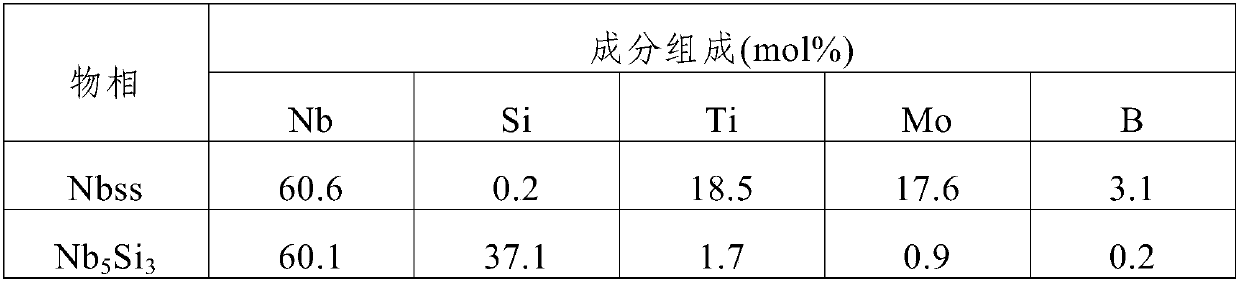

[0028] The Nb-Si-Ti-Mo-B alloy sheet of this embodiment is composed of the following atomic percentages: Si 13%, Ti 10%, Mo 8%, B 1.5%, and the balance is Nb and unavoidable impurities.

[0029] The preparation method of the Nb-Si-Ti-Mo-B alloy sheet of this embodiment includes the following steps:

[0030] Step 1. Place Si powder, Ti powder, Mo powder, B powder and Nb powder in a ball mill, using absolute ethanol as a dispersant, and wet ball milling at a speed of 200 rpm and a ball-to-material mass ratio of 6:1 15h, after ball milling, drying under vacuum conditions to obtain mixed powder; the volume of the absolute ethanol is 4 times the sum of the mass of Si powder, Ti powder, Mo powder, B powder and Nb powder, and the unit of volume is mL , The unit of mass is g, the mass purity of the Si powder, Ti powder, Mo powder, B powder and Nb powder is not less than 99%, the particle size of the Si powder is not more than 10 μm, and the particle size of the Ti powder Not more than 20 ...

Embodiment 2

[0042] The Nb-Si-Ti-Mo-B alloy sheet of this embodiment is composed of the following atomic percentages: Si 10%, Ti 8%, Mo 6%, B 1%, and the balance is Nb and unavoidable impurities.

[0043] The preparation method of the Nb-Si-Ti-Mo-B alloy sheet of this embodiment includes the following steps:

[0044] Step 1. Put Si powder, Ti powder, Mo powder, B powder and Nb powder in a ball mill, use absolute ethanol as a dispersant, wet ball mill at a speed of 100 rpm and a ball-to-material mass ratio of 4:1 10h, after ball milling, drying under vacuum conditions to obtain mixed powder; the volume of the absolute ethanol is 3 times the sum of the mass of Si powder, Ti powder, Mo powder, B powder and Nb powder, and the unit of volume is mL , The unit of mass is g, the mass purity of the Si powder, Ti powder, Mo powder, B powder and Nb powder is not less than 99%, the particle size of the Si powder is not more than 10 μm, and the particle size of the Ti powder Not more than 20 μm, the partic...

Embodiment 3

[0051] The Nb-Si-Ti-Mo-B alloy sheet of this embodiment is composed of the following atomic percentages: Si 16%, Ti 12%, Mo 10%, B 2%, and the balance is Nb and unavoidable impurities.

[0052] The preparation method of the Nb-Si-Ti-Mo-B alloy sheet of this embodiment includes the following steps:

[0053] Step 1. Place Si powder, Ti powder, Mo powder, B powder and Nb powder in a ball mill, using anhydrous ethanol as a dispersant, and wet ball milling at a speed of 100 rpm and a ball-to-material mass ratio of 8:1 20h, after ball milling, drying under vacuum conditions to obtain mixed powder; the volume of the absolute ethanol is 5 times the sum of the mass of Si powder, Ti powder, Mo powder, B powder and Nb powder, and the unit of volume is mL , The unit of mass is g, the mass purity of the Si powder, Ti powder, Mo powder, B powder and Nb powder is not less than 99%, the particle size of the Si powder is not more than 10 μm, and the particle size of the Ti powder Not more than 20 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com