An energy-saving anti-wear hydraulic oil

An anti-wear hydraulic oil and energy-saving technology, which is applied in the petroleum industry, lubricating compositions, additives, etc., can solve problems such as unstable viscosity-temperature performance, insufficient anti-wear performance, and large viscosity changes, and achieve good energy-saving performance, Excellent corrosion resistance, little effect of swelling and shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

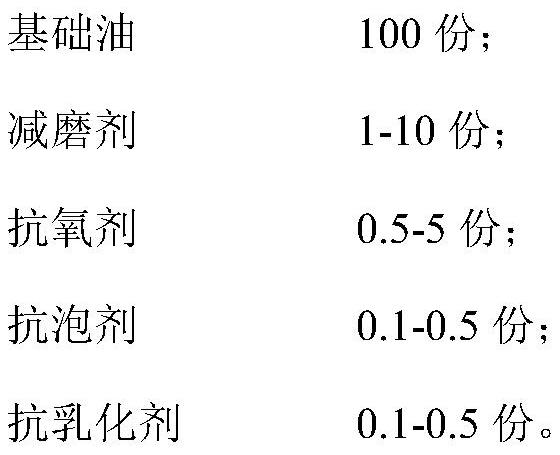

[0028] As an embodiment of the present invention, in parts by weight, the anti-wear hydraulic composition includes:

[0029]

[0030]

[0031] base oil

[0032] In the present invention, the base oil is selected from base oils of mineral oil, synthetic oil and mixtures thereof.

[0033] As an embodiment of the present invention, the mineral oil is selected from Group III mineral oils.

[0034] As an embodiment of the present invention, the synthetic base oil is selected from one or more of PAO synthetic oil, ester synthetic oil, and polyether synthetic oil.

[0035] The advantages of ester oil: the oxidation stability and thermal stability of the inhibitor are better than that of mineral oil, the use temperature is high, the pour point is low, and the low temperature fluidity is good; the viscosity temperature performance is good, and it can be synthesized with mineral oil and other kinds Oil miscible, good anti-wear, anti-chafe properties; low volatility, non-toxic, ...

Embodiment 1

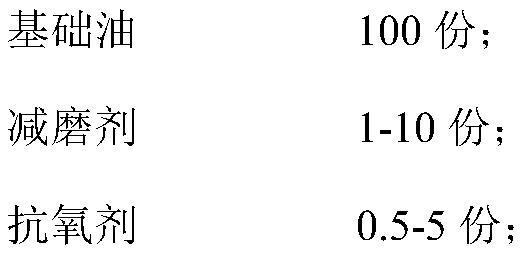

[0082] Embodiment 1: This embodiment provides an energy-saving anti-wear hydraulic oil, which includes:

[0083]

[0084]

[0085] The base oil is a mixture of ester synthetic oil and Group III mineral oil at a weight ratio of 1:1; the ester synthetic oil is purchased from Dongxu Chemical Factory in Yingkou City, the brand is Kelubo, and the specification model is 4027.

[0086] The wear reducing agent is bis-octyl zinc salt of thiophosphor.

[0087] Described antioxidant is hindered phenol type antioxidant, and preparation method is as follows:

[0088] S01 Put 0.02mol 4-ethyl-3-hydroxybenzoic acid into a dry 250mL reactor, add 50mL chloroform, after dissolving, slowly add 4mL thionyl chloride dropwise under the protection of nitrogen, and then react at 50°C After 5h, the reaction was distilled under reduced pressure to remove the solvent and unreacted thionyl chloride to obtain the product 1;

[0089] S02 Add 0.002mol of polyamide-amine polymer, 7ml of distilled wate...

Embodiment 2

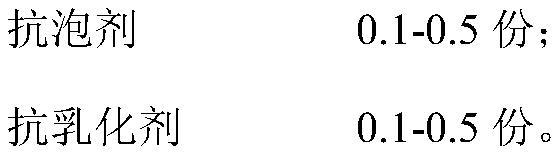

[0097] Example 2: The difference between the implementation of this example and Example 1 is that this example provides an energy-saving anti-wear hydraulic oil, which includes:

[0098]

[0099]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com