A high-throughput preparation method for superalloy materials

A high-temperature alloy, high-throughput technology, used in metal processing equipment, manufacturing tools, casting and molding equipment, etc., can solve problems such as the inability to achieve high-throughput preparation of components and structures, and achieve the realization of research and development costs and cycle, process design. Reasonable and practicable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In this embodiment, the nickel-based superalloy K417G alloy is used as the research object, and the composition of the alloy is shown in Table 1.

[0030] Table 1 Weight percent of main alloying elements in K417G alloy

[0031] C Cr co Mo Al Ti V B Zr Ni 0.15 9.0 10.0 3.0 5.5 4.5 0.7 0.015 0.07 Remain

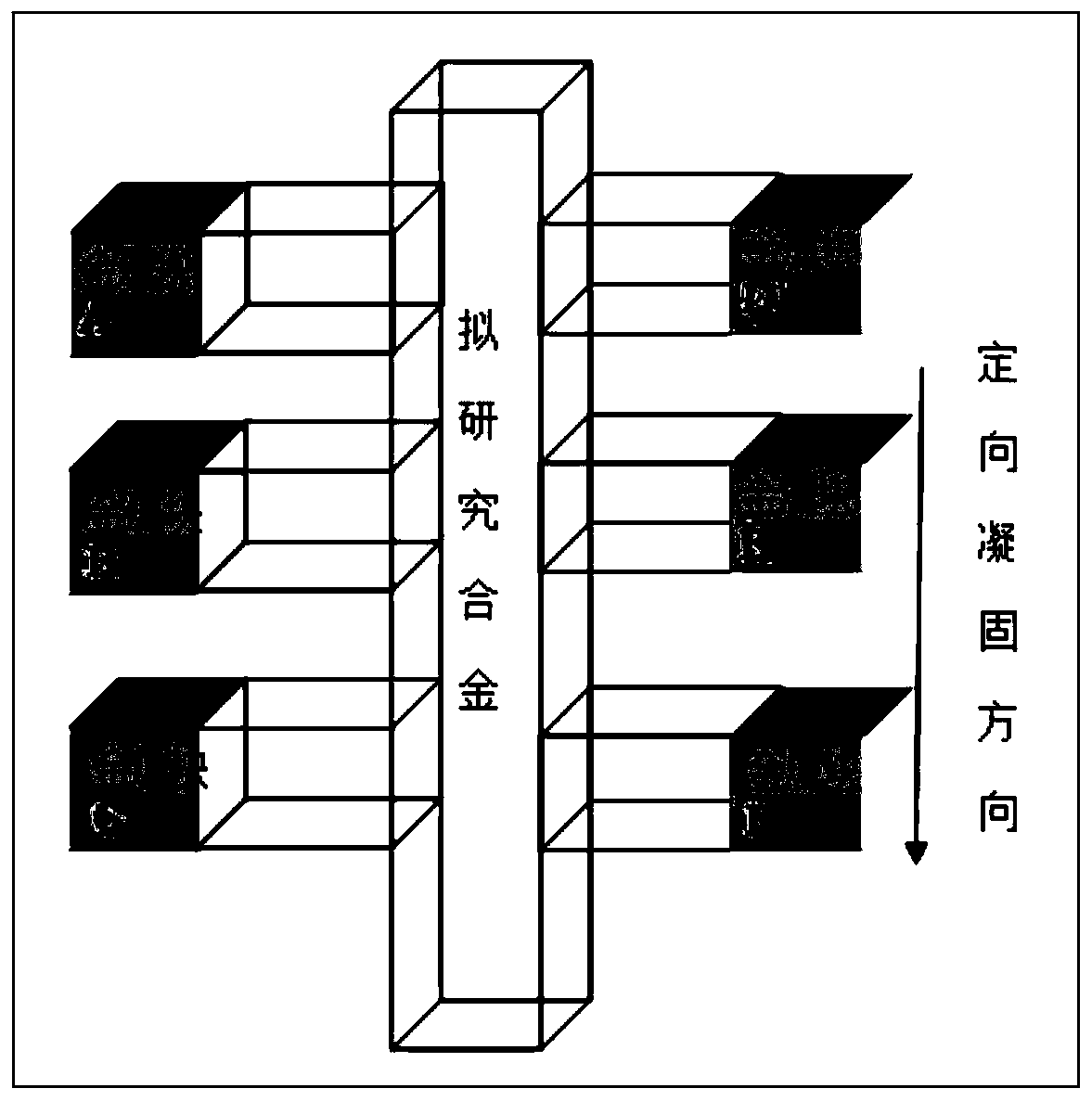

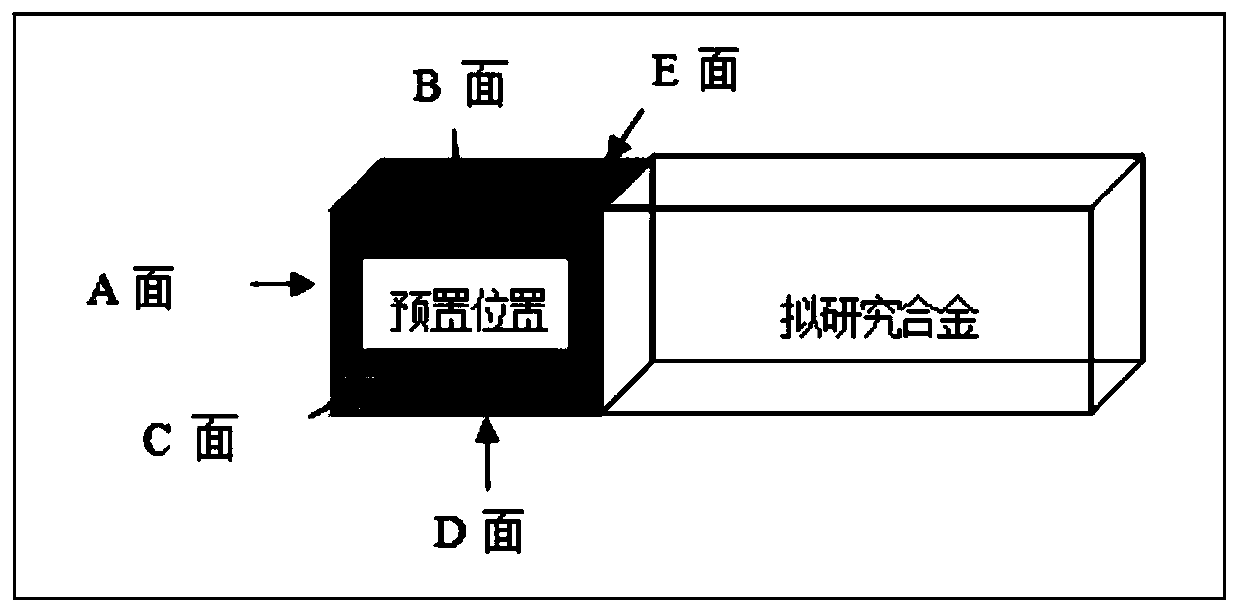

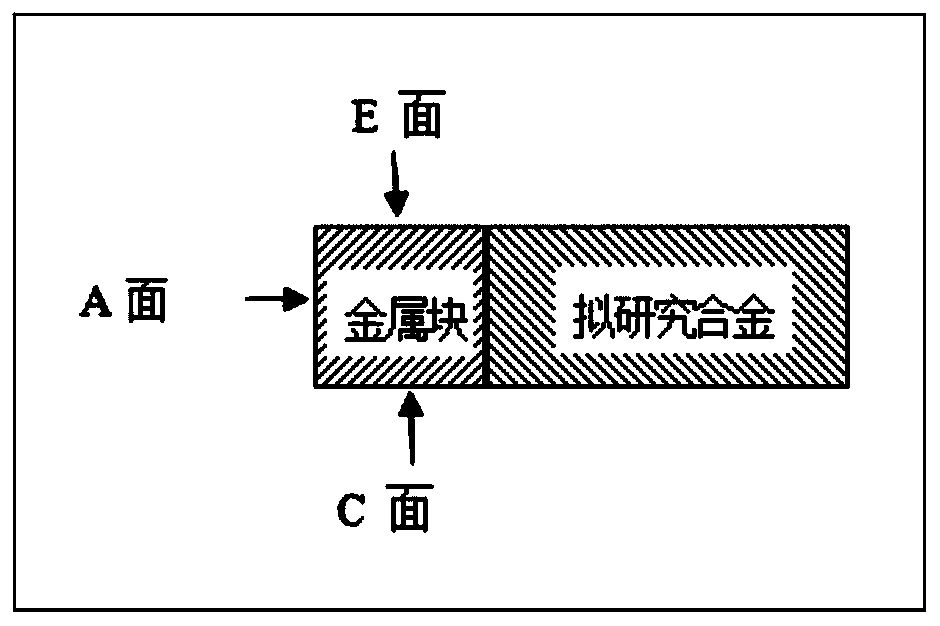

[0032] In this example, through the high-throughput preparation of superalloy materials, the influence of components on the alloy microstructure is studied. Melt the paraffin at 60°C, inject the molten paraffin into a pre-designed metal mold with a stepped shape through a wax injection machine, the wax injection pressure is 1MPa, and keep it at room temperature for 5min until the paraffin is completely solidified. Paste a tape with a size of 5×5mm to 15×15mm on the side A (see Figure 1(b)). The wax pattern is assembled completely, and the assembled wax pattern is made into a corundum mold shell by hanging paste method. After the ...

Embodiment 2

[0034] In this embodiment, the nickel-based superalloy K417G alloy is used as the research object, and the composition of the alloy is shown in Table 2.

[0035] Table 2 Weight percent of main alloying elements in K417G alloy

[0036] C Cr co Mo Al Ti V B Zr Ni 0.15 9.0 10.0 3.0 5.5 4.5 0.7 0.015 0.07 Remain

[0037] In this example, through the high-throughput preparation of superalloy materials, the influence of components on the alloy microstructure is studied. Melt the paraffin at 70°C, inject the molten paraffin into a pre-designed metal mold with a stepped shape through a wax injection machine, the wax injection pressure is 1.5MPa, and keep it at room temperature for 6 minutes until the paraffin is completely solidified. Paste a tape with a size of 5×5mm to 15×15mm on the surface of position B (see Figure 1(b)). The wax pattern is assembled completely, and the assembled wax pattern is made into a corundum mold shell by hanging th...

Embodiment 3

[0039] In this embodiment, the nickel-based superalloy K417G alloy is used as the research object, and the composition of the alloy is shown in Table 3.

[0040] Table 3 Weight percent of main alloying elements in K417G alloy

[0041] C Cr co Mo Al Ti V B Zr Ni 0.15 9.0 10.0 3.0 5.5 4.5 0.7 0.015 0.07 Remain

[0042] In this example, through the high-throughput preparation of superalloy materials, the influence of components on the alloy microstructure is studied. Melt the paraffin at 50°C, inject the molten paraffin into a pre-designed metal mold with a stepped shape through a wax injection machine, the wax injection pressure is 0.5MPa, and keep it at room temperature for 3 minutes until the paraffin is completely solidified. Paste a tape with a size of 5×5mm to 15×15mm on the surface of position C (see Figure 1(b)). Complete the combination of the wax pattern, and make the corundum mold shell by hanging the wax pattern. After the cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com