Perovskite mixed conductor material and preparation method thereof

A cathode material, the technology of the implementation mode, applied in the field of perovskite mixed conductor material and its preparation, can solve the problems of high operating temperature, obstruction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

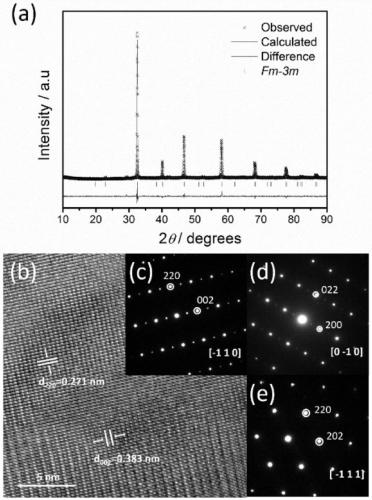

[0048] Example 1 Composite cathode material Sr for medium and low temperature solid oxide fuel cells 2 sc 0.1 Nb 0.1 co 1.5 Fe 0.3 o 6−δ preparation of

[0049] (1) Weigh 0.0691 g of scandium oxide, add 10 mL of concentrated nitric acid, then add 40 mL of deionized water, cover with a plastic film and heat to boil until transparent and clear.

[0050] (2) Weigh 4.2326 g of strontium nitrate, 4.3655 g of cobalt nitrate, 1.212 g of ferric nitrate, and 1.1632 g of niobium oxalate, add a small amount of deionized water to dissolve and mix with scandium nitrate solution. Weigh 11.7 g of ethylenediamine tetraacetic acid and 16.8 g of citric acid hydrate as a complexing agent and dissolve them in deionized water at a molar ratio of ethylenediaminetetraacetic acid: hydrated citric acid: total metal ions of 1:2:1.

[0051] (3) After adding the solution containing complexing agent to the solution containing metal ions, add an appropriate amount of ammonia water dropwise to make th...

Embodiment 2

[0054] Example 2 Preparation of symmetrical battery

[0055] (1) Weigh 1 g of the cathode powder Sr prepared in Example 1 2 sc 0.1 Nb 0.1 co 1.5 Fe 0.3 o 6−δ , 10 ml of isopropanol, 2 ml of ethylene glycol, and 0.8 ml of glycerol were poured into a high-energy ball mill, and after ball milling at 400 r / min for 30 min, they were transferred to a strain bottle with a straw to obtain the desired Cathode slurry.

[0056] (2) Place the prepared BZCYYb electrolyte on a heating platform to preheat at 200 °C, and use a spray gun to spray the prepared cathode slurry evenly on both sides of the electrolyte under the push of an inert gas. After the liquid is completely volatilized, The sprayed electrolyte was placed in a high-temperature muffle furnace and calcined at 900 °C for 2 h to obtain the desired symmetrical battery, which was used for the cathode material at 500-700 ℃ Measurement of polarization resistance over temperature range. Among them, the battery is at 700 ℃ The ...

Embodiment 3

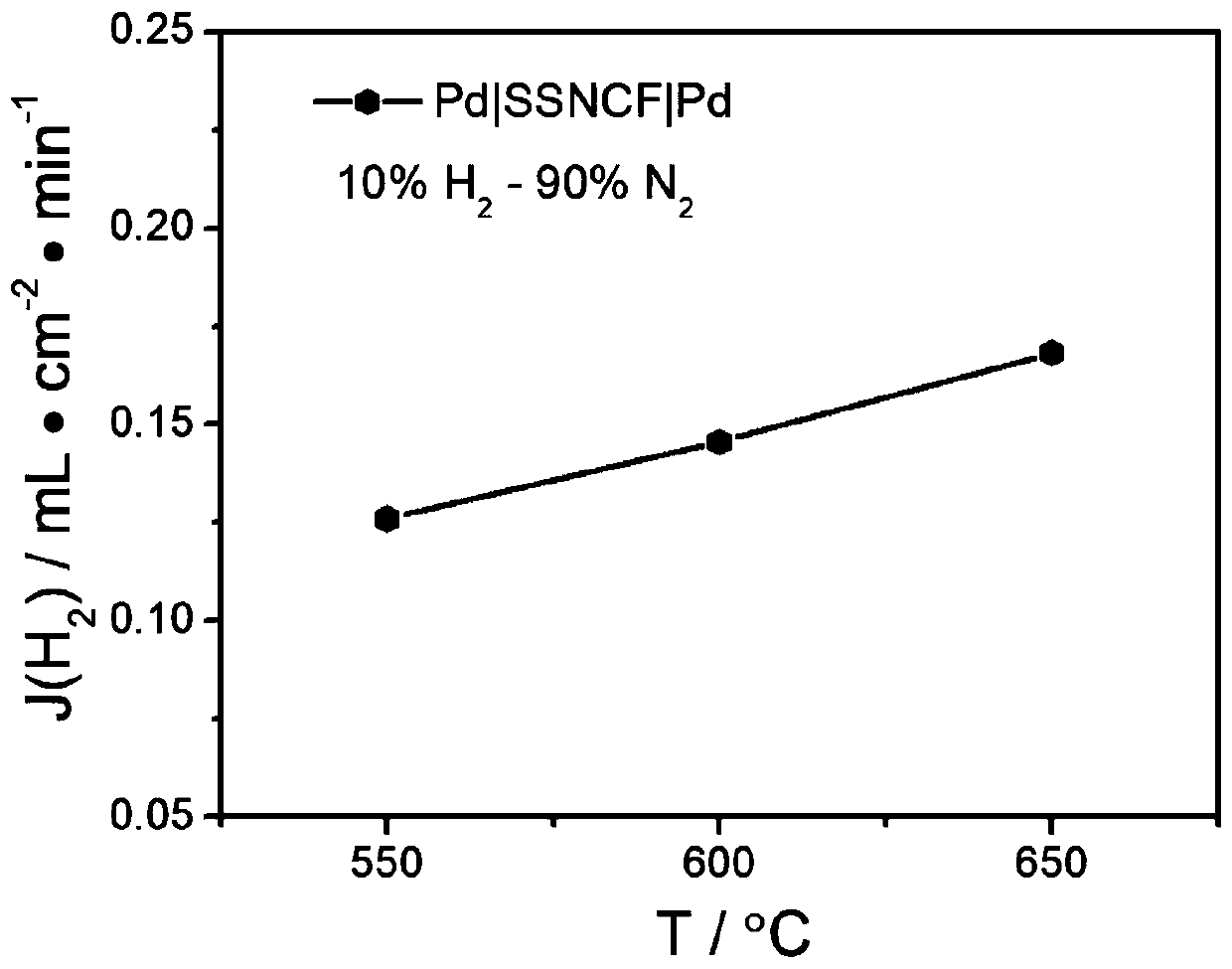

[0057] Example 3 Preparation of Single Cell

[0058] (1) Weigh 1 g of the cathode powder Sr prepared in Example 1 2 sc 0.1 Nb 0.1 co 1.5 Fe 0.3 o 6−δ , 10 ml of isopropanol, 2 ml of ethylene glycol, and 0.8 ml of glycerol were poured into a high-energy ball mill, and after ball milling at 400 r / min for 30 min, they were transferred to a strain bottle with a straw to obtain the desired Cathode slurry.

[0059] (2) Place the prepared dry-pressed battery sheet on a heating table to preheat at 200 °C, and use a spray gun to spray the prepared cathode slurry evenly on the electrolyte surface of the dry-pressed sheet under the push of an inert gas. After the liquid is completely evaporated, the sprayed dry-pressed battery is placed in a high-temperature muffle furnace and calcined at 900 °C for 2 hours to obtain the desired symmetrical battery, which is used to measure the polarization impedance of the cathode material in the temperature range of 450-650 °C. test.

[0060] C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com