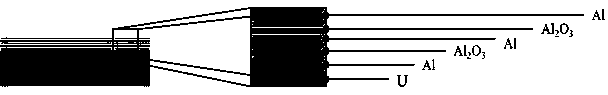

Metal uranium surface water-blocking hydrogen-blocking Al/Al2O3 composite plating layer and preparing method thereof

A technology of composite coating and metal uranium, applied in the direction of metal material coating process, coating, sputtering plating, etc., can solve problems affecting performance, corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

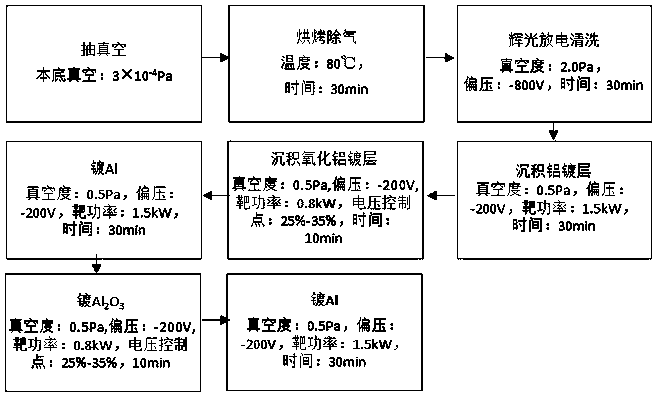

[0057] This example prepares 10 µm Al / Al on the surface of metal uranium 2 o 3 Composite coating, preparation process and process parameters such as figure 2 As shown, the preparation process is as follows.

[0058] 1) Substrate pretreatment

[0059] The oxide layer on the surface of the uranium metal was removed by mechanical grinding and polishing, and then the surface of the uranium metal from which the oxide layer was removed was cleaned with absolute ethanol, acetone, and dry nitrogen. Put the cleaned metal uranium into the vacuum chamber, use two magnetic levitation molecular pumps with a pumping speed of 2200L / s as the main pump, and work simultaneously with a cryopump with a pumping speed of 7500L / s to vacuum the vacuum chamber to 3×10 -4 Pa, and degas the vacuum chamber by baking, the baking temperature is 80°C, and the baking time is 30min. Subsequently, the vacuum chamber after baking was filled with high-purity argon to 2.0Pa, and a pulse bias of -800V was ap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com