Non-universal optical unit of submarine photoelectric composite cable and making method thereof

A photoelectric composite cable and the technology of its manufacturing method, which are applied in the direction of fiber mechanical structure, etc., can solve the problems of broken core of optical unit, optical unit cannot bear tension and side pressure, etc., and achieve compact structure, superior protection performance, and reliable manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

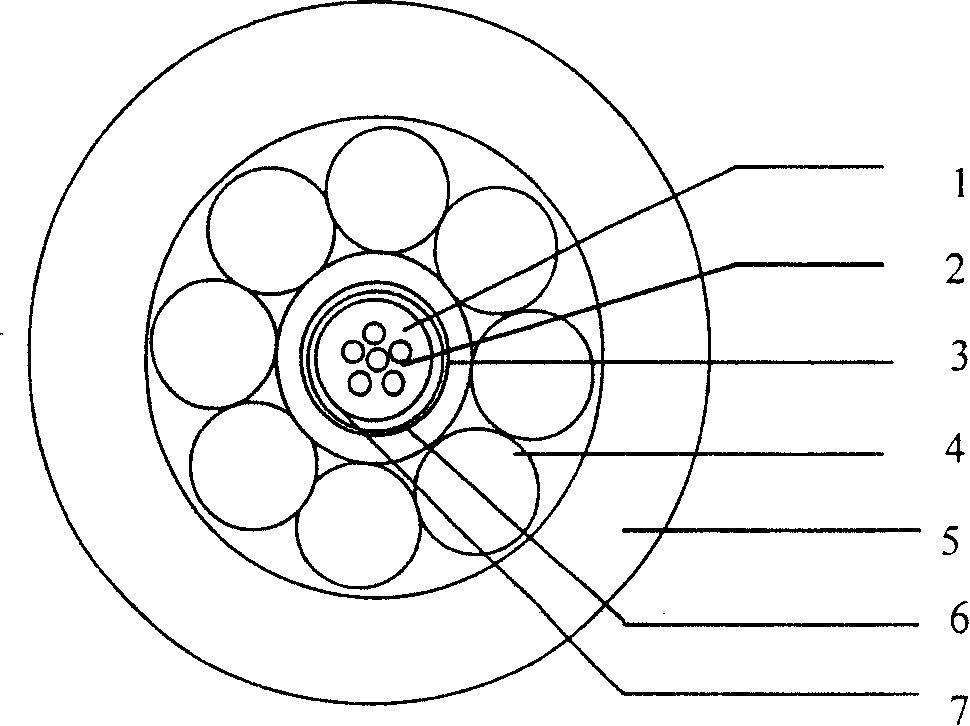

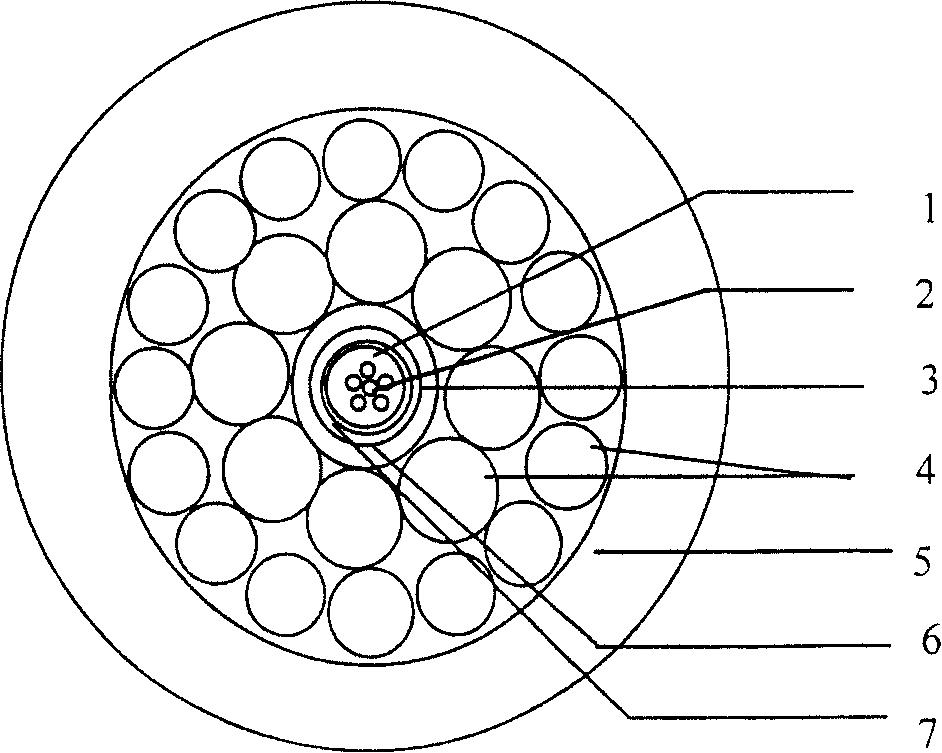

[0027] Refer to attached figure 1 , 2 The non-universal optical unit structure of the submarine photoelectric composite cable includes several optical fibers 2 , plastic tube 7 , hot melt adhesive layer 6 , stainless steel tube 3 , water blocking material 1 , high-strength armored steel wire 4 , and plastic protective layer 5 . A layer of plastic tube 7 is extruded outside several optical fibers 2, and the plastic tube 7 is filled with high water resistance material 1, and a layer of hot melt adhesive 6 is extruded outside the plastic tube 7, and a stainless steel tube 3 is made outside the plastic tube 7, and the stainless steel tube 3 One to two layers of high-strength armored steel wire 4 are armored on the outside, and a plastic protective layer 5 is extruded outside the high-strength armored steel wire 4 . The water-blocking material 1 can use water-blocking ointment, and the plastic protective layer 5 can use plastic materials such as polyethylene, nylon, and polyuretha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com