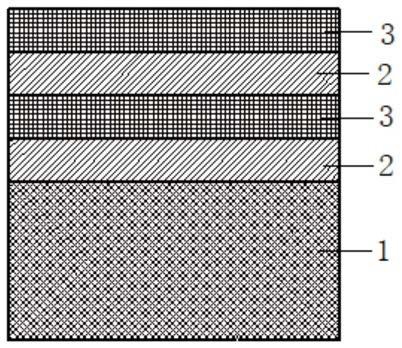

Composite proton conductive ceramic electrolyte film as well as preparation method and application thereof

A ceramic electrolyte, proton conduction technology, applied in circuits, fuel cells, electrical components, etc., can solve the problem of difficulty in preparing high-performance proton conductive ceramic electrolyte films, and achieve high density, excellent hydrogen barrier properties, and controllable thickness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) ZrO with a length of 60mm, an outer diameter of 15mm and a wall thickness of 2mm 2 Ultrasonic cleaning of ceramic tube surface for 15 minutes, drying;

[0028] (2) Preparation of SrCe on the surface of ceramic tubes by metal-organic chemical vapor deposition technology 1-x Yb x o 3-α thin film, the specific process parameters are: the reaction source is cerium acetylacetonate, strontium acetylacetonate, and ytterbium acetylacetonate, and the temperature of the reaction source is 350°C; H 2 The carrier gas flow rate is 200mL / min.

[0029] (3) Using metal organic chemical vapor deposition technology on SrCe 1-x Yb x o 3-α Preparation of SrCe on thin film surface 1-x Er x o 3-α thin film, the specific process parameters are: the reaction source is cerium acetylacetonate, strontium acetylacetonate, and erbium acetylacetonate, and the temperature of the reaction source is 200 ° C; H 2 The carrier gas flow rate is 100mL / min.

[0030] (4) according to the proces...

Embodiment 2

[0034] (1) ZrO with a length of 60mm, an outer diameter of 15mm and a wall thickness of 2mm 2 Ultrasonic cleaning of ceramic tube surface for 15 minutes, drying;

[0035] (2) Preparation of SrCe on the surface of ceramic tubes by metal-organic chemical vapor deposition technology 1-x Yb x o 3-αthin film; the specific process parameters are: the reaction source is cerium acetylacetonate, strontium acetylacetonate, and ytterbium acetylacetonate, and the temperature of the reaction source is 280°C; H 2 The carrier gas flow rate is 200mL / min.

[0036] (3) Using metal organic chemical vapor deposition technology on SrCe 1-x Yb x o 3-α Preparation of SrCe on thin film surface 1-x Er x o 3-α thin film, the specific process parameters are: cerium acetylacetonate, strontium acetylacetonate, erbium acetylacetonate, reaction source temperature 220 ° C; H 2 The carrier gas flow rate is 150mL / min.

[0037] (4) according to the process of step (2) in SrCe 1-x Er x o 3-α Prepar...

Embodiment 3

[0041] (1) ZrO with a length of 60mm, an outer diameter of 15mm and a wall thickness of 2mm 2 Ultrasonic cleaning of ceramic tube surface for 15 minutes, drying;

[0042] (2) Preparation of SrCe on the surface of ceramic tubes by metal-organic chemical vapor deposition technology 1-x Yb x o 3-α thin film; the specific process parameters are: the reaction source is cerium acetylacetonate, strontium acetylacetonate, and ytterbium acetylacetonate, and the temperature of the reaction source is 400°C; H 2 The carrier gas flow rate is 300mL / min.

[0043] (3) Using metal organic chemical vapor deposition technology on SrCe 1-x Yb x o 3-α Preparation of SrCe on thin film surface 1-x Er x o 3-α thin film, the specific process parameters are: cerium acetylacetonate, strontium acetylacetonate, erbium acetylacetonate, reaction source temperature 260 ° C; H 2 The carrier gas flow rate is 80mL / min.

[0044] (4) according to the process of step (2) in SrCe 1-x Er x o 3-α Prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com