Nb-V-Ti composite reinforced high-strength wear-resistant tank steel plate and production method

A production method and technology of nb-v-ti, which is applied in the metallurgical field, can solve the problems of poor tensile wear resistance, large internal stress and high cost, and achieve the effects of good wear resistance, excellent mechanical properties and improved transportation capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

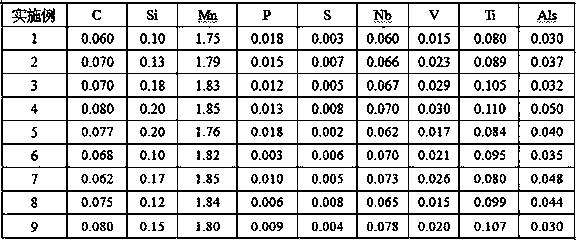

[0019] The chemical composition and mass percentage of the Nb-V-Ti composite strengthened high-strength wear-resistant tank steel plate in this example are shown in Table 1. The production method includes vanadium extraction from vanadium-containing hot metal, semi-steel smelting, LF refining, continuous casting, heating, Rough rolling, finishing rolling, and crimping processes, the specific steps are as follows:

[0020] (1) Smelting and billet production

[0021] A 150t vanadium-extracting converter is used to extract vanadium from molten iron containing vanadium. The semi-steel is smelted for dephosphorization, LF refining and desulfurization, and composition fine-tuning. The cross-section of the billet is 1000mm. The pulling speed of the machine is 1.2m / min. Obtain the casting slab with qualified composition, and its composition is the same as Table 1.

[0022] (2) Controlled rolling and controlled cooling production link

[0023] The cast slabs with the above-mentioned...

Embodiment 2

[0026] The chemical composition and mass percentage of the Nb-V-Ti composite strengthened high-strength wear-resistant tank steel plate in this example are shown in Table 1. The production method includes vanadium extraction from vanadium-containing hot metal, semi-steel smelting, LF refining, continuous casting, heating, Rough rolling, finishing rolling, and crimping processes, the specific steps are as follows:

[0027] (1) Smelting and billet production

[0028] A 150t vanadium-extracting converter is used to extract vanadium from molten iron containing vanadium. The semi-steel is smelted for dephosphorization, LF refining and desulfurization, and composition fine-tuning. The cross-section of the billet is 1500mm. The pulling speed of the machine is 1.1m / min. Obtain the casting slab with qualified composition, and its composition is the same as Table 1.

[0029] (2) Controlled rolling and controlled cooling production link

[0030] The cast slab with the above-mentioned ...

Embodiment 3

[0033] The chemical composition and mass percentage of the Nb-V-Ti composite strengthened high-strength wear-resistant tank steel plate in this example are shown in Table 1. The production method includes vanadium extraction from vanadium-containing hot metal, semi-steel smelting, LF refining, continuous casting, heating, Rough rolling, finishing rolling, and crimping processes, the specific steps are as follows:

[0034] (1) Smelting and billet production

[0035] A 150t vanadium-extracting converter is used to extract vanadium from molten iron containing vanadium. The semi-steel is smelted for dephosphorization, LF refining and desulfurization, and composition fine-tuning. The cross-section of the billet is 1400mm. The pulling speed of the machine is 1.1m / min. Obtain the casting slab with qualified composition, and its composition is the same as Table 1.

[0036] (2) Controlled rolling and controlled cooling production link

[0037] The cast slab with the above-mentioned ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com