Hydrogen resistant motor based on rare earth permanent magnet

A technology of rare earth permanent magnets and hydrogen resistance, which is applied in the manufacture of motor generators, magnetic circuits characterized by magnetic materials, magnetic circuits, etc., can solve the problems of not improving the hydrogen resistance of rare earth permanent magnets, and achieve good hydrogen resistance , improve hydrogen resistance and service life, and promote densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

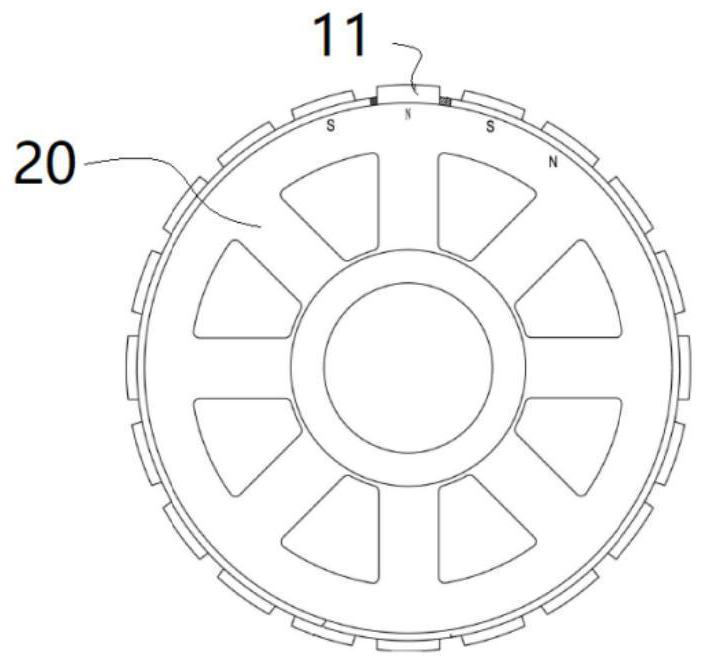

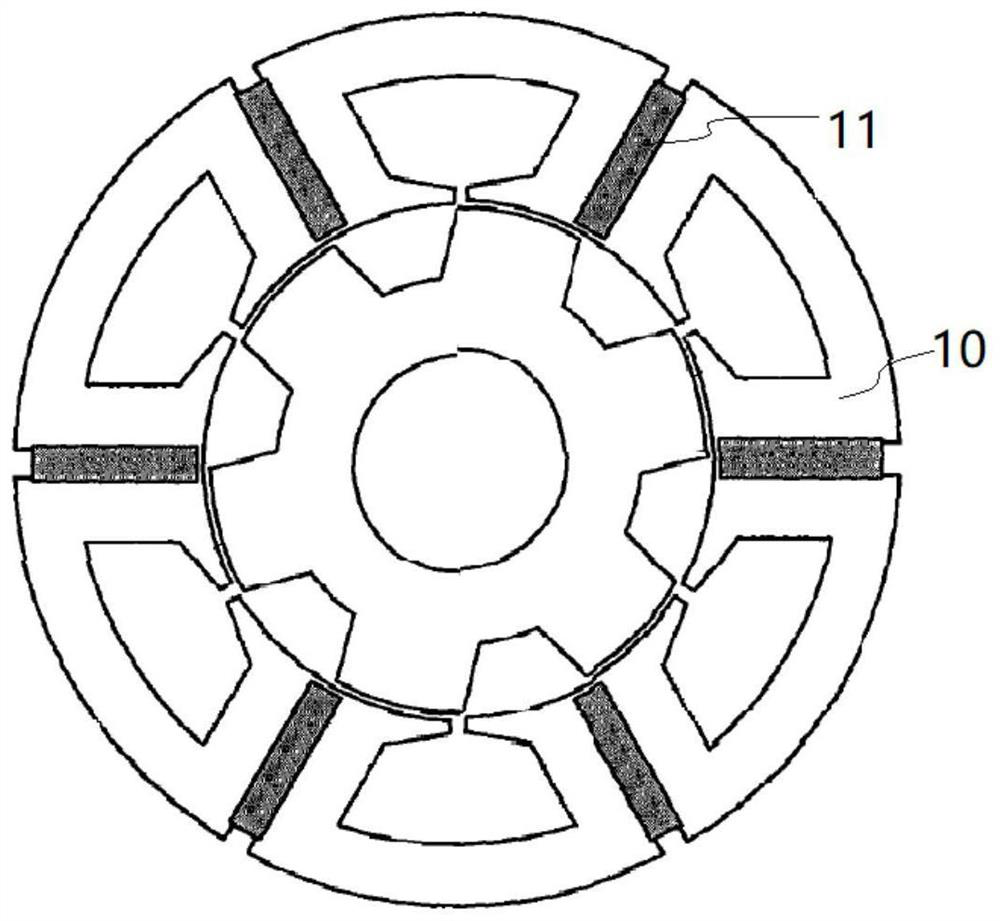

[0041] Such as figure 2 and image 3 As shown, the hydrogen-resistant motor based on rare-earth permanent magnets includes a motor stator 10, a motor rotor 20, and a rare-earth permanent magnet 11. During the movement of the hydrogen-resistant motor, the motor rotor 20 is in motion, and the motor rotor 20 is in a fixed state. Motor stator 10. The magnetic field interaction between the motor stator 10 and the motor rotor 20 generates two kinds of electromagnetic forces acting perpendicular to each other in the plane, thereby realizing the motion of the motor.

[0042]The motor stator 10 is provided with a motor rotor 20, and the motor stator 10 or the motor rotor 20 is provided with a rare earth permanent magnet 11; as figure 2 As shown, the motor rotor 20 is provided with rare earth permanent magnets 11, and the rare earth permanent magnets 11 are evenly distributed on the motor rotor 20; as image 3 As shown, the motor stator 10 is provided with rare earth permanent magn...

Embodiment 2

[0076] Basic content of the present invention is with embodiment 1, and its difference is: the preparation method of hydrogen-resistant rare earth permanent magnet is as follows:

[0077] (1) Smelting: According to the ingredients, the ingredients are smelted in the smelting furnace to obtain Sm 2 (CoCuFeZr) 17 The mass percent content of each element of the magnet is as follows: 50% Co, 23% Sm, 5% Cu, 20% Fe, 1% Zr, 1% impurity; and an ingot is obtained.

[0078] (2) Milling: breaking the ingot and milling to obtain permanent magnet powder, wherein the permanent magnet powder is controlled so that the particle size is controlled at 1 μm-10 μm, and the particle size distribution is such that the mass percentage of 3 μm-5 μm particles is greater than 80%; The powder method can be jet milling, by adding 0.1-3.5mL of antioxidant to every kilogram of permanent magnet powder in the process of jet milling;

[0079] (3) Compression molding: stamping the permanent magnet powder to o...

Embodiment 3

[0092] Basic content of the present invention is with embodiment 1, and its difference is: the preparation method of hydrogen-resistant rare earth permanent magnet is as follows:

[0093] (1) Smelting: According to the ingredients, the ingredients are smelted in the smelting furnace to obtain Sm 2 (CoCuFeZr) 17 The mass percentage of each element of the magnet is as follows: 55% Co, 15% Sm, 6% Cu, 18% Fe, 4% Zr, 2% impurities; and an ingot is obtained.

[0094] (2) Milling: breaking the ingot and milling to obtain permanent magnet powder, wherein the permanent magnet powder is controlled so that the particle size is controlled at 1 μm-10 μm, and the particle size distribution is such that the mass percentage of 3 μm-5 μm particles is greater than 80%; The powder method can be jet milling, by adding 3.5mL of antioxidant to every kilogram of permanent magnet powder in the process of jet milling;

[0095] (3) Compression molding: stamping the permanent magnet powder to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com