Novel corrugated pipe valve seal

A technology of valve sealing and bellows, which is applied in the field of new bellows valve sealing, can solve the problems of high price and easy failure of sealing structure, etc., achieve good medium penetration, improve overall strength and hydrogen resistance, and small opening height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

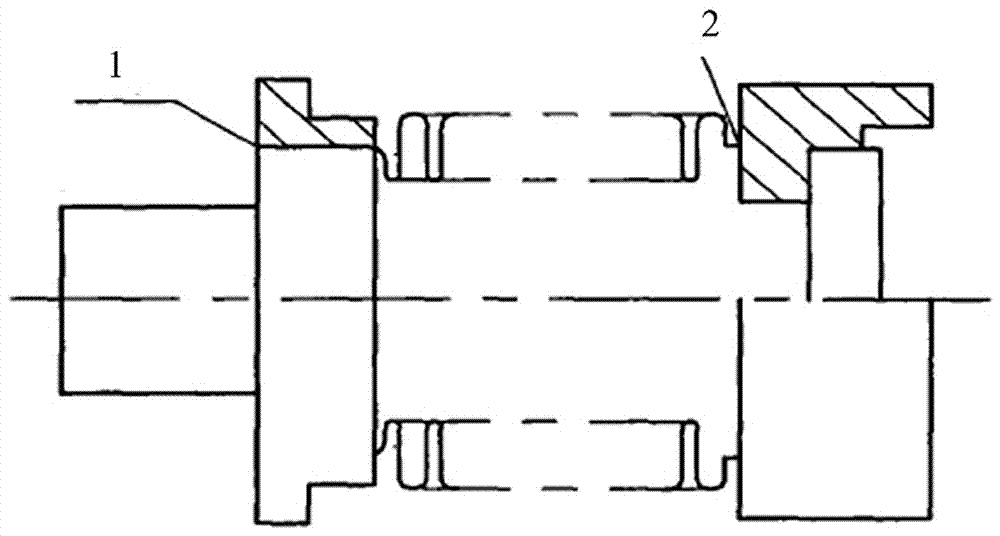

[0011] Preferably, the bellows valve uses the bellows as the outer sealing element, and its structural principle is as follows figure 1 shown. One end of the bellows is welded and fixed on the valve cover and valve seat, and the other end is welded on the valve stem. The up and down movement of the valve stem drives the bellows to compress or stretch, and the bellows acts as an outer seal and elastic element; when the valve is closed, the valve When the stem moves downward, the valve head on the valve stem moves downward and presses the sealing surface. When the valve is closed and the valve is opened, the valve stem is lifted, the valve head leaves the sealing surface, and the valve opens to complete the opening action; the axial stroke of the bellows passes through the valve. The mechanical limit of rod movement is guaranteed.

[0012] Preferably, in order to be able to cut off or open the gas channel in the hydrogen system, a bellows valve structure is used.

[0013] Pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com