A flange forging made of hydrogen-resistant steel and its production process

A flange forging and production process technology, applied in the field of metal forging, can solve the problems of increasing material brittleness, loss, and lack of comprehensive understanding of performance, and achieve the effect of improving hydrogen resistance and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

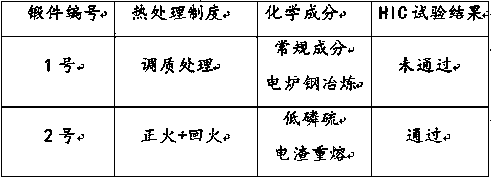

[0013] Implementation case 1: The forgings and flanges produced by using the chemical composition of the above ratio and the production process can successfully pass the HIC test. Taking the most commonly used 16Mn (HIC) hydrogen-resistant steel as an example, the specific experiment is as follows:

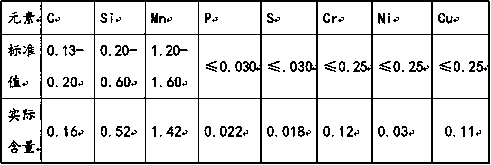

[0014] Table 1 is the conventional 16Mn material, and Table 2 is the chemical composition ratio of the steel with high hydrogen resistance provided by the present invention, and its ratio is as follows:

[0015] Table 1 Chemical composition of 16Mn % Melting furnace number: 3655665

[0016]

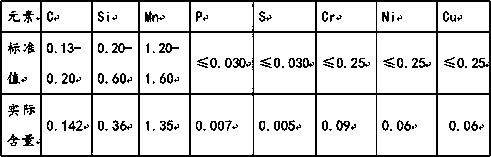

[0017] Table 2 Chemical composition of 16Mn (HIC) % Melting furnace number: 3655632

[0018]

[0019] The two test forgings are heat treated separately. The No. 1 test forging is subjected to quenching and tempering heat treatment according to the conventional requirements. The quenching heating temperature is 920°C±10°C, cooled in a liquid medium, and tempered at 650°C±10°C for 3 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com