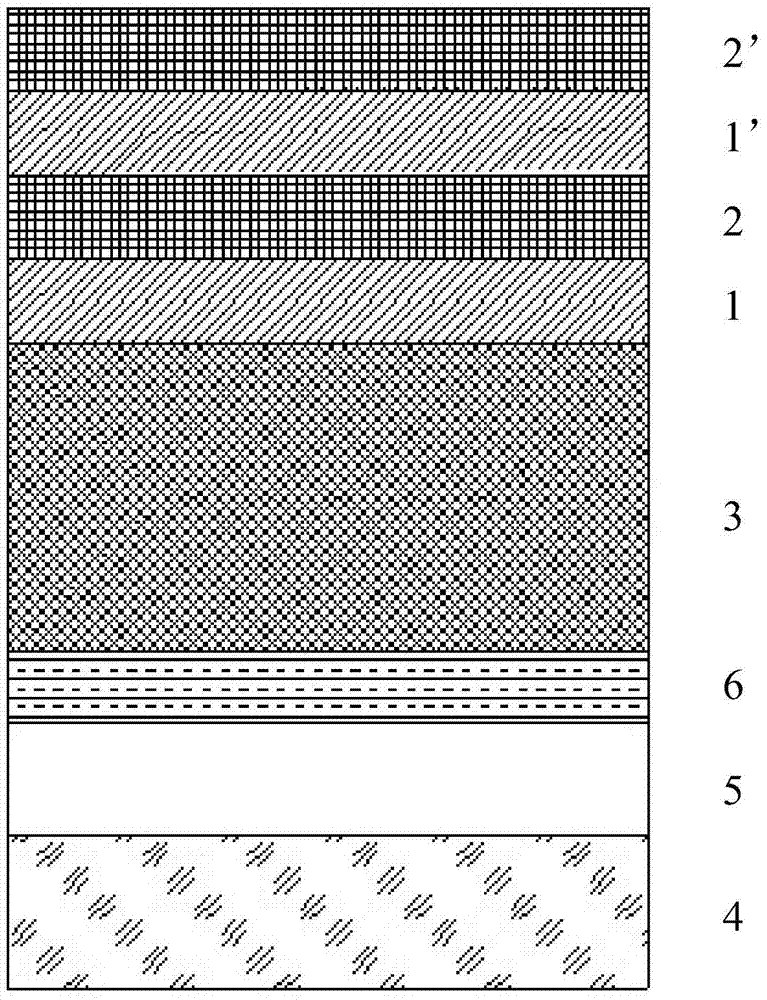

a cr 2 o 3 and al 2 o 3 Composite gradient hydrogen barrier coating and its preparation method and application

A composite coating and coating technology, applied in chemical instruments and methods, coatings, lighting and heating equipment, etc., can solve problems affecting coating reliability, affecting coating material density and hydrogen barrier properties, etc. High resistance, improved hydrogen resistance, and controllable thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Polish the inner surface of the martensitic stainless steel tube 3 of the high-temperature vacuum collector tube to a roughness of 1 μm;

[0035] (2) Using metal-organic chemical vapor deposition technology to prepare Cr on the inner surface of stainless steel tube 3 2 O 3 Coating; the specific process parameters are: reaction source temperature 150℃; carrier gas flow rate 200ml / min;

[0036] (3) Using metal-organic chemical vapor deposition technology to prepare Al on the inner surface of stainless steel tube 3 2 O 3 Coating; the specific process parameters are: reaction source temperature 100℃; carrier gas flow rate is 100ml / min;

[0037] (4) Repeat the above step (2);

[0038] (5) Repeat the above step (3);

[0039] Finally, a multilayer Cr with a thickness of about 0.5μm is obtained 2 O 3 And Al 2 O 3 Composite gradient hydrogen barrier coating.

[0040] Determination of multi-layer Cr 2 O 3 And Al 2 O 3 The H of the composite gradient hydrogen barrier coating at 400℃ 2 Th...

Embodiment 2

[0042] (1) Polish the inner surface of the austenitic stainless steel tube 3 of the high-temperature vacuum collector tube to a roughness of 0.5 μm;

[0043] (2) Using metal-organic chemical vapor deposition technology to prepare Cr on the inner surface of stainless steel tube 3 2 O 3 Coating; specific process parameters are: reaction source temperature 180°C; carrier gas flow rate 200ml / min;

[0044] (3) Using metal-organic chemical vapor deposition technology to prepare Al on the inner surface of stainless steel tube 3 2 O 3 Coating; the specific process parameters are: reaction source temperature 120°C; carrier gas flow rate 150ml / min;

[0045] (4) Repeat the above step (2);

[0046] (5) Repeat the above step (3);

[0047] Finally, a multilayer Cr with a thickness of about 1μm is obtained 2 O 3 And Al 2 O 3 Composite gradient hydrogen barrier coating.

[0048] Determination of multi-layer Cr 2 O 3 And Al 2 O 3 The H of the composite gradient hydrogen barrier coating at 400℃ 2 The perm...

Embodiment 3

[0050] (1) Polish the inner surface of the austenitic stainless steel tube 3 of the high-temperature vacuum collector tube to a roughness of 0.3μm;

[0051] (2) Using metal-organic chemical vapor deposition technology to prepare Cr on the inner surface of stainless steel tube 3 2 O 3 Coating; specific process parameters are: reaction source temperature 200℃; carrier gas flow rate 200ml / min;

[0052] (3) Using metal-organic chemical vapor deposition technology to prepare Al on the inner surface of stainless steel tube 3 2 O 3 Coating; the specific process parameters are: reaction source temperature 160℃; carrier gas flow rate 80ml / min;

[0053] (4) Repeat the above step (2);

[0054] (5) Repeat the above step (3);

[0055] Finally, a multilayer Cr with a thickness of about 0.8μm is obtained 2 O 3 And Al 2 O 3 Composite gradient hydrogen barrier coating;

[0056] Determination of multi-layer Cr 2 O 3 And Al 2 O 3 The H of the composite gradient hydrogen barrier coating at 400℃ 2 The permea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com