Method and equipment for resource utilization of dewatered sludge in sewage plant by supercritical treatment

A technology for dewatering sludge and treating resources, which is applied in the field of resource utilization in the supercritical treatment of dewatered sludge in sewage plants to achieve the effects of saving energy loss, strong applicability, and improving energy utilization.

Inactive Publication Date: 2011-12-07

HOHAI UNIV

View PDF8 Cites 29 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The present invention proposes a method and equipment for resource utilization of dewatered sludge in a sewage plant through supercritical treatment. And the treatment products are used as resources to achieve a win-win situation for the environment and energy, which not only solves the energy problem generated by sludge, but also recovers resources from sludge

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

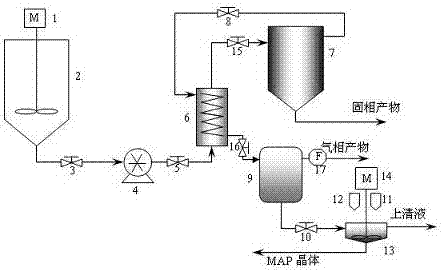

[0028] Put the dewatered sludge (water content 77%~85%) from the sewage plant in the sludge storage tank 2, start the high-speed stirring motor 1, and keep it in the high-speed stirring state.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

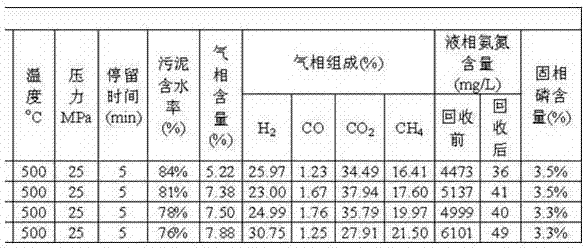

The invention discloses a method and equipment for supercritical treatment and resource utilization of dewatered sludge of a sewage plant. The method is characterized in that: the dewatered sludge (the water content is 77 to 85 percent) is directly treated in a supercritical water vaporization mode, the flowability of the sludge is improved through a high-speed stirring device, blockage of a tubular reactor is prevented by adopting a high-pressure fluidized bed device, high heat of a gas-liquid separation process is fully utilized, and the low-temperature sludge is heated by using a heat exchanger; and the liquid phase product with high ammonia nitrogen content is directly recycled by a magnesium ammonium phosphate (MAP) method. The method has the advantages that: any moisture is not added in the vaporization process, and the sludge treatment efficiency is high; the heat can be utilized in the process; ammonia nitrogen in the liquid phase product is timely reclaimed so as to reduce secondary pollution; the reclaimed supernate can be recycled, the periodically discharged solid phase product with low heavy metal content can be directly used as a phosphate fertilizer, and the solid phase product with high heavy metal content can be used as an adsorbent; and the treatment expense of the whole system is reduced by resource utilization of the liquid phase product and the solid phaseproduct.

Description

technical field [0001] The invention relates to a method and equipment for resource utilization of dewatered sludge in a sewage plant by supercritical treatment, in particular to a method for direct supercritical water treatment of dewatered sludge (moisture content 77-85%) by using the characteristics of supercritical water Gasification treatment produces combustible gas containing a large amount of hydrogen; and then recovers the ammonia nitrogen in the liquid phase product. After recovery, the supernatant can be directly irrigated with surrounding green belts or surrounding landscape plant belts, and the solid product can be directly landfilled or treated with phosphate fertilizer The utility model can be utilized in various forms; the high cost of supercritical water gasification sludge can be reduced by recycling solid and liquid products, which belongs to the field of resources and environment. Background technique [0002] Sludge is an inevitable product in the proces...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C02F11/00C02F11/10C10J3/54C10J3/56C01B25/45C05F7/00B09B3/00B01J20/02

CPCY02A40/20Y02P20/54

Inventor 朱伟徐志荣李磊张会文

Owner HOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com